Method of separating acetone-isopropanol-water by three-tower heat-integrated extraction distillation

A technology of extractive distillation and isopropanol, which is applied in chemical instruments and methods, separation/purification of carbonyl compounds, preparation of organic compounds, etc., can solve problems such as high energy consumption, complicated operation, and great impact on product quality, and achieve The effect of low energy consumption, high product purity and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

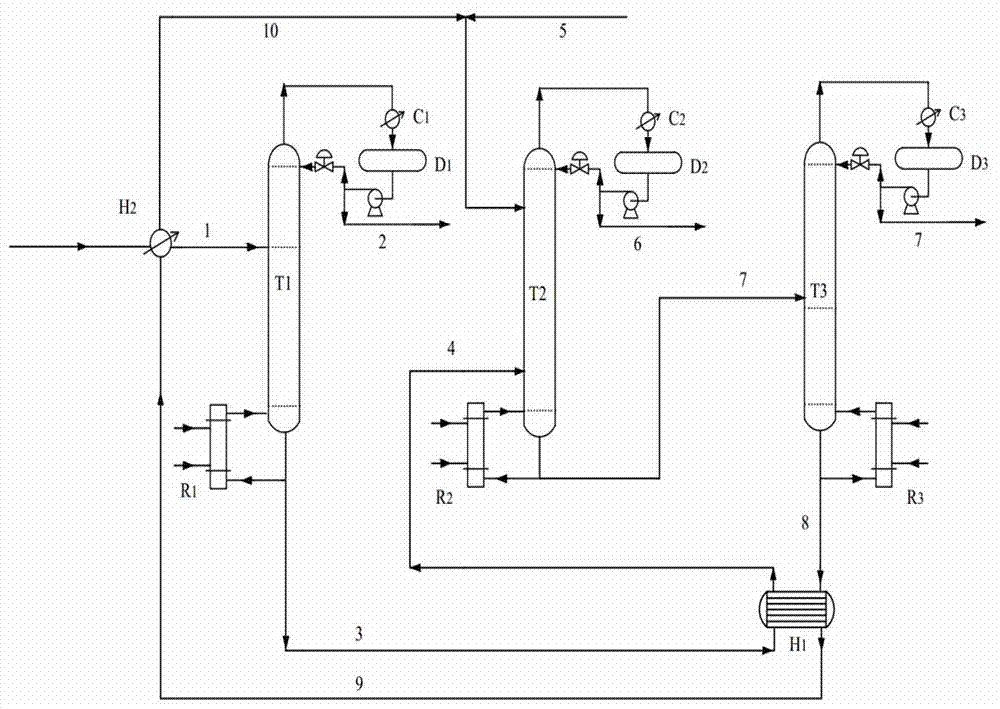

Embodiment 1

[0037] The feed temperature is 45° C., the flow rate is 1700 kg / h, and the pressure is 1 atm (absolute pressure). The feed contains 90% acetone, 5% isopropanol and 5% water. The operating pressure of the acetone column T1 is 1 atm (absolute pressure), the number of theoretical plates is 25, the feed plate of the fresh stream is 9, the reflux ratio is 2, the temperature at the top of the tower is 55.9°C, and the temperature at the bottom of the tower is 79.8°C; the operation of the isopropanol tower T2 is The pressure is 1atm (absolute pressure), the number of theoretical plates is 26, the material feed plate from the bottom of acetone column T1 is 18, the number of extractant feed plates is 5, the solvent ratio is 5:1, the reflux ratio is 1.5, and the top of the tower The temperature is 81.9°C, the temperature at the bottom of the tower is 145.8°C; the operating pressure of the solvent recovery tower T3 tower is 1 atm (absolute pressure), the number of theoretical plates is 14,...

Embodiment 2

[0039] The feed temperature is 45° C., the flow rate is 1800 kg / h, and the pressure is 1 atm (absolute pressure). The feed contains 93% acetone, 5% isopropanol, and 2% water. The operating pressure of the acetone column T1 is 1 atm (absolute pressure), the number of theoretical plates is 20, the feed plate of the fresh stream is 8, the reflux ratio is 1.8, the temperature at the top of the tower is 55.8°C, and the temperature at the bottom of the tower is 79.9°C; the operation of the isopropanol tower T2 is The pressure is 1atm (absolute pressure), the number of theoretical plates is 29, the material feed plate from the bottom of acetone column T1 is 20, the number of extraction agent feed plates is 6, the solvent ratio is 5:1, the reflux ratio is 2.3, and the top of the tower The temperature is 81.7°C, the temperature at the bottom of the tower is 145.9°C; the operating pressure of the solvent recovery tower T3 tower is 1 atm (absolute pressure), the number of theoretical plat...

Embodiment 3

[0041] The feed temperature is 45° C., the flow rate is 1750 kg / h, and the pressure is 1 atm (absolute pressure). The feed contains 95% acetone, 2% isopropanol, and 3% water. The operating pressure of the acetone column T1 is 1 atm (absolute pressure), the number of theoretical plates is 26, the feed plate of the fresh stream is 11, the reflux ratio is 2.1, the temperature at the top of the tower is 56.3°C, and the temperature at the bottom of the tower is 80.2°C; the operation of the isopropanol tower T2 is The pressure is 1atm (absolute pressure), the number of theoretical plates is 32, the material feed plate from the bottom of acetone column T1 is 22, the number of extraction agent feed plates is 8, the solvent ratio is 5:1, and the reflux ratio is 2.6. The temperature is 82.6°C, the temperature at the bottom of the tower is 146.3°C; the operating pressure of the solvent recovery tower T3 tower is 1 atm (absolute pressure), the number of theoretical plates is 17, the feed p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com