Liquid crystal sealing agent, method for manufacturing liquid crystal display panel using the liquid crystal sealing agent, and liquid crystal display panel

A liquid crystal sealant and a general formula technology, applied in chemical instruments and methods, other chemical processes, optics, etc., can solve problems such as reduced bonding strength, low liquid crystal solubility, and reduced quality of liquid crystal display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0364] (Preparation method of liquid crystal sealant)

[0365] The method of preparing the liquid crystal sealing compound of this invention is not specifically limited, A well-known technique can be used. In addition, examples of means for mixing the components of the liquid crystal sealing agent include twin-arm mixers, roll kneaders, twin-screw extruders, ball mill kneaders, and planetary mixers, but are not particularly limited, and known kneading The machine will do. The liquid crystal sealing agent mixed appropriately by any method is filtered with a filter to remove impurities. Then, after vacuum defoaming treatment, it is sealed and filled into glass bottles or plastic containers, and stored and transported as needed.

[0366] (Manufacturing method of liquid crystal display panel)

[0367] Next, the method of manufacturing the liquid crystal display panel of the present invention will be described. The liquid crystal sealing compound of the above-mentioned present ...

Embodiment

[0383] Hereinafter, the present invention will be described in more detail with reference to Examples and Comparative Examples of the present invention. However, this invention is not limited to the form shown below.

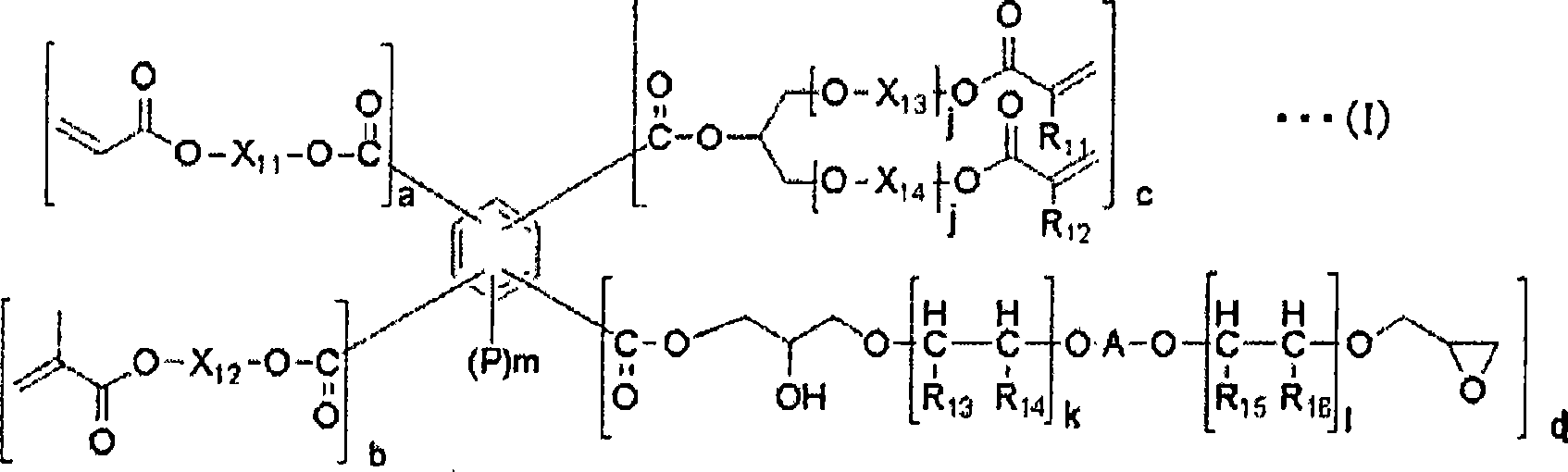

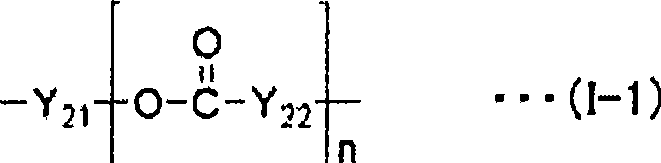

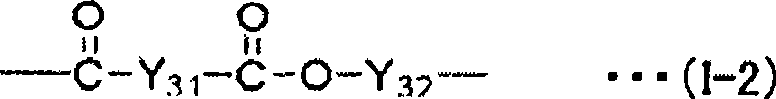

[0384] (a) Compounds containing (meth)acryloyl and glycidyl groups in the molecule and having a number average molecular weight of 500-2000

[0385] As (a) component, the compound synthesize|combined in the following synthesis examples 1-10 was used, respectively. Among them, the compounds synthesized in Synthesis Examples 1 to 4 correspond to the first (a) component, and the compounds synthesized in Synthesis Examples 7 to 10 correspond to the second (a) component. In addition, the compounds synthesized in Synthesis Examples 5 and 6 have predetermined organic groups in their molecules, but their number average molecular weights are outside the range of 500 to 2,000.

[0386] In each synthesis example, the acid value of the reaction mixture sampled at any stag...

Synthetic example 1

[0389] In Synthesis Example 1, compound A1 containing a (meth)acryloyl group and a glycidyl group was synthesized by reacting glycerin acrylate methacrylate-modified phthalic acid with bisphenol F diglycidyl ether.

[0390] First, in a 500ml four-necked flask equipped with a stirrer, a gas inlet tube, a thermometer, and a condenser tube, 74 g (0.5 mol) of phthalic anhydride, 271 g (0.5 mol) of glycerol acrylate methacrylate, and 0.7 g of tributylammonium bromide and 0.5 g of phenothiazine as a polymerization inhibitor were mixed, heated to 80° C., and reacted for 1 hour, and then heated to 130° C., and reacted for 2 hours.

[0391] 276 g (0.4 mol) of the reaction product, bisphenol F type epoxy resin (EPOTOHTOYDF-8170C, manufactured by Tohto Chemical Co., Ltd.) 125 g (0.4 mol), 0.6 g of tributylammonium bromide as a catalyst, and 0.6 g of tributylammonium bromide as a catalyst. Add 0.1 g of hydroquinone monomethyl ether as a polymerization agent into a 500 ml four-necked flask...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com