Elastic handfeel paint

A hand-feeling and elastic technology, applied in the field of coatings, can solve the problems of waste of electricity and manpower, increase production costs, and long production time, and achieve the effects of reducing production costs, improving production efficiency, and reducing defective rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the examples, and the quantities in the examples are all percentages by weight.

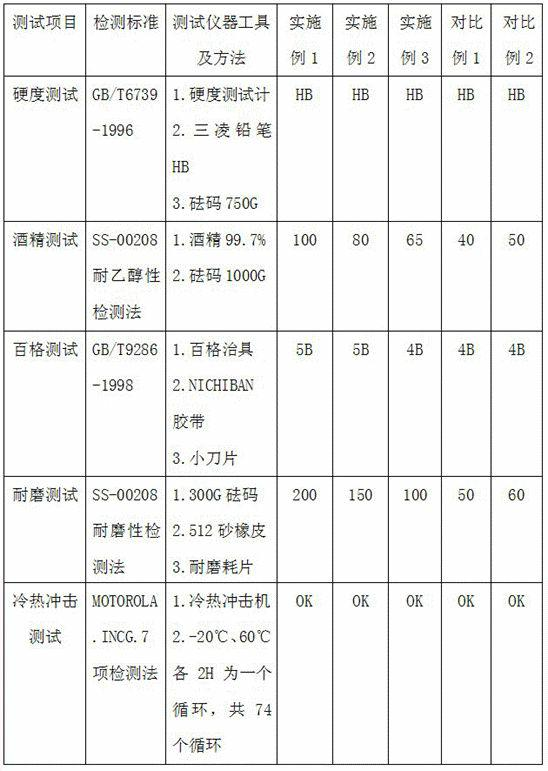

[0048] Table 1 is the ratio of each component in the hydroxyl component A and curing agent component B of Examples 1-3, Comparative Examples 1 and 2, wherein the leveling agent adopts a silicone leveling agent, and the matting powder adopts two Silica matting powder, the mixed solvent is composed of 30% ethyl acetate, 25% butyl acetate, 30% methyl isobutyl ketone, and 15% methyl diacetone alcohol.

[0049] Table 1

[0050] .

[0051] Wherein, the preparation method of hydroxyl component A is:

[0052] 1. Put hydroxyl-containing linear saturated polyester resin, nano-pigment, and polyurethane modified wetting and dispersing agent into a stainless steel solvent bucket, then use a dispersing mixer at 1200-1500 rpm, temperature 50°C-60°C, disperse for 45 minute;

[0053] 2. Add silica matting powder and mixed solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com