Transparent hydrophobic and oleophobic functional coating material and transparent hydrophobic and oleophobic functional coating layer formed thereby

A hydrophobic and oleophobic functional coating technology, applied in the field of coatings, can solve the problems of difficult coating preparation and weak bonding between substrates, and achieve the effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

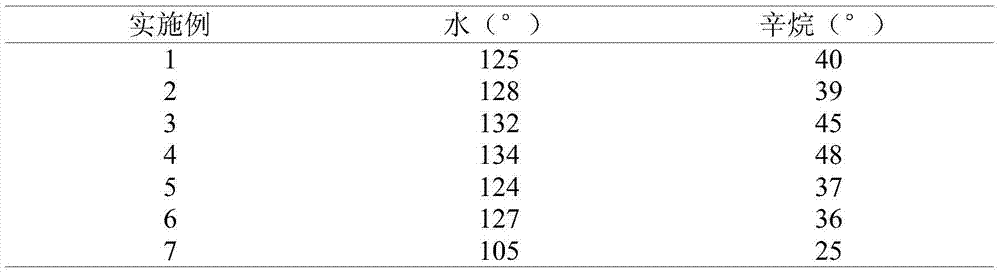

Examples

Embodiment 1

[0030] The fluorine-containing acrylic resin (10% fluorine content) is dissolved in butyl acetate to prepare a mass concentration of 5%. The silicon dioxide with a particle size of 10 nm was treated with an ethanol solution of tridecafluorooctyltrimethoxysilane, the hydrolysis time was 2 hours, and the silicon dioxide was centrifuged out, and dried in vacuum. The modified silicon dioxide is added to the resin solution with a concentration of 5% according to 1% of the weight of the resin, and after ultrasonication for 30 minutes, a uniform and transparent dispersion liquid is obtained. Clean the surface of the stainless steel sheet as the substrate, apply the dispersion to the surface of the stainless steel by the dip coating method, and dry the surface at 60°C after the surface is dry to obtain a hydrophobic and oleophobic coating film.

Embodiment 2

[0032] The fluorine-containing acrylic resin (30% fluorine content) is dissolved in toluene to prepare a mass concentration of 10%. The silicon dioxide with a particle size of 25nm was treated with tridecafluorooctyltriethoxysilane in isopropanol solution, the hydrolysis time was 2 hours, the silicon dioxide was centrifuged, and dried in vacuum. The modified silicon dioxide is added to the resin solution with a concentration of 10% according to 2% of the weight of the resin, and after ultrasonication for 40 minutes, a uniform and transparent dispersion liquid is obtained. Clean the surface of the stainless steel sheet as the substrate, apply the dispersion to the surface of the stainless steel by the dip coating method, and dry the surface at 60°C after the surface is dry to obtain a hydrophobic and oleophobic coating film.

Embodiment 3

[0034] Fluorocarbon resin (50% fluorine content) is dissolved in methyl ethyl ketone to prepare a mass concentration of 5%. The silicon dioxide with a particle diameter of 40nm was treated with n-butanol solution of heptadecafluorooctyltrimethoxysilane, the hydrolysis time was 2 hours, and the silicon dioxide was centrifuged out, and dried in vacuum. The modified silicon dioxide is added to the resin solution with a concentration of 5% according to 1% of the weight of the resin, and after ultrasonication for 30 minutes, a uniform and transparent dispersion liquid is obtained. The substrate polyimide (PI) plastic surface was cleaned, and the dispersion liquid was applied to the surface of PI by dip coating method. After the surface was dried, it was dried at 80°C to obtain a hydrophobic and oleophobic coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com