Slurry type heavy calcium carbonate of added porcelain clay for making paper and its preparing method

A technology of heavy calcium carbonate and heavy calcium carbonate powder is applied in the field of papermaking, which can solve the problems of incompatibility with the production requirements of high-speed paper machines, unstable viscosity, poor rheology, etc., and improve ink absorption and printability. , Improve the mixing performance, improve the appearance of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

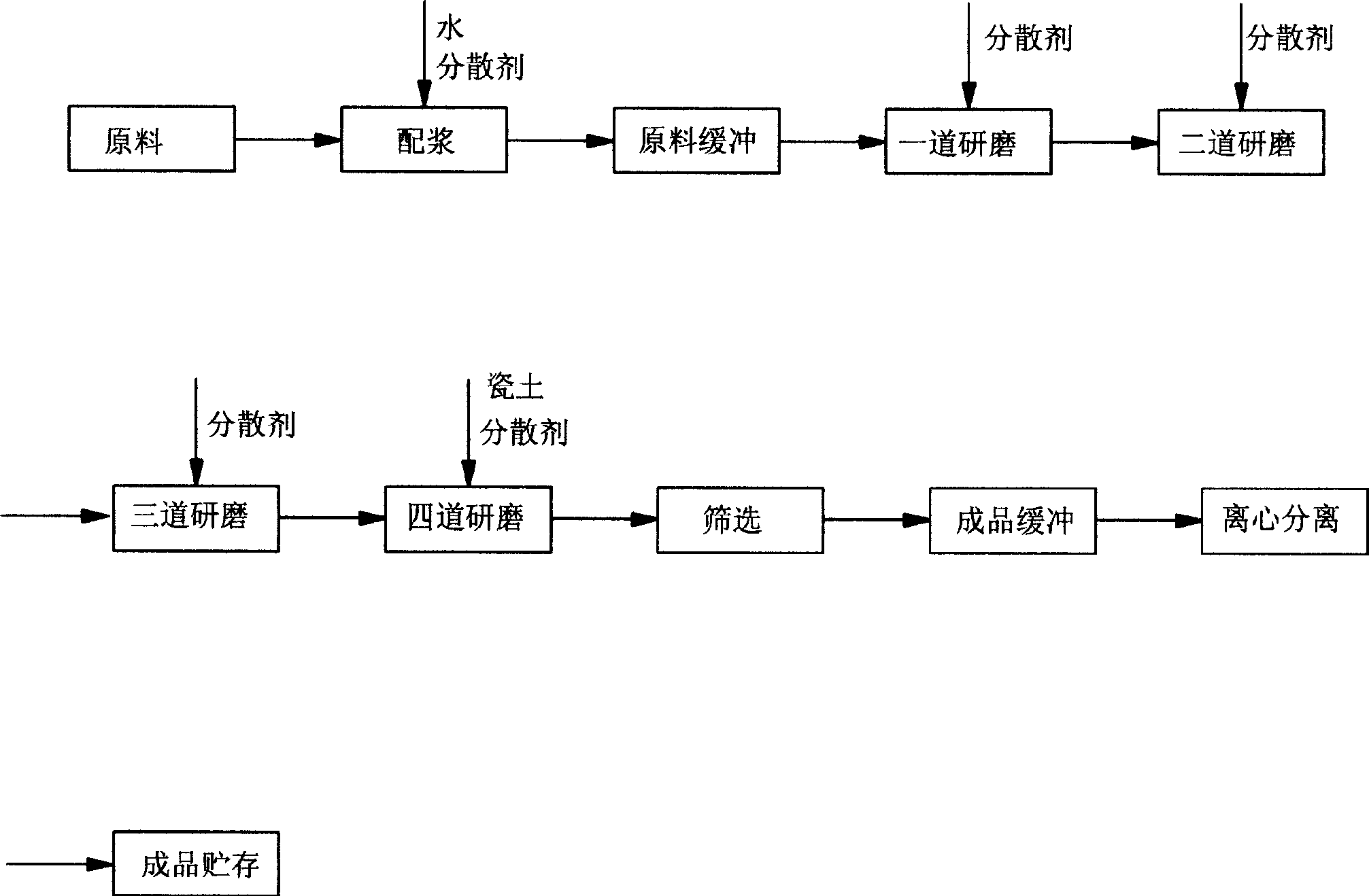

Method used

Image

Examples

Embodiment 1

[0016] Material preparation: 800 kg of 400-mesh heavy calcium carbonate powder, 16 kg of dispersant sodium polyacrylate, and 200 kg of china clay are used as raw materials;

[0017] Mixing: add 4.0 kg of water and dispersant to a container with a stirrer, start stirring and put in 800 kg of calcium carbonate powder for slurry mixing;

[0018] Raw material buffering: put the slurry into the raw material buffer tank and start stirring for raw material buffering;

[0019] Grinding: Turn on each grinding machine, and input the raw material slurry into each grinding machine, and gradually add the dispersant sodium polyacrylate dropwise into each grinding machine as the slurry enters, and one of the grinding machine dispersant sodium polyacrylate The dropping amount of the grinding dispersant sodium polyacrylate is 3.0 kg; the dropping amount of the second grinding dispersant sodium polyacrylate is 3.0 kg; the dropping amount of the third grinding dispersant sodium polyacrylate is 3...

Embodiment 2

[0026] Step is with embodiment one, wherein

[0027] When preparing materials, use 720 kg of heavy calcium carbonate powder, 14 kg of sodium polyacrylate as a dispersant, and 180 kg of china clay; when mixing slurry, add 3.6 kg of water and dispersant to a container with a stirrer, start stirring and put 800 Kilogram of calcium carbonate powder for pulping;

[0028] And when grinding, the dripping amount of the dispersant sodium polyacrylate in the first grinder is 2.6 kg; the dripping amount of the dispersant sodium polyacrylate in the second grinder is 2.6 kg; The amount is 2.6 kg; the dripping amount of the four-way grinder dispersant sodium polyacrylate is 2.6 kg, and at the same time, 180 kg of china clay is gradually and evenly added to the four-way grinder with the slurry entering;

[0029] Solid content 75% in the prepared slurry heavy calcium carbonate, particle ratio 98.3% less than 2um particle size, particle ratio 83.2% less than 1um particle size, 325 mesh sieve ...

Embodiment 3

[0031]Material preparation: The raw materials are 850 kg of heavy calcium carbonate powder, 18 kg of dispersant sodium polyacrylate, and 300 kg of china clay;

[0032] Mixing: add 4.5 kg of water and dispersant to a container with a stirrer, start stirring and put in 850 kg of calcium carbonate powder for slurry mixing;

[0033] Grinding: Turn on each grinding machine, and input the raw material slurry into each grinding machine, and gradually add the dispersant sodium polyacrylate dropwise into each grinding machine as the slurry enters, and one of the grinding machine dispersant sodium polyacrylate The dropping amount of the grinding dispersant sodium polyacrylate is 3.6 kg; the dropping amount of the second grinding dispersant sodium polyacrylate is 3.5 kg; the dropping amount of the third grinding dispersant sodium polyacrylate is 3.4 kg; the fourth grinding machine dispersant polyacrylic acid The dripping amount of sodium is 3.0 kg, and at the same time, 300 kg of china c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com