Corrosion and scale inhibitor for cooling water in petrochemical industry

A technology of corrosion and scale inhibitors and corrosion inhibitors, which is applied in the field of high-efficiency composite corrosion and scale inhibitors and cooling water scale and corrosion inhibitors. It can solve the problems that calcium phosphate scale cannot be effectively inhibited and improve the reuse rate. , best market value and environmental protection value, excellent corrosion and scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

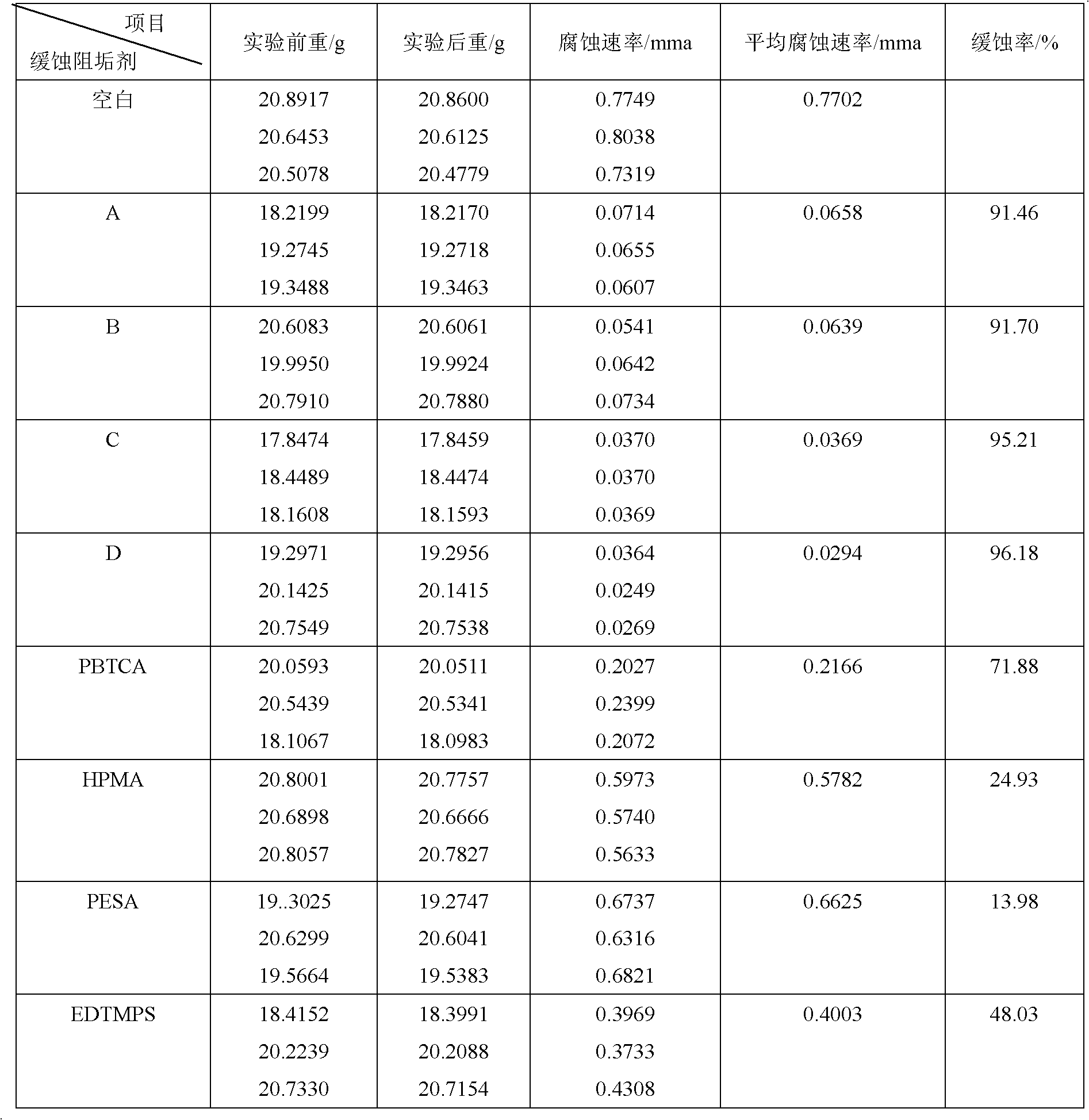

Embodiment 1

[0026] The specific component distribution ratio of the slow-release scale inhibitor is: 30g 2-phosphonobutane-1,2,4-tricarboxylic acid, 1g zinc chloride, 28.6g sodium ethylenediamine tetramethylene phosphonate, 0.5 g sodium hexametaphosphate, 20g sodium polyepoxysuccinate, 5g citric acid, 2g polyoxyethylene ether imidazoline, 45g deionized water.

[0027] The specific preparation process is: first add organic carboxylate corrosion and scale inhibitor, then add zinc salt; after the zinc salt is fully dissolved, then add organic polyphosphonic acid corrosion and scale inhibitor, polymer scale inhibitor, metal ion Chelating agent, surfactant, and finally add deionized water to the prescription amount, stir and mix thoroughly to obtain the compound product - slow-release scale inhibitor A.

Embodiment 2

[0029] The specific component distribution ratio of the slow-release scale inhibitor is: 30g 2-phosphonobutane-1,2,4-tricarboxylic acid, 2g zinc chloride, 20g sodium ethylenediamine tetramethylene phosphonate, 10g poly Sodium epoxy succinate, 1g sodium hexametaphosphate, 2g citric acid, 4g polyoxyethylene ether imidazoline, 41.5g deionized water.

[0030] The specific preparation process is: first add organic carboxylate corrosion and scale inhibitor, then add zinc salt; after the zinc salt is fully dissolved, then add organic polyphosphonic acid corrosion and scale inhibitor, polymer scale inhibitor, metal ion Chelating agent, surfactant, and finally add deionized water to the prescription amount, stir and mix thoroughly to obtain the compound product - slow-release scale inhibitor B.

Embodiment 3

[0032]The specific component distribution ratio of the slow-release scale inhibitor is: 20g 2-phosphonobutane-1,2,4-tricarboxylic acid, 0.5g zinc chloride, 5g sodium ethylenediamine tetramethylene phosphonate, 8g Sodium polyepoxysuccinate, 0.2g sodium hexametaphosphate, 0.5g citric acid, 1g polyoxyethylene ether imidazoline, 40g deionized water.

[0033] The specific preparation process is: first add organic carboxylate corrosion and scale inhibitor, then add zinc salt; after the zinc salt is fully dissolved, then add organic polyphosphonic acid corrosion and scale inhibitor, polymer scale inhibitor, metal ion Chelating agent, surfactant, and finally add deionized water to the prescription amount, stir and mix thoroughly to obtain the compound product - slow-release scale inhibitor C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com