A method for preparing metal superhydrophobic biomimetic surface using ultrafast laser technology

An ultra-fast laser and super-hydrophobic technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of not considering the influence of super-hydrophobic performance, not combining drag reduction morphology, and not considering how to design super-hydrophobic bionic surfaces To achieve the effect of enhancing moisture-proof and anti-icing capabilities, reducing droplet retention, and improving drag reduction capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

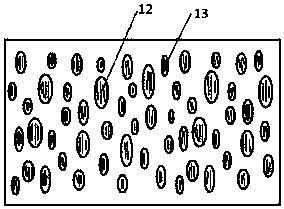

[0029] A specific embodiment of the method for preparing a metal superhydrophobic bionic surface using ultrafast laser technology in the present invention: a method for preparing a superhydrophobic micro-nano structure and a "groove" on an aluminum alloy using a femtosecond laser Drag reduction microstructure composite biomimetic surface method:

[0030] (1) Grind the aluminum alloy samples to be processed with different types of sandpaper in the order of small to large (400#, 800#, 2000#), and then use a polishing cloth to polish until the sample has a relatively bright metallic color;

[0031] (2) Clean the polished aluminum alloy sample in an ultrasonic cleaner filled with deionized water or alcohol solution for 30 minutes. After cleaning, dry the surface with cold air to obtain a clean aluminum alloy sample;

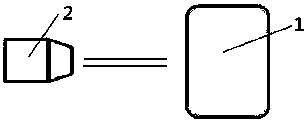

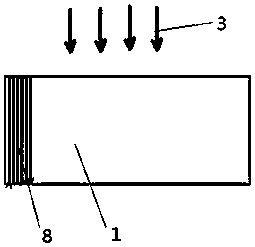

[0032] (3), such as figure 1 As shown, replace the femtosecond laser with a circular polarizing filter, perform laser-induced processing on the aluminum alloy samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com