Super black flock oil wax sense polishing treatment agent for synthetic leather and preparation method thereof

A technology of synthetic leather and treatment agent, which is applied in fiber treatment, textile and papermaking, etc., to achieve the effect of increasing cost, good comprehensive effect and strong leather effect on leather surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

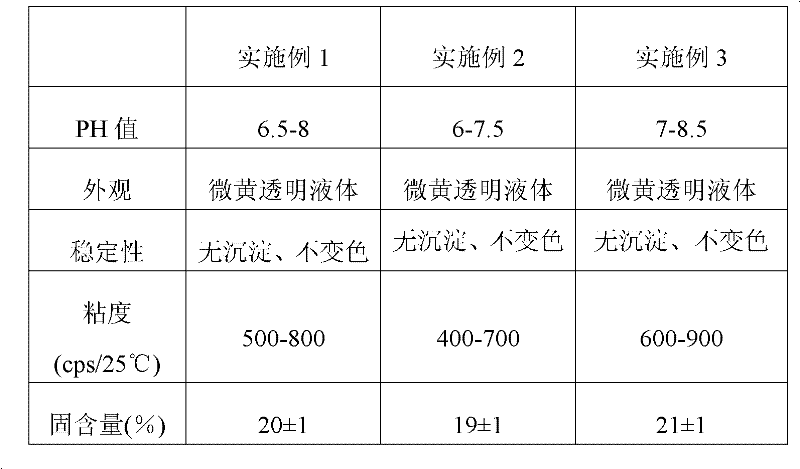

[0025] At normal temperature and pressure, put 10 parts by weight of nitrocellulose resin, 20 parts by weight of cyclohexanone, 20 parts by weight of butyl acetate, and 25 parts by weight of isopropanol into a 1L reactor, and filter after stirring at room temperature for 30 minutes; Add 4 parts by weight of silica matting powder, 1 part by weight of hydrophilic silicone oil, 2 parts by weight of castor oil, and 1 part by weight of erucamide to the mixture obtained in the previous step, and grind it for 20 minutes after uniform stirring at room temperature; Add 15 parts by weight of alkyd resin and 1 part by weight of silicone leveling agent to the mixture obtained in the first step, stir at room temperature for 30 minutes, and when the viscosity is stable, filter to obtain a special product for synthetic leather without precipitation and slightly yellowish transparent liquid. The finished product of black velvet oil waxy polishing treatment agent. The performance indexes of th...

Embodiment 2

[0028] At normal temperature and pressure, put 5 parts by weight of nitrocellulose resin, 20 parts by weight of cyclohexanone, 20 parts by weight of butyl acetate, and 10 parts by weight of isopropanol into a 1L reactor, and filter after stirring at room temperature for 30 minutes; Add 4 parts by weight of silica matting powder, 1 part by weight of hydrophilic silicone oil, 1 part by weight of castor oil, and 1 part by weight of erucamide to the mixture obtained in the previous step, and grind it for 20 minutes after uniform stirring at room temperature; Add 10 parts by weight of alkyd resin and 1 part by weight of silicone leveling agent to the mixture obtained in the first step, stir at room temperature for 30 minutes, and when the viscosity is stable, filter it to obtain a special product for synthetic leather without precipitation and slightly yellowish transparent liquid. The finished product of black velvet oil waxy polishing treatment agent. The performance indexes of t...

Embodiment 3

[0031] At normal temperature and pressure, put 10 parts by weight of nitrocellulose resin, 30 parts by weight of cyclohexanone, 30 parts by weight of butyl acetate, and 15 parts by weight of isopropanol into a 1L reactor, and filter after stirring at room temperature for 30 minutes; Add 5 parts by weight of silica matting powder, 2 parts by weight of hydrophilic silicone oil, 3 parts by weight of castor oil, and 2 parts by weight of erucamide in the mixture obtained in the previous step, and grind it for 20 minutes after uniform stirring at room temperature; Add 15 parts by weight of alkyd resin and 2 parts by weight of silicone leveling agent to the mixture obtained in the first step, stir at room temperature for 30 minutes, and when the viscosity is stable, filter to obtain a special product for synthetic leather without precipitation and slightly yellowish transparent liquid. The finished product of black velvet oil waxy polishing treatment agent. The performance indexes of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com