Chassis of body of hundred-percent modern city tramcar

A technology for trams and car bodies, applied to the underframe, railway car body parts, transportation and packaging, etc., which can solve the problems that the parts cannot be independently synchronized, the welding process requirements are high, and there are too many welding parts, etc., to achieve Less prone to local fatigue damage, improved repair rate and general use rate, less prone to stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

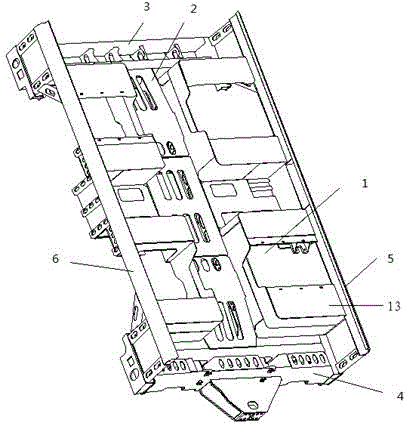

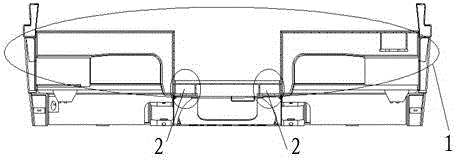

[0026] like figure 1 , figure 2 As shown, a 100% modern urban tram car body chassis includes a corbel 1, a longitudinal beam 2, a first end beam 3, a second end beam 4, a first side beam 5, and a second side beam 6. The aforementioned parts are all welded with high-strength carbon steel materials, and each part is welded separately and then tailor-welded. The corbel beams, longitudinal beams, end beams and side beams can be welded into a box frame structure. The corbel 1 is welded into a closed "bow" box shape, connected with the shock absorbing spring of the bogie, and is one of the main load-bearing points. The longitudinal beams 2 are welded into a closed box-shaped structure, and the two longitudinal beams are arranged in parallel and run through the entire vehicle body, which is beneficial to the transmission of force and connects various components of the vehicle body chassis. As one of the main load-bearing parts, the longitudinal beam 2 itself is welded by high-str...

specific Embodiment 2

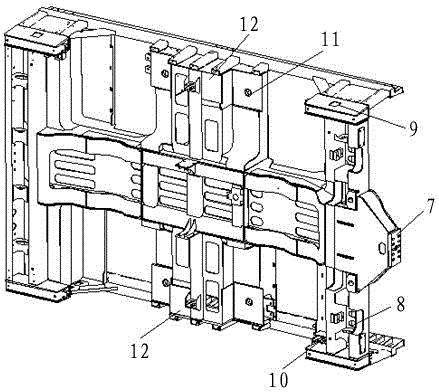

[0029] like Figure 5 As shown, it is another specific scheme of a 100% modern urban tram car body underframe. The welded structure of the second end beam 4 also integrates the hinge mounting seat 7, the traction rod mounting seat 8, the hoisting support 9 and The transverse damper is installed with a support 10, which is convenient for connection and disassembly with other parts. The end beam 4 is connected with the bogie and the traction rod through the traction rod mounting seat 8, and bears the impact force of braking and traction. The hoisting assembly is installed through the hoisting support 9, and the damper is installed through the transverse damper mounting support 10. Hingedly connect other carriages. The first end beam 3 is also replaced with the same structure as the second end beam 4, and the second hinge mounting seat 14, the second traction rod mounting seat 15, the second The second suspension support 16 and the second transverse damper installation support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com