A kind of hollow h-zsm-5 molecular sieve and preparation method and application

A molecular sieve and hollow technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of expensive template materials, difficult control of the pore-forming process, and low yield of final products. , achieve large industrial application prospects, solve the effect of low pore-forming yield and improve reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

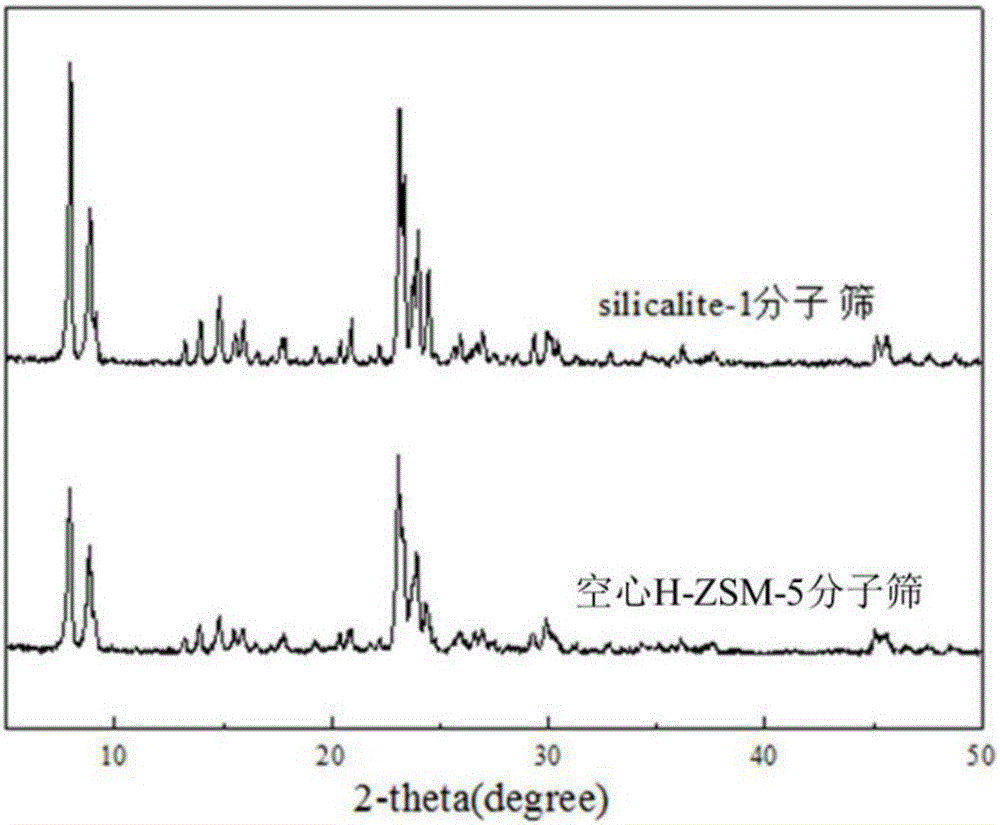

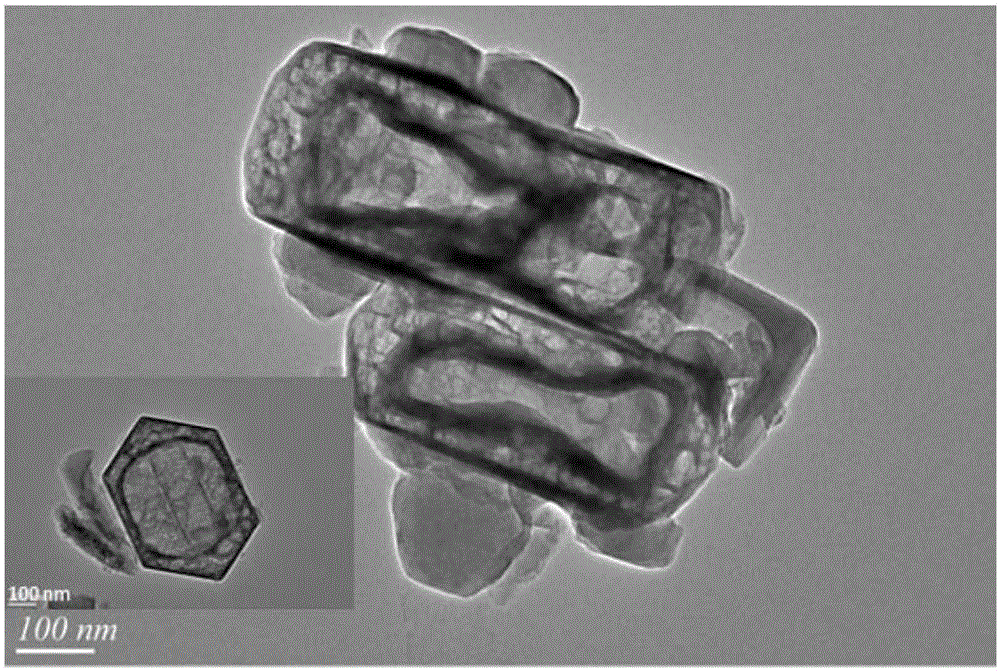

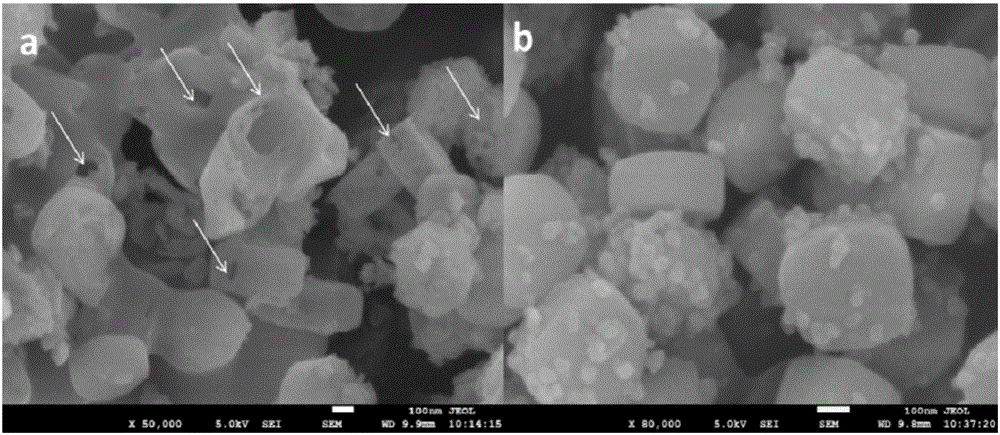

[0025](1) Synthesis of pure silicon molecular sieve silicalite-1:

[0026] Tetraethyl ammonium hydroxide (TPAOH) is used as the template, water and ethanol are used as the solvent, and TEOS is made of SiO 2 (1 mole of TEOS corresponds to 1 mole of SiO 2 ), the molar composition of each raw material is: 1SiO 2 :0.2TPAOH:5EtOH:50H 2 O. The various raw materials were stirred and mixed evenly at room temperature, and then transferred to a crystallization kettle for crystallization at 180°C for 3 days. After the obtained product was filtered, washed and dried, the powder was calcined in a muffle furnace at 550° C. for 6 hours to obtain a silicalite-1 molecular sieve with a grain size of 400 nm;

[0027] (2) Hollow Na-ZSM-5 molecular sieve synthesis:

[0028] With the silicalite-1 molecular sieve prepared in step 1 as silicon source, with NaAlO 2 As the aluminum source and the sodium source, the silicon source, the aluminum source and the sodium source are composed according t...

Embodiment 2

[0036] (1) in adjusting embodiment 1, each raw material molar composition is: 1SiO 2 :0.4TPAOH:10EtOH:5H 2 O The crystallization temperature of the synthesized silicalite-1 molecular sieve is 110°C, and the crystallization time is 8 days. After the obtained product is filtered, washed and dried, the powder is calcined in a muffle furnace at 450°C for 8 hours to obtain a silicalite-1 molecular sieve with a particle size of 300nm ;

[0037] (2) The silicalite-1 molecular sieve prepared in step 1 is used as silicon source, and Al(NO 3 ) 3 As the aluminum source, NaCl is used as the sodium source, and the silicon source, the aluminum source and the sodium source are composed according to the molar composition: SiO 2 :Al 2 o 3 :Na 2 O=1:0.005:0.01 is dissolved in a certain volume of 0.05mol / L TPAOH solution (the relationship between the volume of the TPAOH solution and the silicalite-1 molecular sieve is: each gram of silicalite-1 molecular sieve corresponds to 50ml of the TP...

Embodiment 3

[0041] (1) adjust each raw material molar composition in embodiment 1 to be: 1SiO 2 :0.05TPAOH:3EtOH:200H 2 O The crystallization temperature of the synthesized silicalite-1 molecular sieve is 150°C, and the crystallization time is 5 days. After the obtained product is filtered, washed and dried, the powder is calcined in a muffle furnace at 500°C for 7 hours to obtain a silicalite-1 molecular sieve with a particle size of 700nm ;

[0042] (2) With the silicalite-1 molecular sieve prepared in step 1 as the silicon source, with Al 2 (SO 4 ) 3 As the aluminum source, NaOH is used as the sodium source, and the silicon source, the aluminum source and the sodium source are composed according to the molar composition: SiO 2 :Al 2 o 3 :Na 2 O=1:0.05:0.25 dissolved in a certain volume of 1mol / L TPAOH solution (the relationship between the volume of the TPAOH solution and the silicalite-1 molecular sieve is: each gram of silicalite-1 molecular sieve corresponds to 25ml of the TP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com