Method for preparing mesoporous chromium-based gaseous fluorinated catalyst

A phase fluorination catalyst and mesoporous technology, applied in the field of preparation of fluorination catalysts, can solve the problems of uneven distribution of catalyst active metals, high selectivity of by-product R115, uneven distribution of catalyst pore structure, etc. The effect of reducing energy consumption and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Under stirring at room temperature, 50g CrCl 3 ·6H 2 O, 10.2g AlCl 3 and 15mL of deionized water were dissolved in 95mL of absolute ethanol, and placed in a sealed autoclave for heat pretreatment at 96°C for 4 hours to obtain a highly dispersed salt solution.

[0043] Weigh 52g of SBA-16 white powder and place it in a flask, connect it to a vacuum pump, and keep it at a vacuum of 60kPa for 200min, add the above-mentioned highly dispersed salt solution into the flask dropwise, and keep the vacuum constant until the sample is dry. Take out the sample and put it in the tube furnace N 2 Calcined at 350°C for 3h in the atmosphere, and the precursor was obtained after natural cooling.

[0044] Weigh 4.05g CoCl 2 Dissolve in 120 mL deionized water, add the solution dropwise to the vacuum-treated precursor, then evaporate the liquid in a water bath, then dry it in an oven at 100 °C for 6 h, and finally heat it in a tube furnace at 340 °C under a nitrogen atmosphere. ℃ for ...

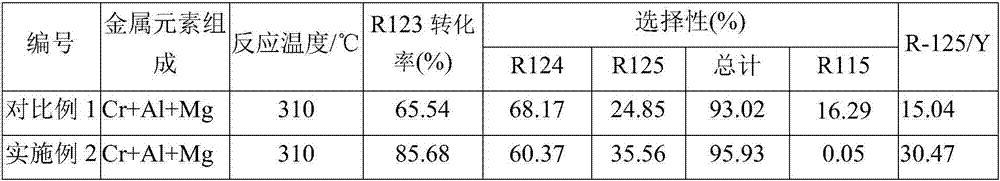

Embodiment 2

[0048] Under stirring at room temperature, 50g CrCl 3 ·6H 2 O, 6.8g AlCl 3 and 10 mL of deionized water were dissolved in 90 mL of absolute ethanol, and placed in a sealed autoclave for heat pretreatment at 98°C for 5 hours to obtain a highly dispersed salt solution.

[0049] Weigh 50g of SBA-16 white powder and place it in a flask, connect it to a vacuum pump, and keep it at a vacuum of 60kPa for 200min, add the above-mentioned highly dispersed salt solution into the flask dropwise, and keep the vacuum constant until the sample is dry. Take out the sample and put it in the tube furnace N 2 Calcined at 360°C for 5h in the atmosphere, and the precursor was obtained after natural cooling.

[0050] Weigh 6.38g MgCl 2 Dissolve in 120 mL deionized water, add the solution dropwise to the vacuum-treated precursor, then evaporate the liquid in a water bath, then dry it in an oven at 110 °C for 7 h, and finally heat it in a tube furnace at 330 °C under a nitrogen atmosphere. ℃ for...

Embodiment 3

[0054] Under stirring at room temperature, 50g CrCl 3 ·6H 2 O, 7.94g AlCl 3 and 20mL of deionized water were dissolved in 80mL of absolute ethanol, and placed in a sealed autoclave at 95°C for heat pretreatment for 4 hours to obtain a highly dispersed salt solution.

[0055] Weigh 50g of SBA-16 white powder and place it in a flask, connect it to a vacuum pump, and keep it at a vacuum of 60kPa for 200min, add the above-mentioned highly dispersed salt solution into the flask dropwise, and keep the vacuum constant until the sample is dry. Take out the sample and put it in the tube furnace N 2 Calcined at 350°C for 4h in the atmosphere, and the precursor was obtained after natural cooling.

[0056] Weigh 2.65g InCl 3 Dissolve in 120 mL deionized water, add the solution dropwise to the vacuum-treated precursor, then evaporate the liquid in a water bath, then dry it in an oven at 120 °C for 8 h, and finally heat it in a tube furnace at 350 °C under a nitrogen atmosphere. ℃ for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com