Method for mass producing butyl acetate by reactive distillation method and using sulfuric acid as catalyst

A technology of butyl acetate and reactive distillation, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, carboxylate preparation, etc., can solve problems such as difficult to achieve, poor product quality, high cost of use, etc., to achieve corrosion Lightening, good separation effect, and the effect of solving corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

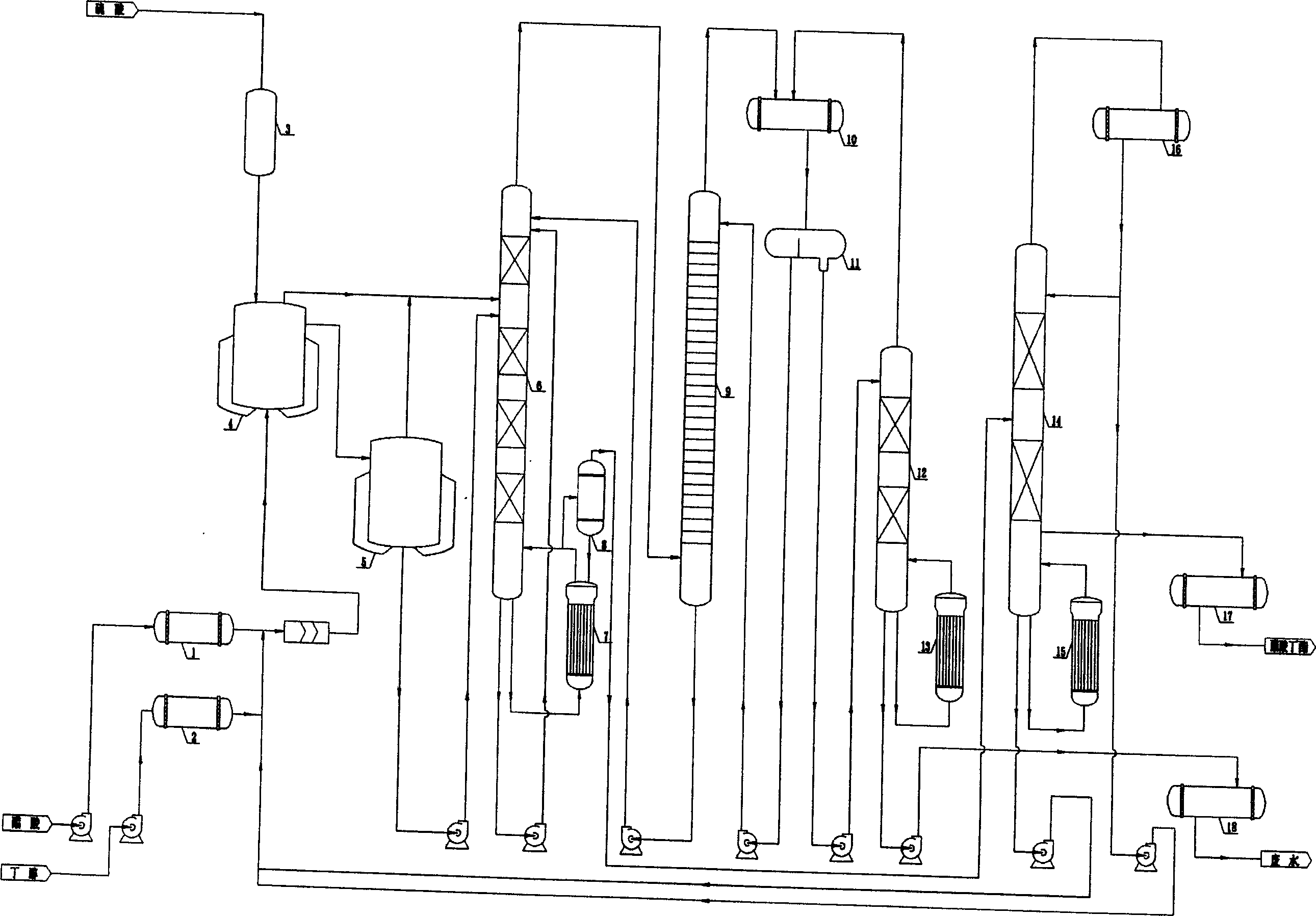

[0031] see figure 1, the whole production system is mainly composed of four towers, namely reactive distillation tower 6, azeotropic tower 9, recovery tower 12 and ester rectification tower 14. The reactive distillation column and the azeotropic column can be combined into one column, that is, the azeotropic column is placed above the reactive distillation column, which is a reactive distillation column in the classical sense. But in this case, the tower will be made very high, and corresponding auxiliary facilities need to be built to protect the tower and maintain its normal operation, which is not very economical. For this reason, the present invention divides the reactive distillation column in the classical sense into two columns—a reactive distillation column and an azeotropic column in practical applications. The specific embodiment of the present invention is as follows:

[0032] The raw material acetic acid is pumped into the acetic acid preheater 1 for preheating, ...

Embodiment 1

[0069] Acetic acid adopts the first-class product with a main content of about 99.5%, and the flow rate is 4.3T / h; n-butanol adopts the superior product with a content greater than 99.5%, and the flow rate is 5.4T / h; concentrated sulfuric acid adopts the superior product with a content greater than 98%. The flow rate is 0.05T / h.

[0070] The temperature of the acetic acid and butanol preheaters are both 108°C and the pressure is 155kPa, 1 # and 2 # The temperature of the pre-reactor is 110°C, the pressure is 150kPa; the top temperature of the reactive distillation tower is 100°C, the pressure is 130kPa, the bottom temperature is 130°C, and the pressure is 150kPa; The temperature at the bottom of the tower is 98°C and the pressure is 130kPa; the temperature at the top of the recovery tower is 98°C and the pressure is 100kPa; the temperature at the bottom of the tower is 103°C and the pressure is 120kPa; The discharge temperature of n-butyl acetate finished product is 126.5 DE...

Embodiment 2

[0072] The flow rate of raw material acetic acid is 4.0T / h, the flow rate of n-butanol is 5.0T / h, and other process conditions are all constant, and the content of n-butyl acetate in the 5 bottom initial esters of reactive distillation column is 98.3%, and the extraction The n-butyl acetate is 7.7T / h, the content of n-butyl acetate is 99.91%, and other indicators meet the requirements of superior products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com