Method for separating n-hexane and acetone by liquid-liquid extraction-flash evaporation of ionic liquid

An ionic liquid, n-hexane technology, applied in extraction purification/separation, chemical instruments and methods, hydrocarbon purification/separation, etc., can solve the problem of high energy consumption, achieve high purity, easy recycling, and reduce separation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

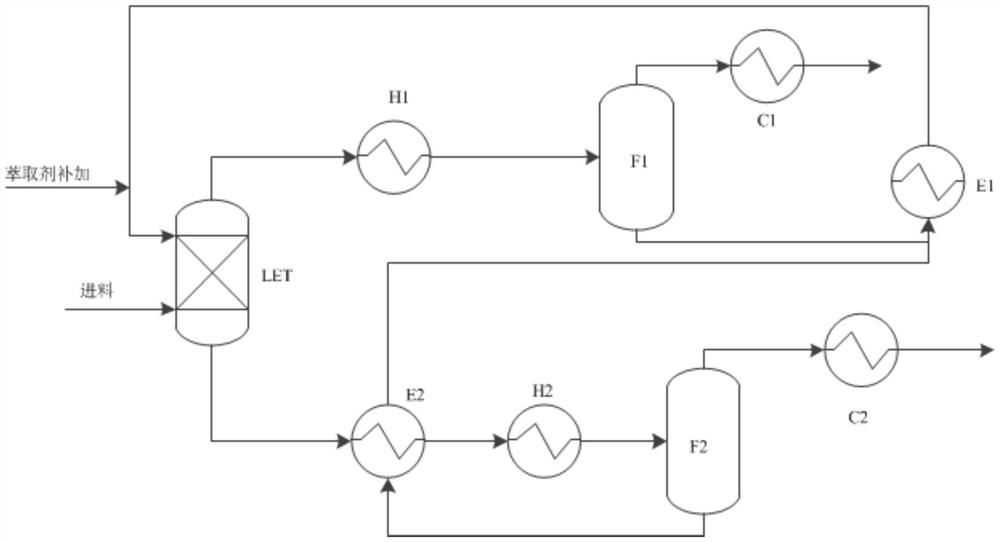

[0029] The feed flow rate is 140kg / h, the feed contains 52% acetone and 48% n-hexane (mass fraction), the number of theoretical plates in the liquid-liquid extraction tower (LET) is 5, and the mixture of acetone and n-hexane is extracted from the liquid-liquid extraction tower ( LET), the extractant enters from the top of the liquid-liquid extraction tower (LET), the extractant is 1-hexyl-3-methylimidazolium bis(trifluoromethanesulfonyl) salt ionic liquid, the flow rate is 280kg / h ( The feed flow mass ratio of the extractant to the acetone-n-hexane mixture was 2), and the temperature of the liquid-liquid extraction tower (LET) was 25°C. The operating pressure of the flash tank (F1) is 0.015 atm, the operating pressure of the flash tank (F2) is 0.01, the purity of acetone after separation is 99.95%, the yield is 99.95%, the purity of n-hexane is 99.95%, the yield 99.95%.

Embodiment 2

[0031] The feed flow rate is 140kg / h, and the feed contains 55% acetone and 45% (mass fraction) of n-hexane. The number of theoretical plates in the liquid-liquid extraction tower (LET) is 10. The mixture of acetone and n-hexane enters from the bottom of the liquid-liquid extraction tower (LET), and the extractant enters from the top of the liquid-liquid extraction tower (LET). The extraction agent is 1- Butyl-3-methylimidazolium trifluoromethanesulfonate ionic liquid, the flow rate is 70kg / h (the feed flow mass ratio of extractant to acetone-n-hexane mixture is 0.5), the liquid-liquid extraction tower (LET) The temperature is 35°C. The operating pressure of the flash tank (F1) is 0.01atm, the operating pressure of the flash tank (F2) is 0.02, the purity of acetone after separation is 99.97%, the yield is 99.97%, the purity of n-hexane is 99.97%, the yield 99.97%.

Embodiment 3

[0033] The feed flow rate is 140kg / h, and the feed contains 54% acetone and 46% (mass fraction) of n-hexane. The number of theoretical plates in the liquid-liquid extraction tower (LET) is 8. The mixture of acetone and n-hexane enters from the bottom of the liquid-liquid extraction tower (LET), and the extractant enters from the top of the liquid-liquid extraction tower (LET). The extraction agent is 1- Hexyl-3-methylimidazolium trifluoromethanesulfonate ionic liquid, the flow rate is 140kg / h (the feed flow mass ratio of extractant to acetone-n-hexane mixture is 1), and the temperature of the liquid-liquid extraction tower (LET) is 28°C. The operating pressure of the flash tank (F1) is 0.02atm, the operating pressure of the flash tank (F2) is 0.015, the purity of acetone after separation is 99.96%, the yield is 99.96%, the purity of n-hexane is 99.96%, the yield It is 99.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com