Method for preparing lead-aluminum composite anode plate

An anode plate and aluminum composite technology, applied in the field of electrolysis, can solve the problems of failure to apply industrial production practices, short service life, affecting the quality of electrolytic zinc, etc., and achieve the effect of significant power saving, good power saving and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

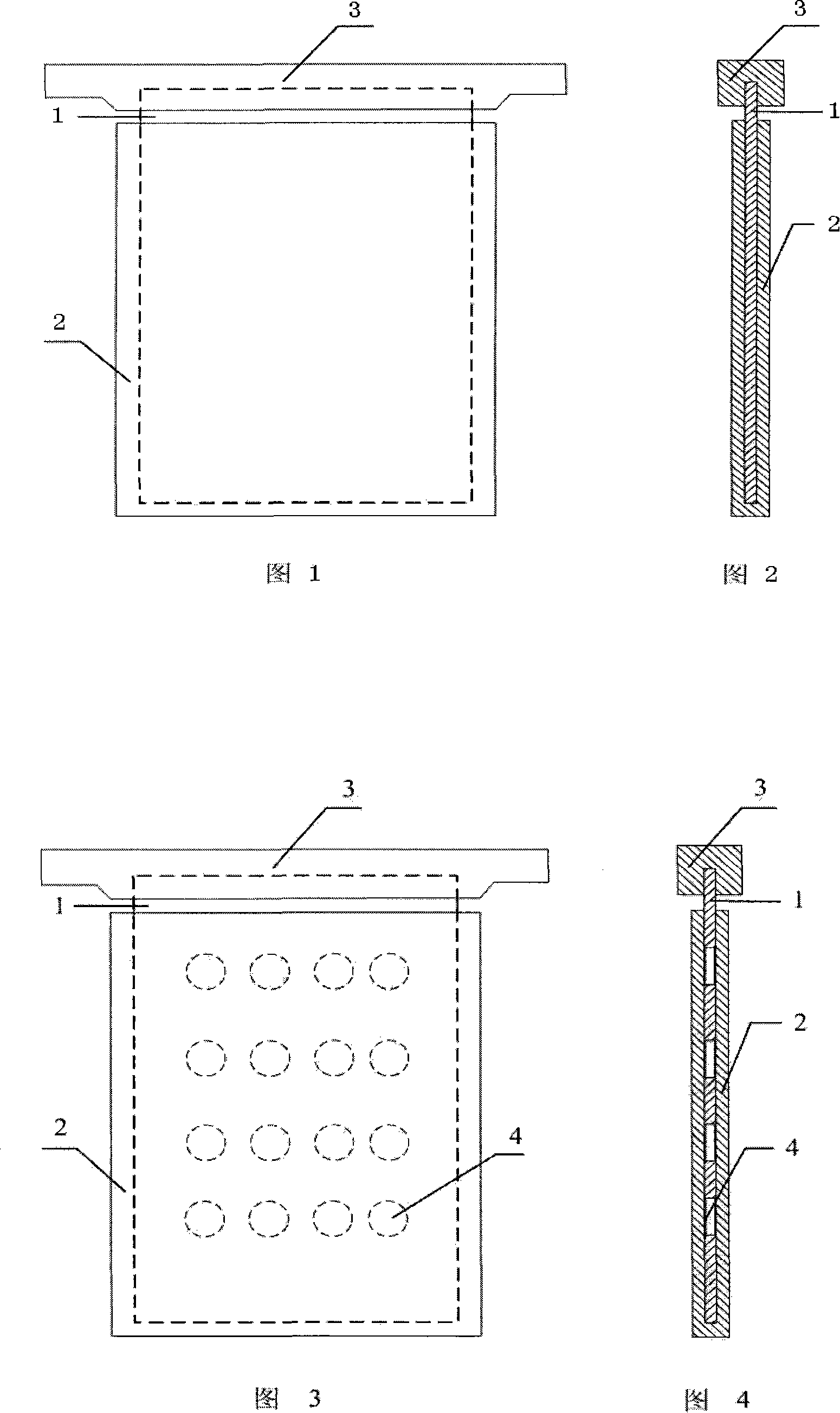

[0015] First select a pure aluminum plate with a thickness of 0.5mm, cut it into a length of 120mm and a width of 90mm, evenly distribute the holes in the middle of the aluminum plate, acid-etch the surface, remove the oxide film, then coat a layer of Zn on the surface of the aluminum plate, place it in the mold, and evenly spread the pure lead Casting around the aluminum plate to wrap the aluminum plate, the top of the aluminum plate is exposed 10mm, forming a wrapping layer, the thickness of each side of the aluminum plate is 3mm of pure lead or lead-silver alloy, the two sides and the bottom of the aluminum plate are pure lead, and its width is 3mm, the above plate is rolled, The thickness of pure lead on each side of the aluminum plate is 1 mm, and the copper conductive beams are connected and fixed on the aluminum plate to form a lead-aluminum composite anode plate.

Embodiment 2

[0017] First choose 5.0mm 6xxx series aluminum alloy plates, cut into length 2000mm and width 1000mm, acid-etch the surface of the aluminum plate to remove the oxide film, then coat a layer of Sn on the surface of the aluminum plate, hang it in the mold, and put the lead-silver alloy (silver 0.1%, The rest is lead) evenly cast around the aluminum plate to wrap the aluminum plate, the top of the aluminum plate is exposed 200mm, forming a wrapping layer, the thickness of the lead-silver alloy on each side of the aluminum plate is 25mm, the two sides and the bottom of the aluminum plate are lead-silver alloy, and its width is 25mm. Rolling is carried out so that the thickness of the lead-silver alloy on each side of the aluminum plate is 5mm, and the copper conductive beam is connected and fixed on the aluminum plate to form a lead-aluminum composite anode plate.

Embodiment 3

[0019] First choose 2.0mm 1xxx series aluminum alloy plate, cut it into length 1010mm and width 650mm, evenly distribute the holes in the middle of the aluminum plate, acid etch the surface, remove the oxide film, then coat a layer of Mg on the surface of the aluminum plate, place it in the mold, and put the lead silver Alloy (silver 0.5%, the rest is lead) is evenly cast around the aluminum plate to wrap the aluminum plate, the top of the aluminum plate is exposed 80mm, forming a wrapping layer, the thickness of the lead-silver alloy on each side of the aluminum plate is 15mm, the two sides and the bottom of the aluminum plate are lead-silver alloy, the The thickness of the lead-silver alloy on each side of the aluminum plate is 2mm, and the copper conductive beam is connected and fixed on the aluminum plate to form a lead-aluminum composite anode plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com