Arc tube boiler with electromagnetic radiation theory structure

An electromagnetic wave and arc-shaped tube technology, which is applied in the boiler field, can solve the problems of no fluid inertia, high maintenance rate, easy deformation of pipe diameter, etc., and achieve the effects of good running inertia, low maintenance cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

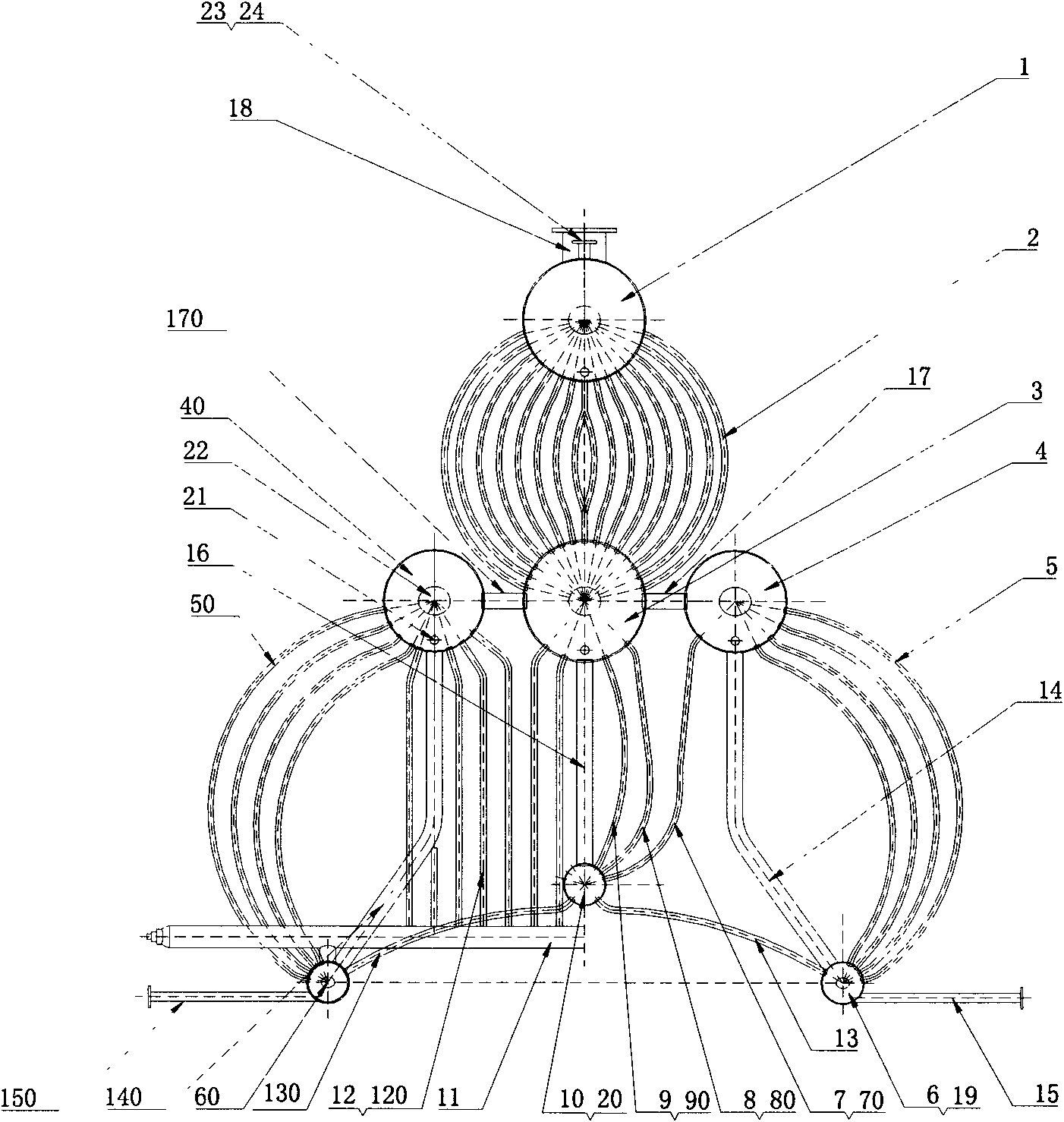

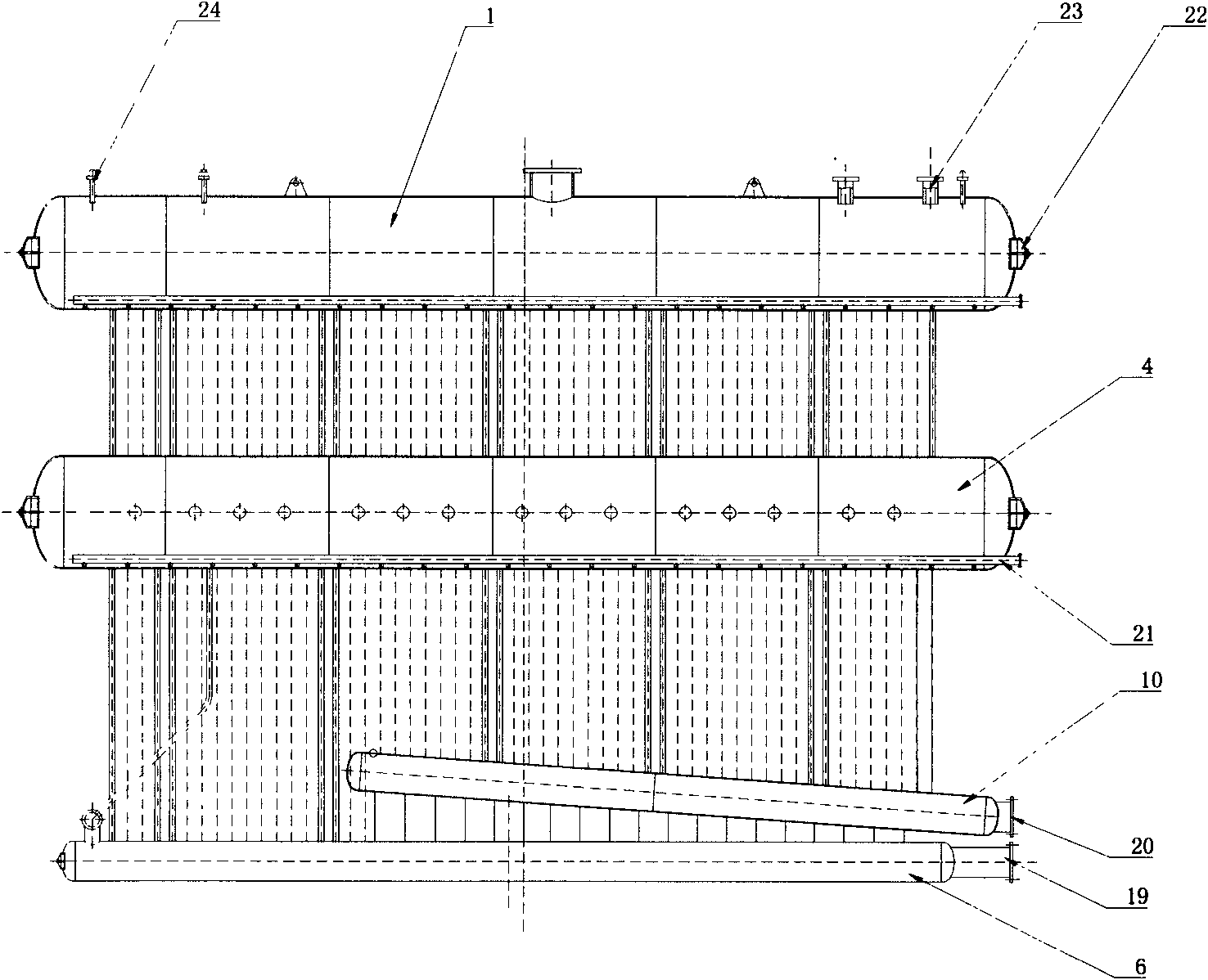

[0024] Such as figure 1 As shown in Figure 3, figure 1 is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of a side view structure of the present invention; FIG. 3 is a schematic diagram of a top view structure of the present invention.

[0025] The present invention is an arc-shaped tube boiler with the principle of electromagnetic wave radiation, which is composed of four boiler drums arranged vertically. The arc-shaped tube boiler is formed according to the principle of electromagnetic wave radiation to form wave beams and focus on energy conversion. The boiler can save a lot of energy and save energy. Burn less row, the purpose of protecting the environment.

[0026] The upper part of the upper drum 1 is provided with a water outlet pipe 18, and the upper drum 1 is connected with the lower drum 3 through the arc-shaped convection pipe 2 with a large curvature radius structure; the lower drum 3 is connected with the middle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com