High-temperature, high-humidity and high-salt mist-resistant polyurethane coating and preparation method thereof

A polyurethane coating and high temperature resistant technology, applied in the chemical field, can solve the problems of poor corrosion resistance of steel structures and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

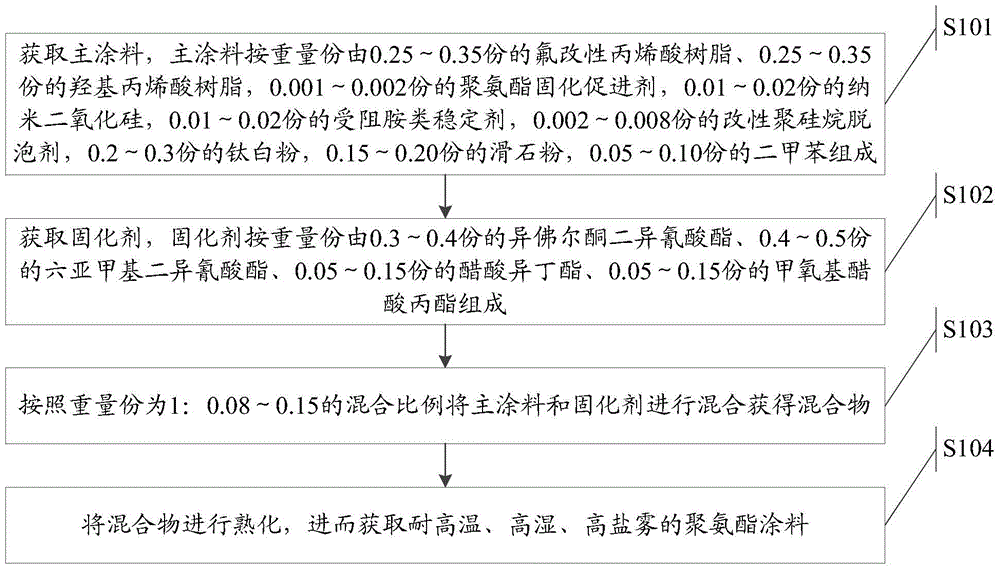

[0025] The invention provides a high-temperature, high-humidity, high-salt spray polyurethane coating and a manufacturing method to solve the technical problem of poor anticorrosion effect of steel structures in the prior art.

[0026] The general idea of the embodiment of the present invention is as follows:

[0027] Provide a high temperature resistant, high humidity, high salt spray polyurethane coating, characterized in that the polyurethane coating is composed of 1 part by weight of a main coating and 0.08 to 0.15 parts of a curing agent; It is stabilized by 0.25-0.35 parts of fluorine-modified acrylic resin, 0.25-0.35 parts of hydroxyl acrylic resin, 0.001-0.002 parts of polyurethane curing accelerator, 0.01-0.02 parts of nano-silica, and 0.01-0.02 parts of hindered amines Agent, 0.002~0.008 parts of modified polysilane defoaming agent, 0.2~0.3 parts of titanium dioxide, 0.15~0.20 parts of talcum powder, 0.05~0.10 parts of xylene; the curing agent consists of 0.3~0.3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com