Stair tread overlay and manufacturing process

a technology of overlays and stair treads, applied in the field of hardwood overlays, can solve the problems of increasing construction costs, increasing construction costs, and requiring extensive demolition to replace existing stairs, and achieve the effect of facilitating the installation of carpet type runners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

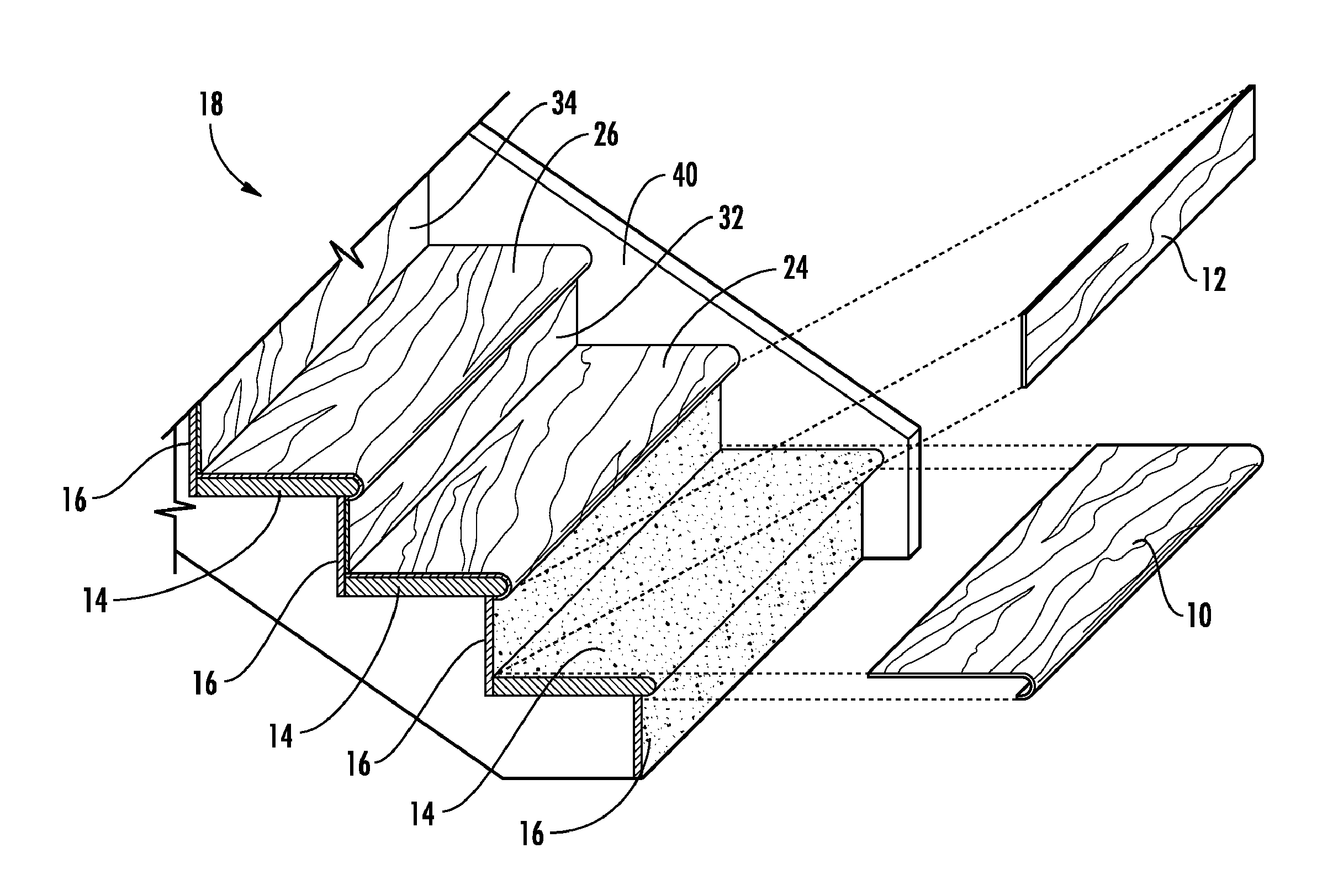

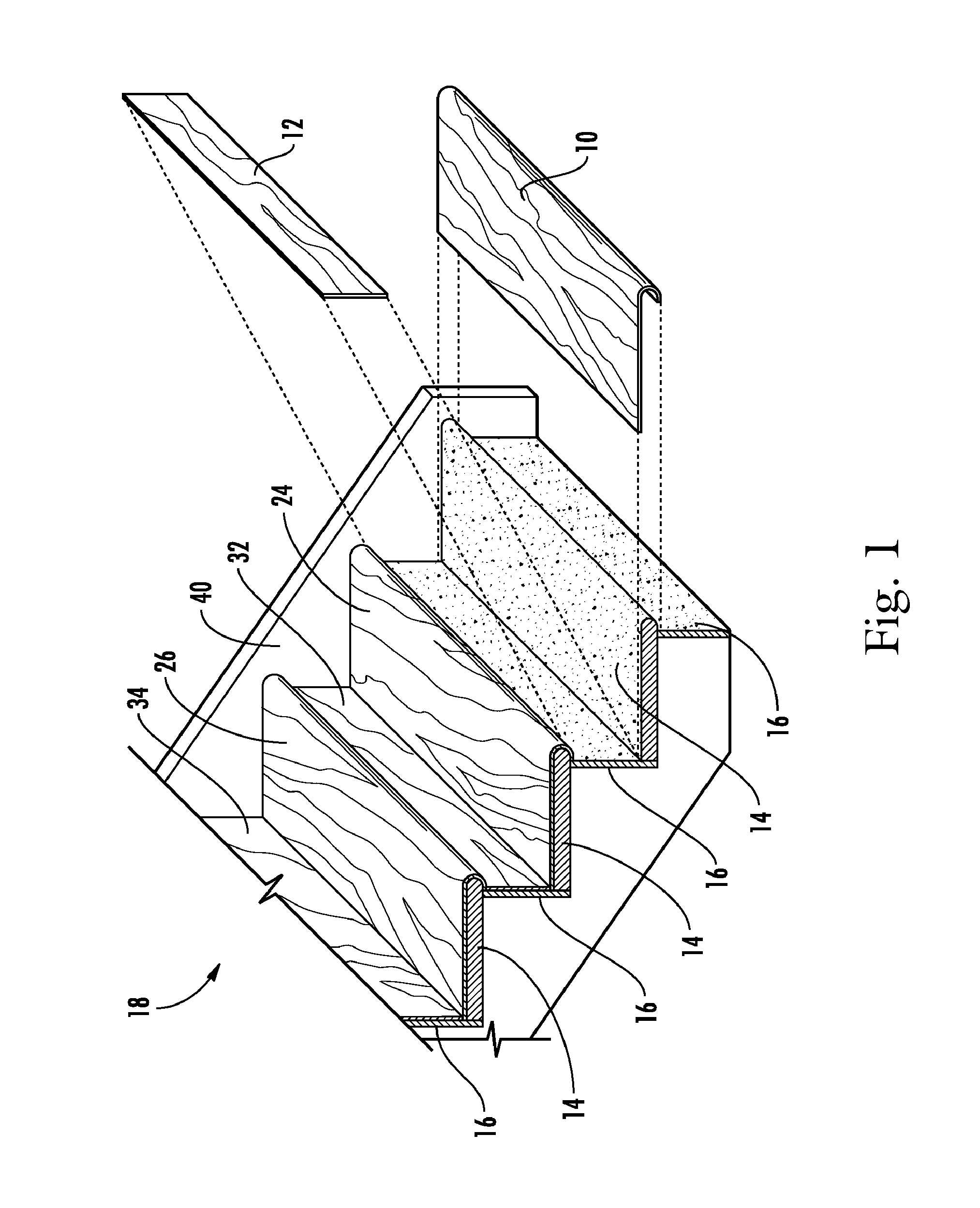

[0030]Referring to FIGS. 1-3, a stair tread overlay 10 and a riser overlay 12 for fitting over the treads 14 and risers 16 of a prefabricated composite or solid wood staircase 18 are shown. Both the tread overlay 10 and the riser overlay 12 are fabricated from solid oak, although it is contemplated that the tread overlay 10 and the riser overlay 12 can alternatively be fabricated from the wood of any non-monocot angiosperm tree (i.e., hardwood), including, but not limited to walnut, ash, cherry, and hickory. It is further contemplated that the tread overlay 10 and riser overlay 12 can be fabricated from the wood of any coniferous tree (i.e., softwood), including, but not limited to cedar, pine, and spruce, although hardwoods are generally preferred over softwoods for their superior durability.

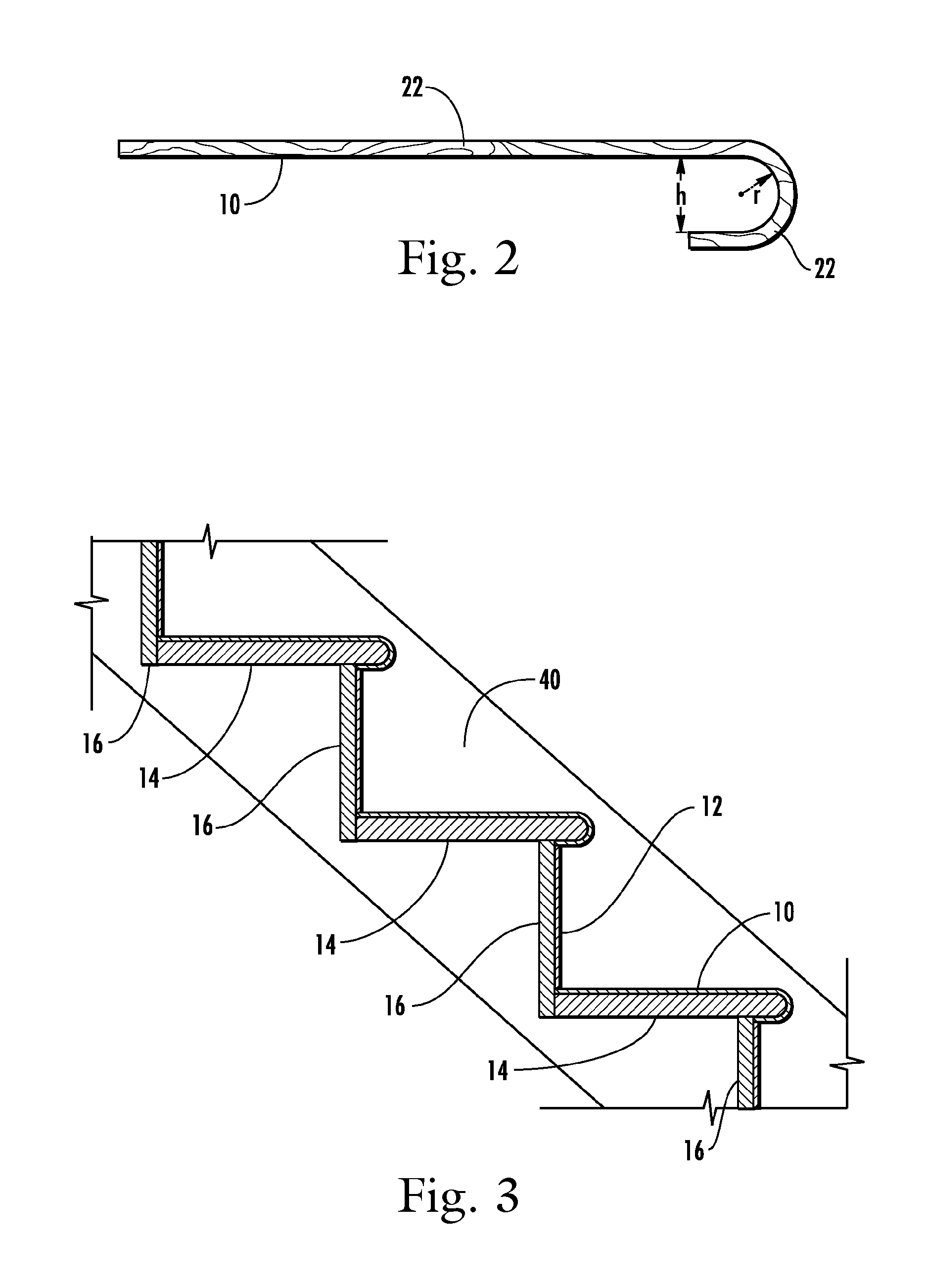

[0031]The tread overlay 10 is preferably milled from a solid piece of hardwood and is defined by a planar tread portion 20 (see FIG. 2) and a rounded nose portion 22, although it is contemplate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com