A nanoparticle-polymer composite electret film, its preparation method and triboelectric nanogenerator containing the film

A high-molecular polymer and nanogenerator technology, applied in the direction of triboelectric generators, etc., can solve the problems of poor hydrophobicity and reduced electret performance of electret films, and achieve good transparency, high electret performance, and uniform surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

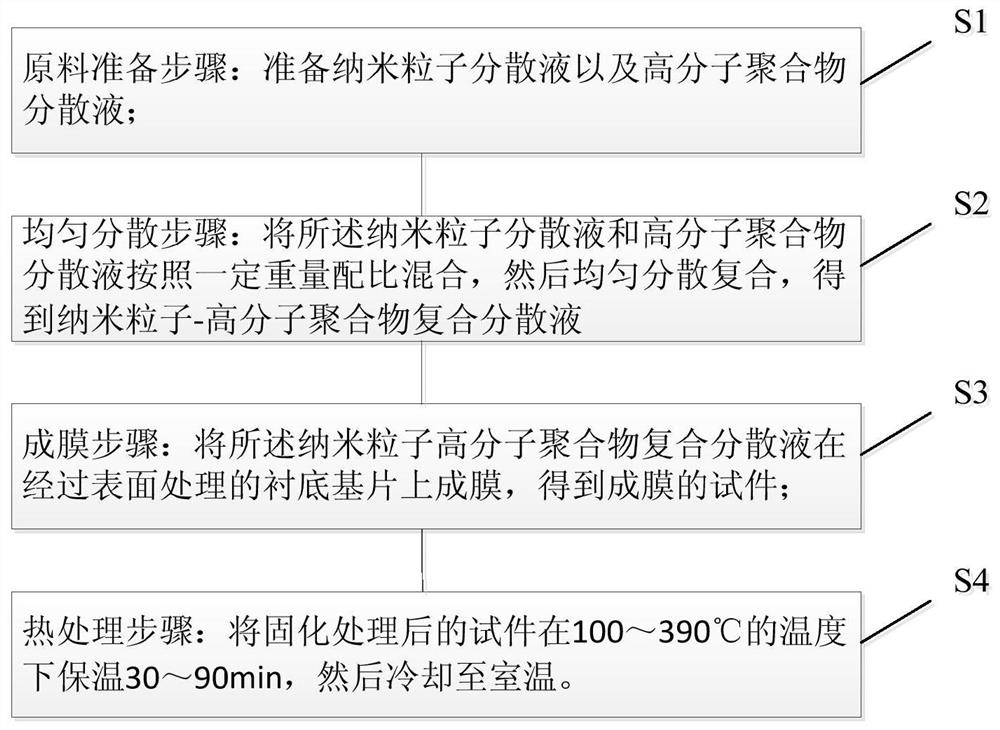

[0038] According to one aspect of the present invention, a method for preparing a nanoparticle-polymer composite electret film is provided. For the preparation process, see figure 1 , including the following steps:

[0039] S1, raw material preparation step: preparing nanoparticle dispersion liquid and polymer dispersion liquid;

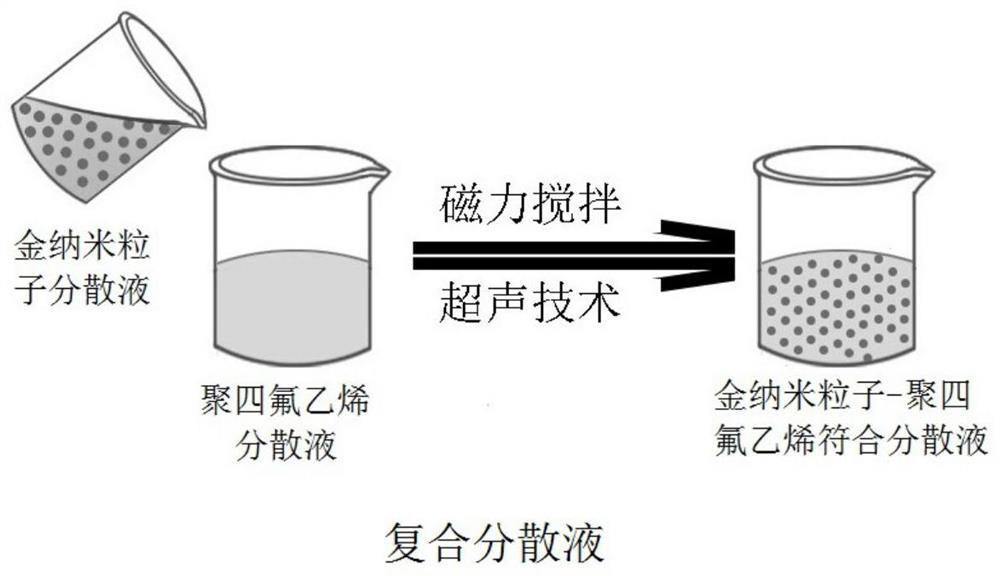

[0040] S2, uniform dispersion step: mixing the nanoparticle dispersion and the polymer dispersion according to a certain weight ratio, and then uniformly dispersing and recombining to obtain a nanoparticle-polymer composite dispersion; preferably, the nanoparticle dispersion and The polymer dispersion liquid is mixed according to the weight ratio of 1-30%:70-99%.

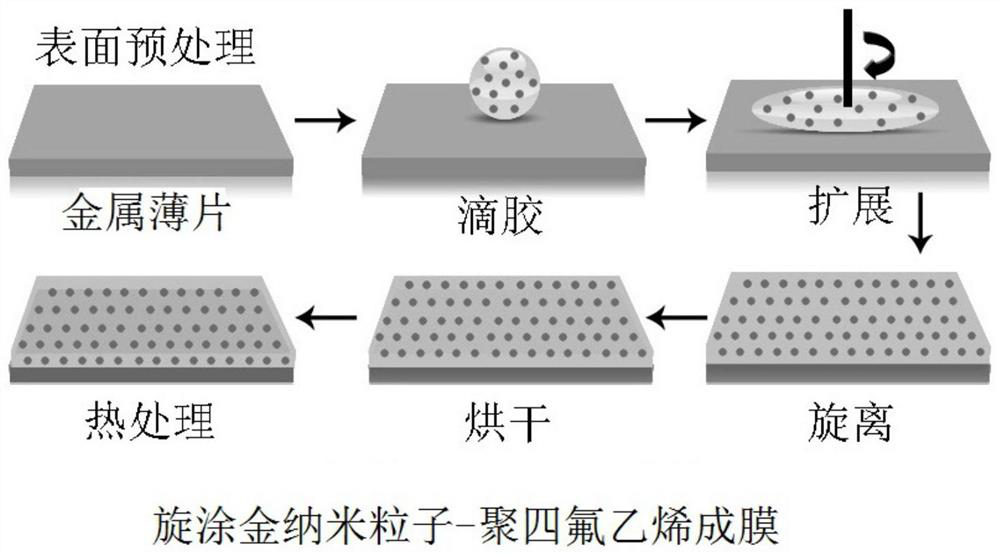

[0041] S3, film forming step: forming a film of the nanoparticle-polymer composite dispersion on the surface-treated substrate to obtain a film-forming specimen; the substrate can be any commonly used substrate, such as silicon sheet, glass, metal sheet, etc.;

[0042] Drying step: Dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com