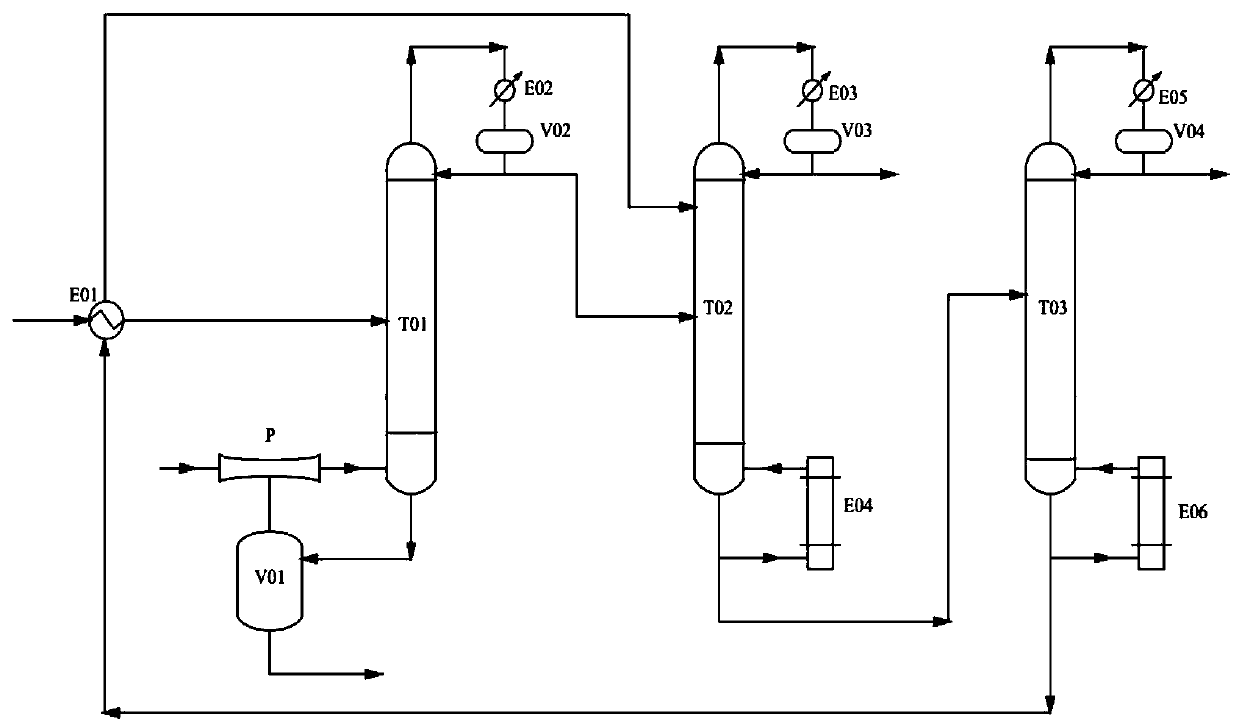

An energy-saving process for separating diethylamine-acetone wastewater by stripping-extractive distillation

A technology of extractive distillation and extractive distillation column, which is applied in the field of energy-saving technology for the separation of diethylamine-acetone wastewater by stripping-extractive distillation, and can solve the difficulty, reaction and process that cannot be separated by ordinary distillation and increase separation. Complicated problems, to achieve the effect of good chemical thermal stability, saving equipment investment, and improving relative volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The feed temperature is 20° C., the flow rate is 1000 kg / h, and the pressure is 1 atm absolute pressure. The feed contains 10% (mass fraction) of diethylamine, 20% (mass fraction) of acetone, and 70% (mass fraction) of water. The number of theoretical plates of the stripper is 20, the feed position of diethylamine-acetone wastewater is the 13th block, the theoretical plate number of the extractive distillation column is 25, and the feed position is the 15th block, the flow rate of the extraction agent ethylene glycol It is 600kg / h (solvent ratio is 0.6), the feeding position of the extractant is the third block; the number of theoretical plates of the extraction agent recovery tower is 15, and the feeding position is the eighth block. The purity of diethylamine after separation is 99.10% (mass fraction), the purity of acetone is 99.10% (mass fraction), the purity of water is 99.98% (mass fraction), utilize jet pump to save about 150kg / h of steam.

Embodiment 2

[0033] The feed temperature is 20° C., the flow rate is 1000 kg / h, and the pressure is 1 atm absolute pressure. The feed contains 30% (mass fraction) of diethylamine, 30% (mass fraction) of acetone, and 40% (mass fraction) of water. The theoretical plate number of the stripper is 35, the feed position of diethylamine-acetone wastewater is the 25th block, the theoretical plate number of the extractive distillation column is 50, and the feed position is the 30th block, the flow rate of the extraction agent ethylene glycol It is 3000kg / h (solvent ratio is 3), the feeding position of the extractant is the 10th block; the number of theoretical plates of the extraction agent recovery tower is 40, and the feeding position is the 25th block. The purity of diethylamine after separation is 99.30% (mass fraction), the purity of acetone is 99.30% (mass fraction), and the purity of water is 99.99% (mass fraction), utilize jet pump to save about 200kg / h of steam.

Embodiment 3

[0035]The feed temperature is 20° C., the flow rate is 1000 kg / h, and the pressure is 1 atm absolute pressure. The feed contains 50% (mass fraction) of diethylamine, 20% (mass fraction) of acetone, and 30% (mass fraction) of water. The number of theoretical plates of the stripper is 25, the feed position of diethylamine-acetone wastewater is the 14th block, the theoretical plate number of the extractive distillation column is 30, and the feed position is the 15th block, the flow rate of the extraction agent ethylene glycol It is 1200kg / h (solvent ratio is 1.2), the feeding position of the extractant is the fifth block; the number of theoretical plates of the extraction agent recovery tower is 20, and the feeding position is the eleventh block. The purity of diethylamine after separation is 99.15% (mass fraction), the purity of acetone is 99.13% (mass fraction), the purity of water is 99.98% (mass fraction), utilize jet pump to save about 130kg / h of steam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com