Method for extracting and separating n-heptane-dimethyl carbonate by ionic liquid

A technology of dimethyl carbonate and ionic liquid, which is applied in extraction and purification/separation, chemical instruments and methods, purification/separation of hydrocarbons, etc. It can solve the separation process of constant boiling agent n-heptane and dimethyl carbonate. , high energy consumption, inability to achieve effective separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

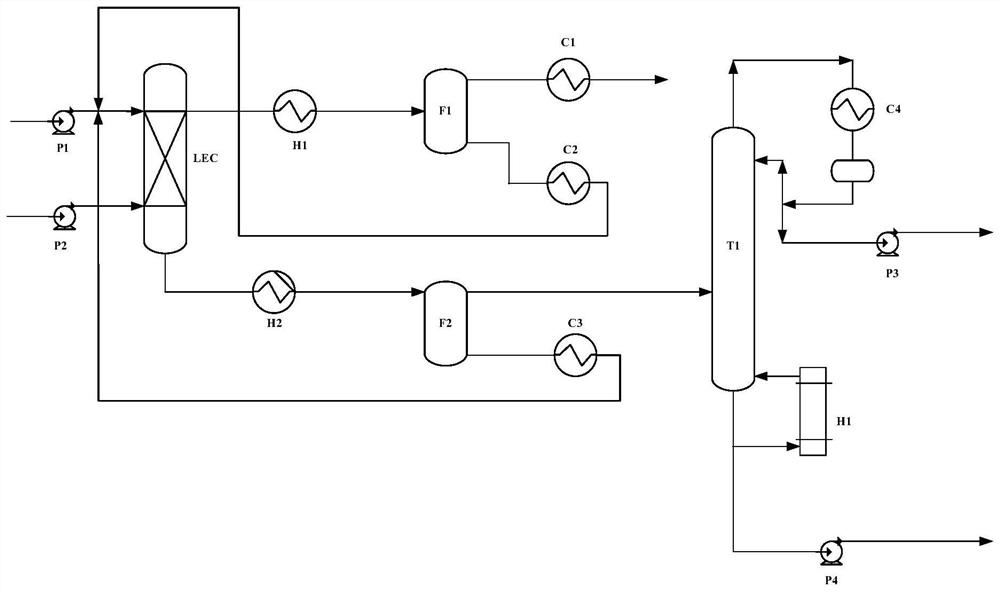

[0033] Feed flow rate is 100kg / h, contains n-heptane 10%, dimethyl carbonate 90% (mass fraction) in the feed, liquid-liquid extraction column (LEC) theoretical plate number is 7, n-heptane and dimethyl carbonate The ester mixture enters from the bottom of the liquid-liquid extraction column (LEC), and the ionic liquid enters from the top of the liquid-liquid extraction column (LEC). The extraction agent is 1-octyl-3-methylimidazole trifluoromethanesulfonate, and the flow rate is 70kg / h (the feed flow mass ratio of the ionic liquid to the n-heptane-dimethyl carbonate mixture is 0.7), and the temperature of the liquid-liquid extraction column (LEC) is 25°C. The operating pressure of the flash tank (F1) is 0.5 bar, the operating pressure of the flash tank (F2) is 0.5 bar, the purity of the separated dimethyl carbonate is more than 99.95%, and the yield is more than 99.95%.

Embodiment 2

[0035] The feed flow rate is 100kg / h, and the feed contains 30% of n-heptane and 70% (mass fraction) of dimethyl carbonate. The number of theoretical plates in the liquid-liquid extraction column (LEC) is 10. The mixture of n-heptane and dimethyl carbonate enters from the bottom of the liquid-liquid extraction column (LET), and the extractant enters from the top of the liquid-liquid extraction column (LEC). The agent is 3-methyl-1-octyl-1H-imidazole bis(2,2,2-trifluoroacetyl)imide ionic liquid, and the flow rate is 130kg / h (feed of extractant and phenol-water mixture The flow mass ratio is 1.3), and the temperature of the liquid-liquid extraction column (LEC) is 28.5°C. The operating pressure of the flash tank (F1) is 0.5 bar, the operating pressure of the flash tank (F2) is 0.5 bar, the purity of the separated dimethyl carbonate is 99.98%, and the yield is 99.98%.

Embodiment 3

[0037] The feed flow rate is 100kg / h, and the feed contains 60% of n-heptane and 40% (mass fraction) of dimethyl carbonate. The number of theoretical plates in the liquid-liquid extraction column (LEC) is 15. The mixture of n-heptane and dimethyl carbonate enters from the bottom of the liquid-liquid extraction column (LEC), and the extractant enters from the top of the liquid-liquid extraction column (LEC). The agent is 1-octyl-3-methylimidazolium hexafluorophosphate ionic liquid, the flow rate is 200kg / h (the feed flow mass ratio of extractant and phenol-water mixture is 2), the liquid-liquid extraction column (LEC) The temperature was 32°C. The operating pressure of the flash tank (F1) is 0.5 bar, the operating pressure of the flash tank (F2) is 0.5 bar, the purity of the separated dimethyl carbonate is 99.96%, and the yield is 99.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com