Preparation method of flaky nanoholes carbon and carbon nanotube composite

A technology of nanoporous carbon and carbon nanotubes, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the cumbersome preparation process and the difficulty in realizing the chemical composition and microstructure of two-dimensional nanocarbon materials Problems such as synchronous regulation and difficulty in wide application have achieved the effects of wide application prospects, enhanced electrical conductivity, and developed pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

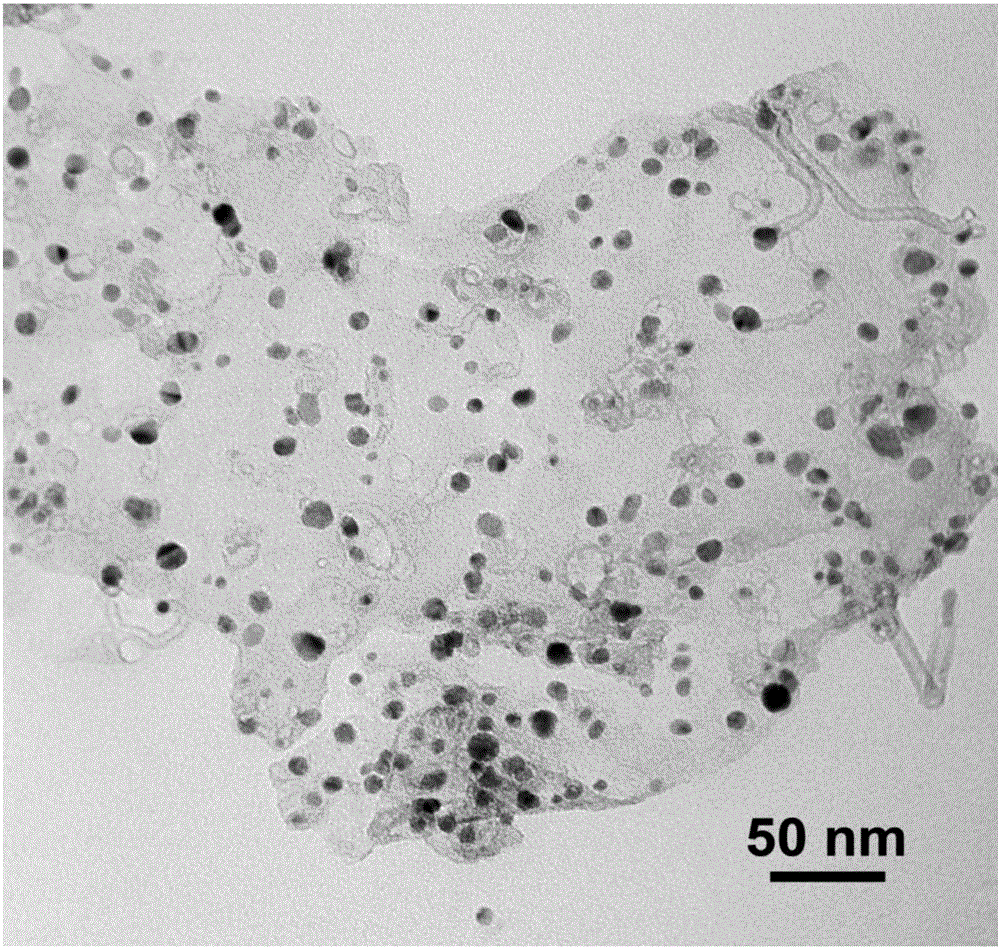

[0022] a. Ultrasonic dispersion of 0.5g montmorillonite in 50mL cobalt nitrate aqueous solution (0.07M), ultrasonic separation for 30 minutes and washing with ethanol twice to obtain cobalt ion-modified montmorillonite; cobalt ion-modified montmorillonite Ultrasonic disperse in 80mL cobalt nitrate ethanol solution (0.125M), add 80mL dimethylimidazole methanol solution (0.5M) after ultrasonication for 30 minutes, stir for 5 minutes, and let the mixed dispersion stand at room temperature for 24 hours; After the end, the product was centrifuged, washed twice with ethanol, and dried at 80°C to obtain ZIF-67 intercalated montmorillonite powder.

[0023] b. Heat the ZIF-67 intercalated montmorillonite powder prepared in step a to 900°C in nitrogen flow, and control the heating rate to 5°C min -1 , The calcination time is 2 hours. After the reaction, a black solid powder was obtained.

[0024] c. Soak the black solid powder prepared in step b in hydrofluoric acid, filter and separa...

Embodiment 2

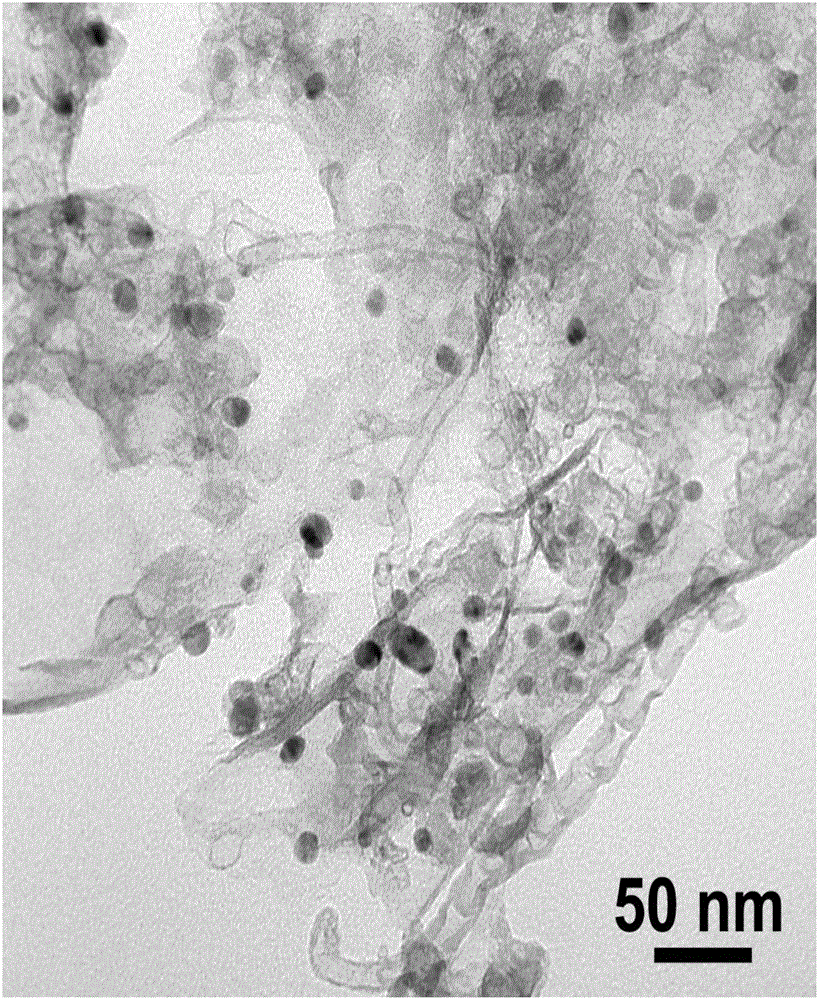

[0026] a. Ultrasonic dispersion of 0.5g montmorillonite in 50mL cobalt nitrate (0.035M) and nickel nitrate (0.035M) mixed aqueous solution, ultrasonic separation for 30 minutes and washing with ethanol twice to obtain cobalt / nickel ion modified montmorillonite Soil; the montmorillonite modified by cobalt ions was ultrasonically dispersed in 80mL cobalt nitrate (0.0625M) and nickel nitrate (0.0625M) mixed ethanol solution, and after 30 minutes of ultrasound, 80mL dimethylimidazole methanol solution (0.5M) was added, After stirring for 5 minutes, the mixed dispersion was left to stand at room temperature for 24 hours; after the reaction, the product was centrifuged, washed twice with ethanol, and dried at 80°C to obtain CoNi-ZIF intercalated montmorillonite powder.

[0027] B, with step b in embodiment 1;

[0028] c. Soak the black solid powder prepared in step b in hydrofluoric acid, filter and separate after reacting for 12 hours, wash 3 times with deionized water, and dry at ...

Embodiment 3

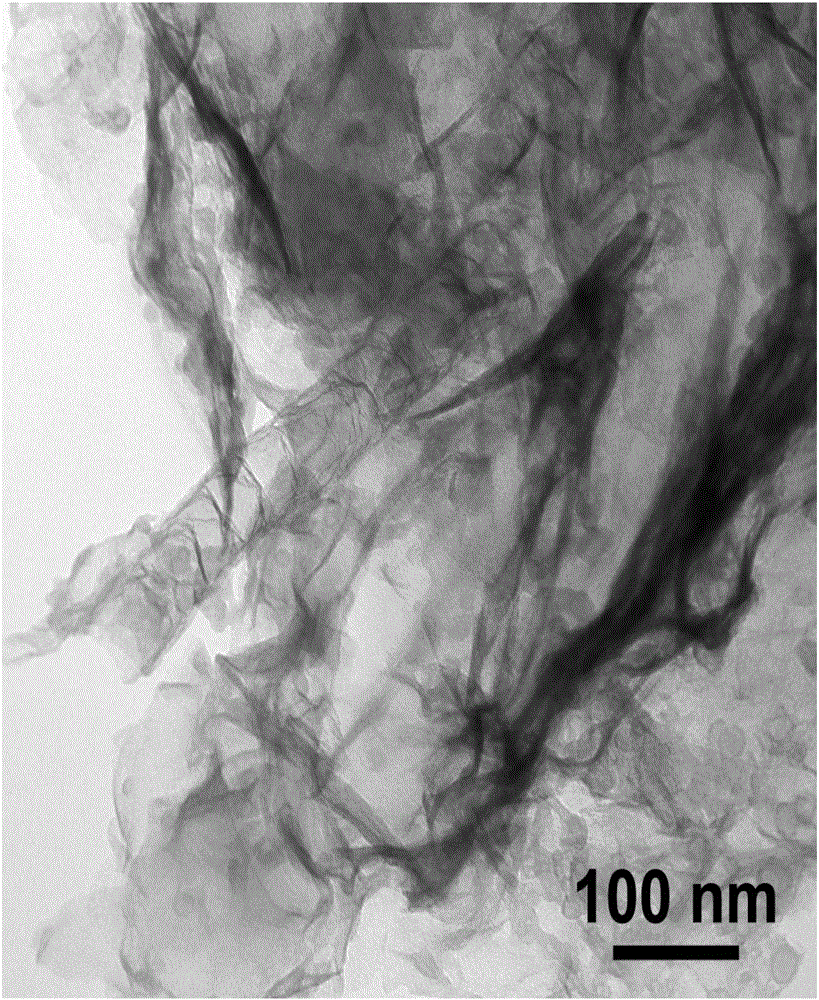

[0030] a. Ultrasonic dispersion of 0.5g montmorillonite in 50mL zinc nitrate (0.035M) and nickel nitrate (0.035M) mixed aqueous solution, ultrasonic separation for 30 minutes and washing with ethanol twice to obtain zinc / nickel ion modified montmorillonite Soil; the montmorillonite modified by cobalt ions was ultrasonically dispersed in 80mL of zinc nitrate (0.0625M) and nickel nitrate (0.0625M) mixed ethanol solution, and after 30 minutes of ultrasound, 80mL of dimethylimidazole methanol solution (0.5M) was added, After stirring for 5 minutes, the mixed dispersion was left to stand at room temperature for 24 hours; after the reaction, the product was centrifuged, washed twice with ethanol, and dried at 80°C to obtain ZnNi-ZIF intercalated montmorillonite powder.

[0031] B, with step b in embodiment 1;

[0032]c. Soak the black solid powder prepared in step b in hydrofluoric acid, filter and separate after 12 hours of reaction, wash 3 times with deionized water, and dry at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com