Electromagnetic sabot separation device for light-gas gun

An electromagnetic separation, light gas gun technology, applied in compressed air guns, weapons without explosives, weapon types, etc., can solve the problems of limited projectile speed range, shortened projectile flight time, limited container size, etc., to improve controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

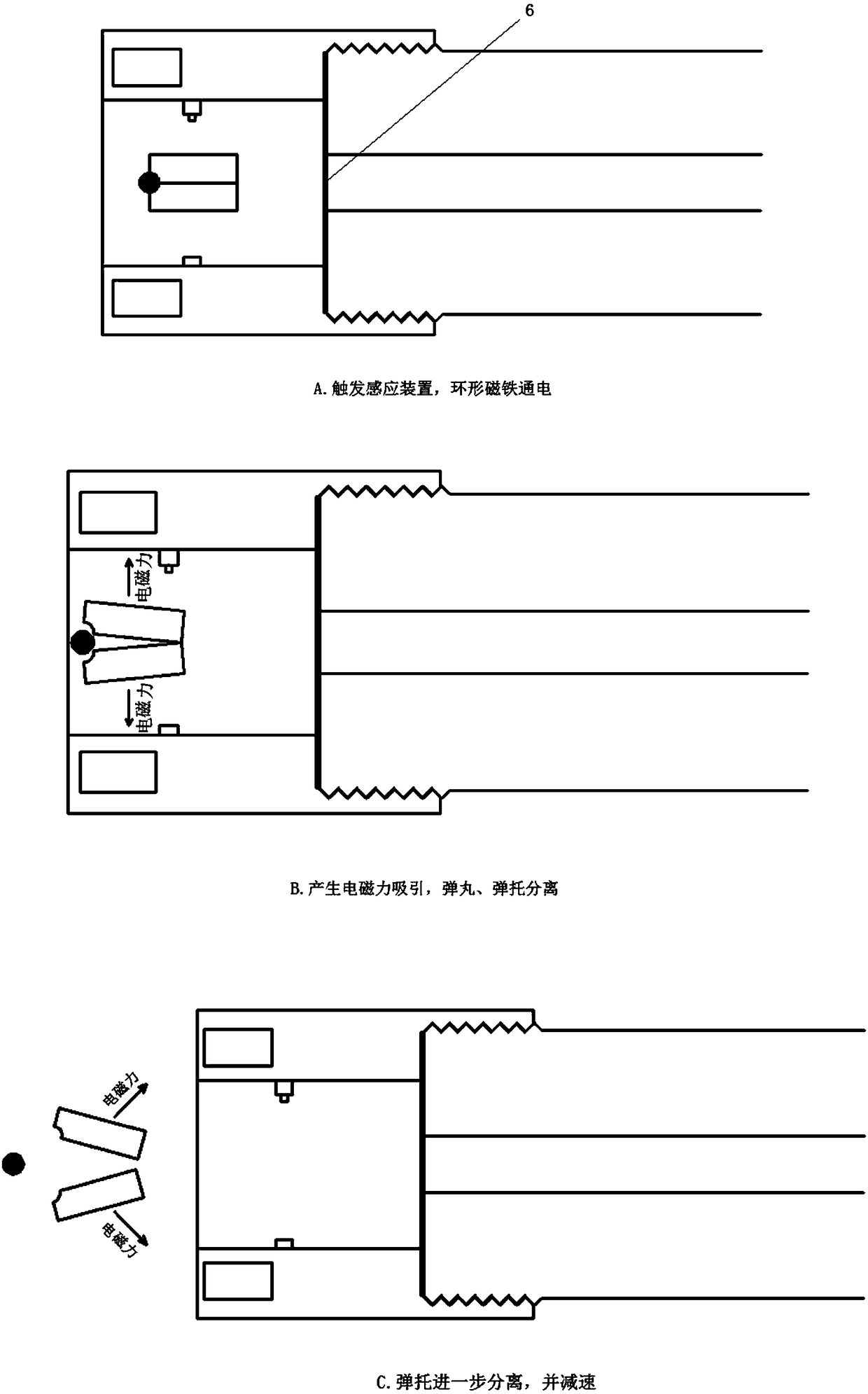

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

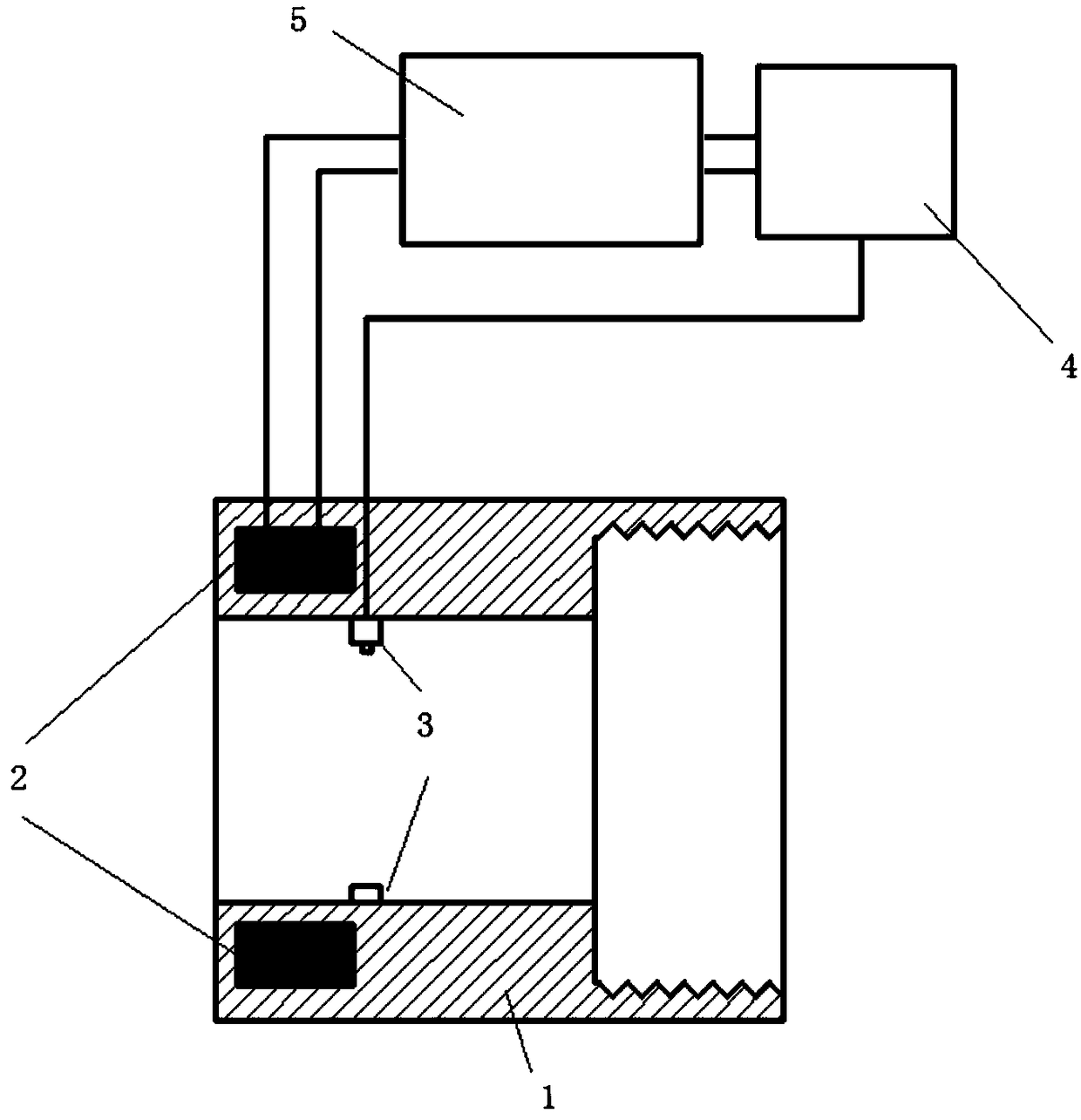

[0019] See attached figure 1 , an electromagnetic separation device for a light gas gun, comprising: an annular shell 1 with a set wall thickness, an annular electromagnet 2, an induction device 3, a controller 4, and a storage device 5;

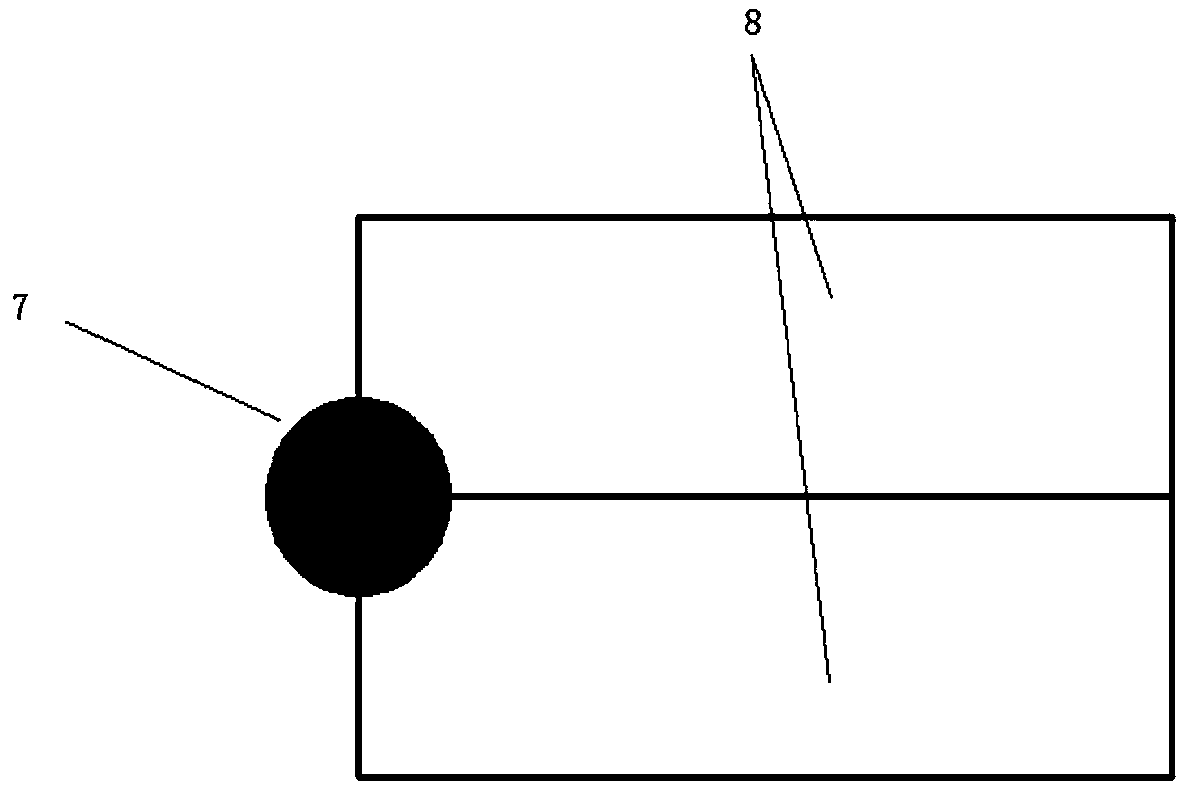

[0020] One end of the annular housing 1 is provided with a thread suitable for the muzzle of the light gas gun, and the annular housing 1 is threadedly connected with the muzzle 6 of the light gas gun at this end, so that the electromagnetic separation device is installed on the light gas gun. There are 6 muzzles; the other end of the annular housing 1 is provided with an annular electromagnet 2; the induction device 3 in this example adopts a laser trigger, and the laser trigger is installed on the inner peripheral surface of the annular housing 1 , located between the ring electromagnet 2 and the muzzle 6; the laser t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com