Method for separating mixture of diisopropylamine and ethanol through azeotropic distillation

A diisopropylamine, azeotropic distillation technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve problems such as inability to separate, low relative volatility, difficult recovery of diisopropylamine raw materials, etc. Achieve the effect of convenient recycling, reduce secondary investment, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

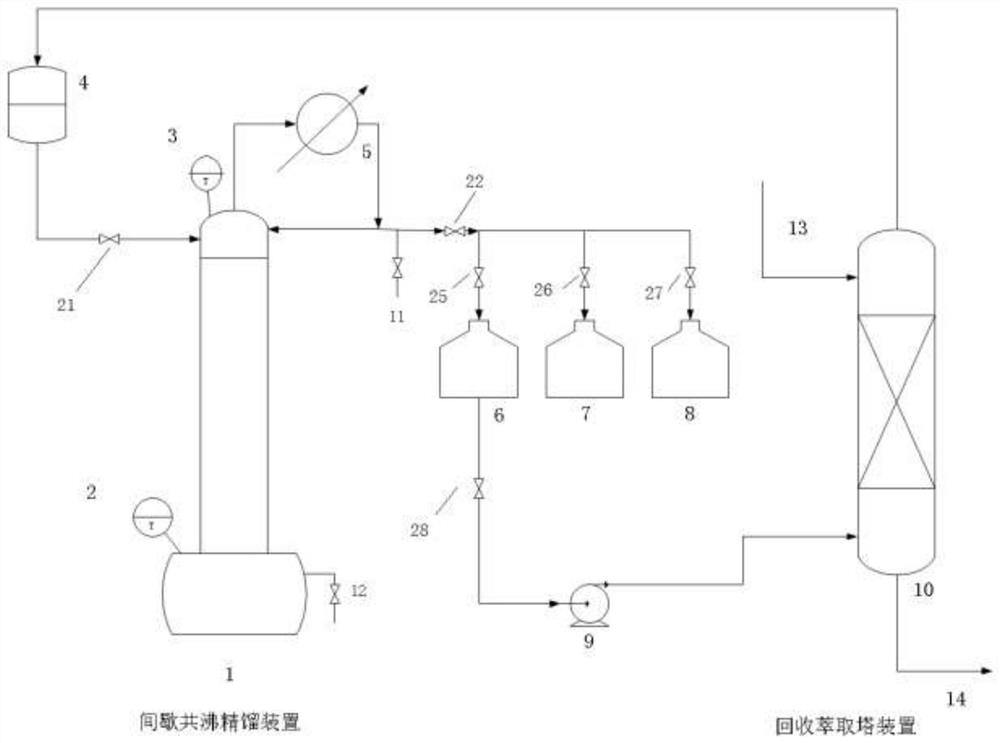

[0060] Example 1-1, a method for separating diisopropylamine and ethanol by azeotropic distillation, for the mixed solution I after water removal, the batch rectification process is adopted in the first case,

[0061] Device 1 is used, the shut-off valve 21 and the shut-off valve 28 are both closed, that is, the toluene tank 4 and the extraction tower 10 are not used in the embodiment 1-1.

[0062] details as follows:

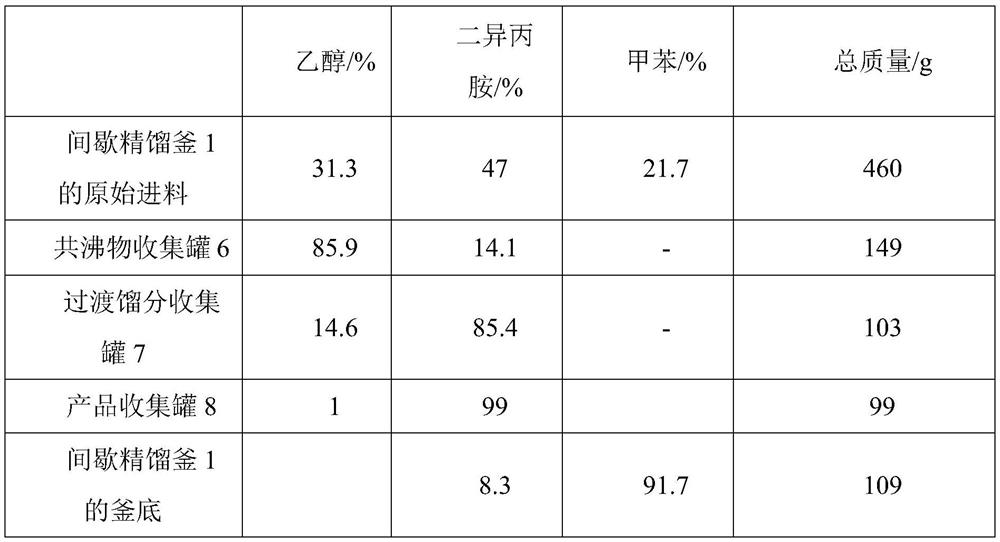

[0063] After 360g of water-removed mixed solution I was mixed with 100g of toluene as an entrainer, they were added together to the bottom of the batch rectification tank 1, and the total reflux until the temperature at the top of the tower was stable (that is, the displayed temperature at the temperature measuring point 3 on the top of the tower was 66~67℃), then start to extract the distillate, and then go to the azeotrope collection tank 6 after being condensed by the condenser 5. The volume ratio of collection tank 6=5:1); When the ethanol concentration dr...

Embodiment 1-2

[0071] Embodiment 1-2, the fraction collected in the excess fraction tank 7 and the next batch of mixed solution I after water removal are combined and rectified, as follows:

[0072] Mix the fraction 103g and 248g of the fraction collected in the transition fraction collection tank 7 obtained in Example 1-1 and 248g of the mixed solution I after water removal, and then add 109g of the bottom liquid of the batch distillation still 1 obtained in Example 1-1 to mix; The method described in above-mentioned embodiment 1-1 is carried out, and gained result is as follows table 2:

[0073] Table 2

[0074]

Embodiment 2

[0075] Example 2. The amount of toluene was changed from 100 g to 144 g, that is, the mass ratio of entrainer: mixed solution I after water removal = 0.4:1; the rest was the same as in Example 1-1. The final result is: about 120 g of 99% diisopropylamine is obtained, and the secondary recovery rate reaches 88.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com