Porous adsorbent resin preparation method

An adsorption resin and pore type technology, applied in the field of synthetic polymer resins, can solve the problems of limited adsorption and desorption capacity of organic matter containing hydrogen bond acceptors, and achieve the effects of strong adsorption selectivity, strong adsorption force and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

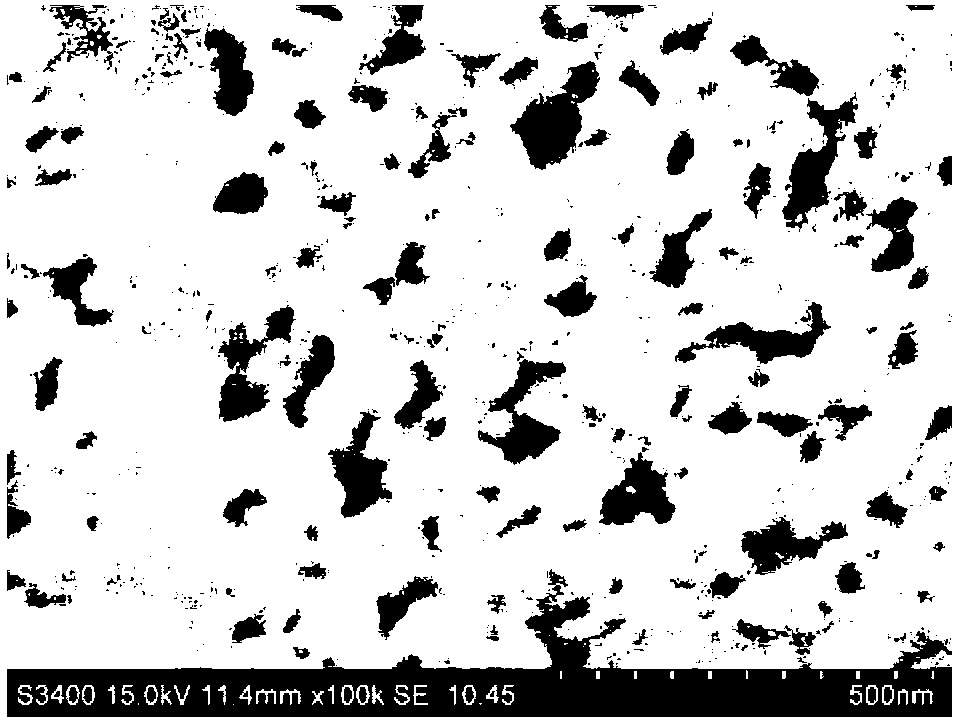

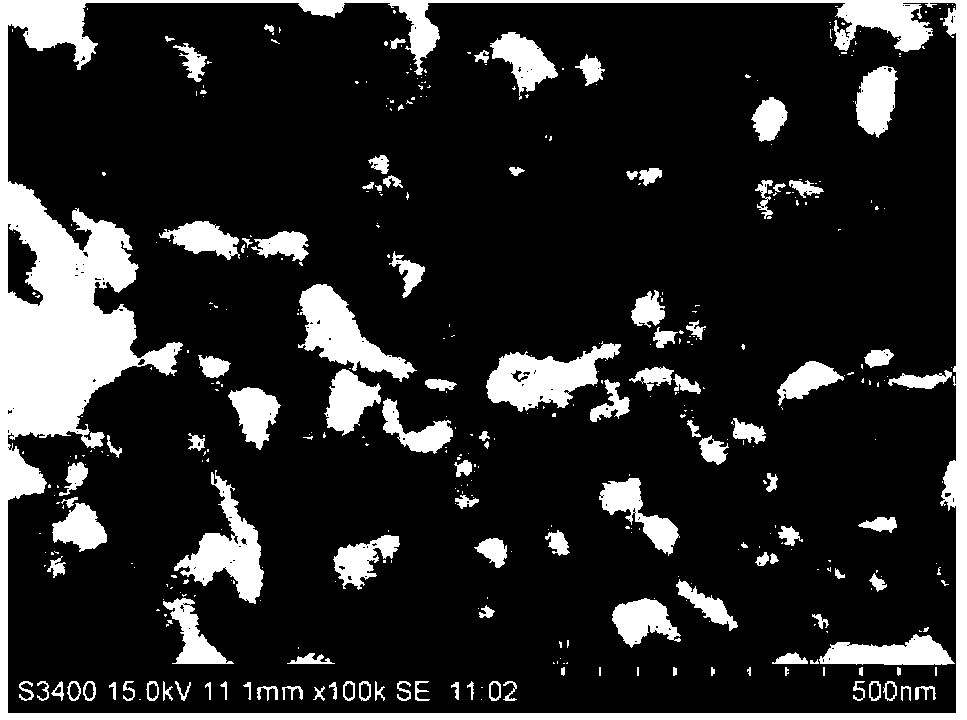

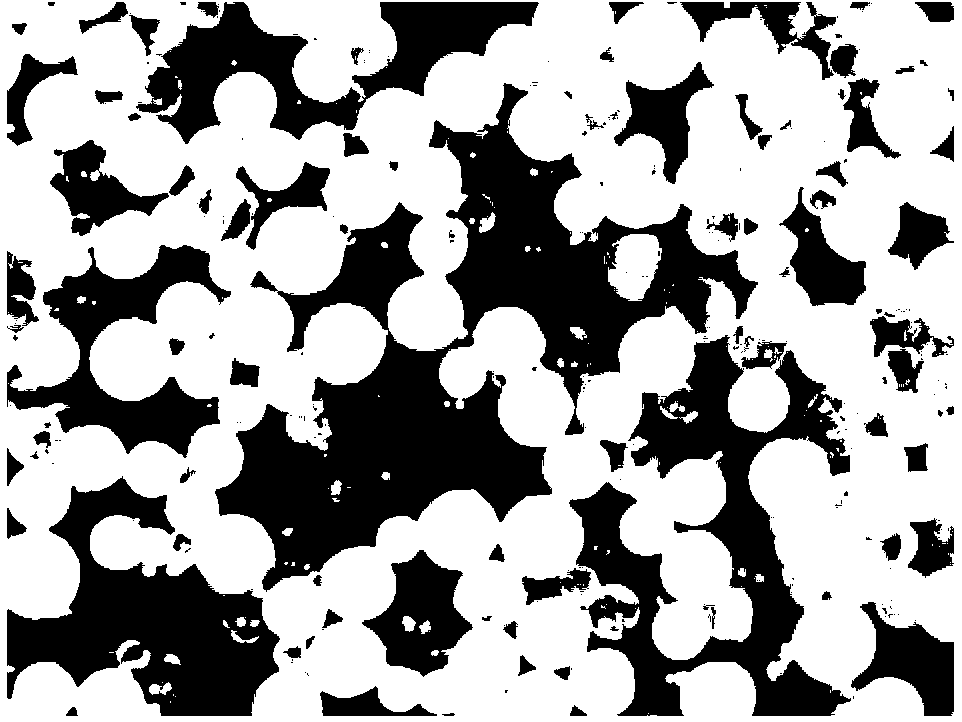

Image

Examples

preparation example Construction

[0024] A kind of preparation method of porous type adsorption resin, comprises the following steps:

[0025] Step 1. Add divinylbenzene, styrene, initiator (benzoyl peroxide or tert-butyl peroxide 2-ethylhexanoate), isobutyl acetate into the reaction kettle and mix thoroughly, add acrylic acid mono Phenol ester (p-phenol monoacrylate or p-phenol methacrylate) is fully mixed and stirred to obtain reactant I, wherein the mass of styrene accounts for 15% of the total mass of divinylbenzene, styrene and monophenol acrylate ~32%, the best ratio is 15%~28%, the mass of monophenol acrylate accounts for 3%~12% of the total mass of divinylbenzene, styrene and monophenol acrylate, and the best ratio is 4%~ 10%, the ratio of the mass of isobutyl acetate to the total mass of divinylbenzene, styrene and monophenol acrylate is 1:0.4~0.8, the optimal ratio is 1:0.4~0.6, the mass of the initiator and divinyl The ratio of the total mass of benzene, styrene and monophenol acrylate is 1 to 5:10...

Embodiment 1

[0036] 1. Add 81 parts of divinylbenzene, 15 parts of styrene, 2 parts of benzoyl peroxide and 125 parts of isobutyl acetate into the reaction kettle, stir for 20 minutes to fully dissolve, add p-phenol monoacrylate 4 portion, continue to stir for 30 minutes to fully dissolve.

[0037] 2. Heat 240 parts of deionized water to 75°C, add 2.5 parts of gelatin, 0.7 parts of hydroxymethyl cellulose, and 27 parts of sodium chloride, and stir for 30 minutes to fully dissolve.

[0038] 3. Add the reactant I to the reactant II under stirring, raise the temperature to 80°C, adjust the particle size of the oil phase by controlling the stirring speed, so that the particle size range is about 60 mesh, keep the reaction for 6 hours, and then raise the temperature to 90 ℃, reacted for 3 hours, then raised the temperature to 105 ℃, distilled isobutyl acetate until no oil was distilled, and obtained spherical particle resin.

[0039] 4. The obtained resin was washed with deionized water severa...

Embodiment 2

[0042] 1. Add 58 parts of divinylbenzene, 32 parts of styrene, 4 parts of benzoyl peroxide and 250 parts of isobutyl acetate into the reaction kettle, stir for 20 minutes to fully dissolve, add 10 parts of p-phenol monoacrylate portion, continue to stir for 30 minutes to fully dissolve.

[0043] 2. Heat 780 parts of deionized water to 75°C, add 3.3 parts of gelatin, 1.7 parts of hydroxymethyl cellulose, and 87.5 parts of sodium chloride, and stir for 30 minutes to fully dissolve.

[0044] 3. Add the reactant I to the reactant II under stirring, raise the temperature to 80°C, adjust the particle size of the oil phase by controlling the stirring speed, so that the particle size range is about 40 mesh, keep the reaction for 5 hours, and then raise the temperature to 90 ℃, reacted for 2 hours, then raised the temperature to 105 ℃, distilled isobutyl acetate until no oil was distilled, and obtained spherical particle resin.

[0045] 4. The obtained resin was washed with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com