IBC solar cell string welding strip welding production line and production method thereof

A solar cell and welding production line technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult automatic welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with accompanying drawing.

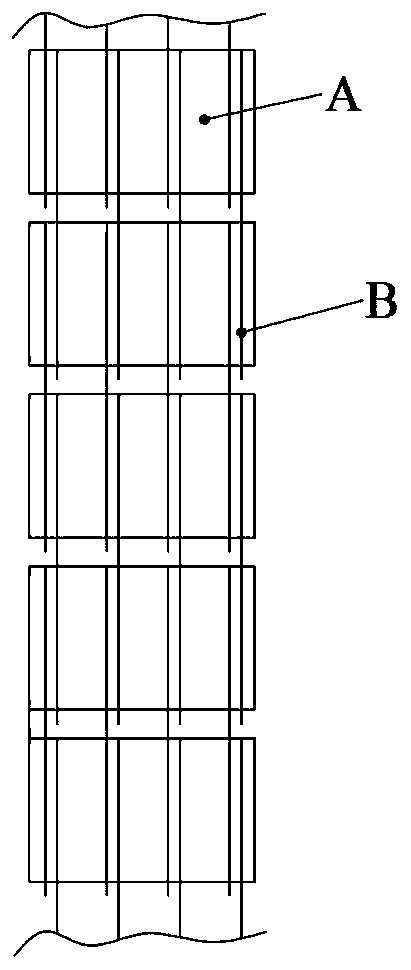

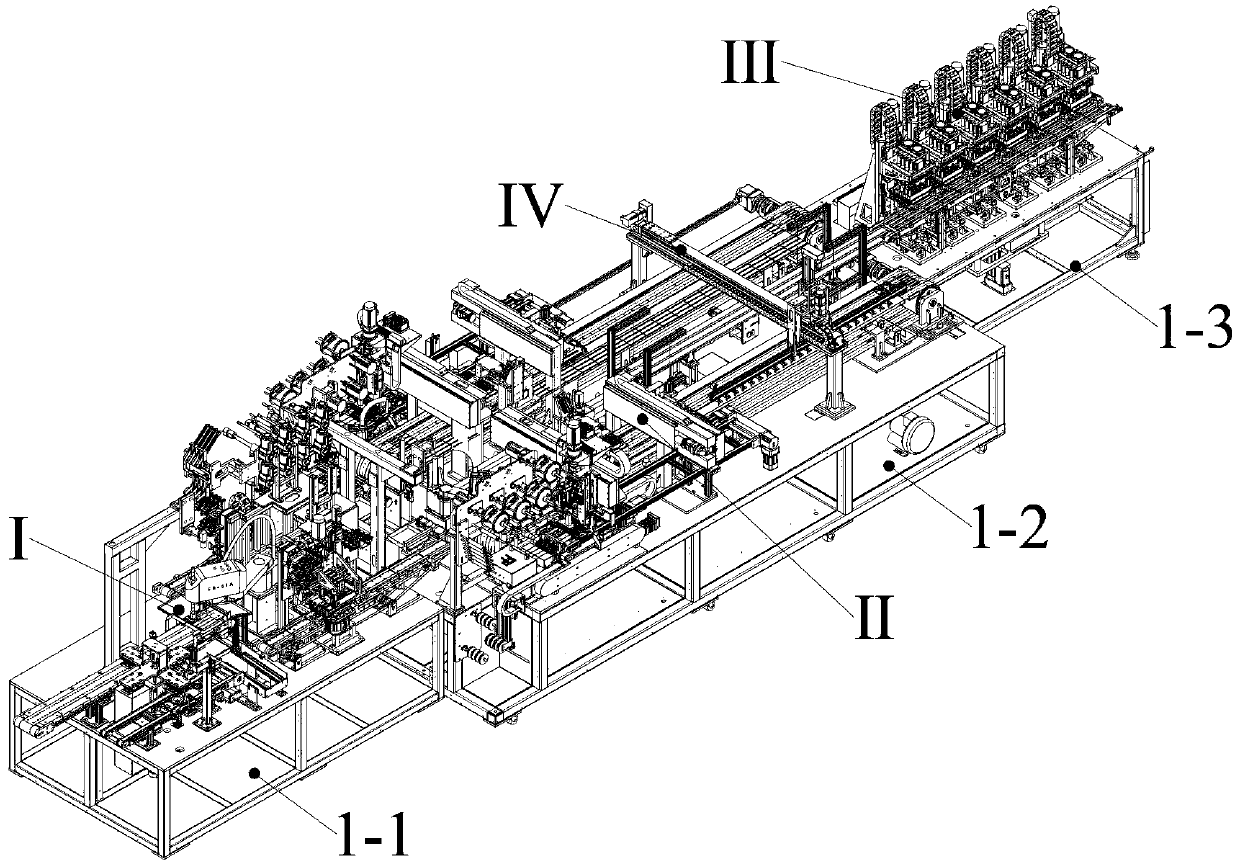

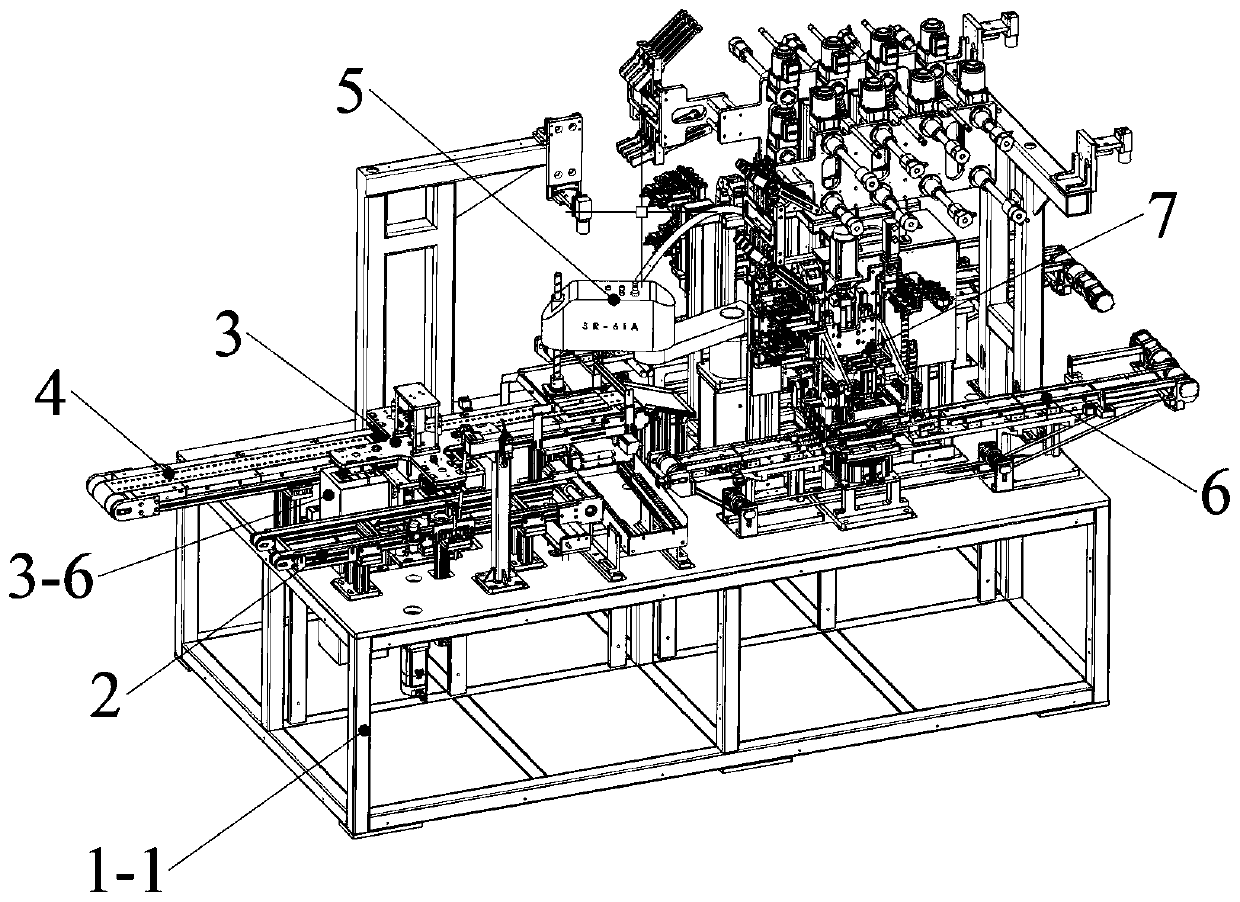

[0082] Such as figure 1 As shown, the present invention is used to produce "IBC solar cell strings". The structure of the IBC solar cell string is as follows figure 1 As shown, it includes six or twelve cells A and multiple welding ribbons B (when six cells are connected to form a battery string, the cells used are full-piece cells; twelve cells are connected to form a battery string , the cells used are half-cell cells). Each battery sheet A is arranged at equal intervals in turn. Two adjacent cells A are connected by a set of ribbons B. There are four welding ribbons B in one set, and they are arranged along the direction vertical to the arrangement of battery sheets. The two ends of the four welding ribbons B respectively cover the opposite edges of the two adjacent battery sheets A. Adjacent two groups of soldering strips are staggered; therefore, any battery shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com