Production method of fenugreek gum

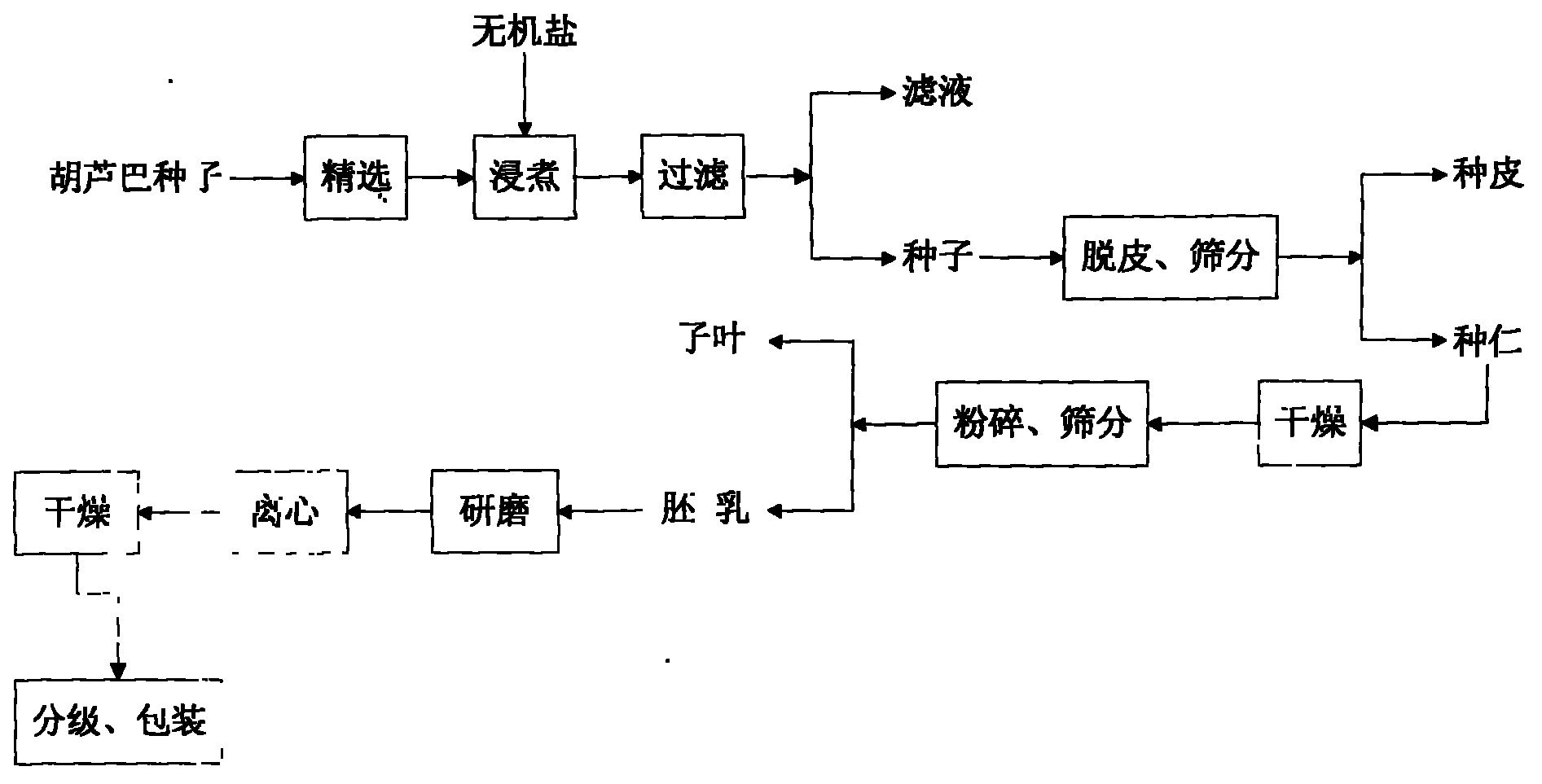

A production method, the technology of fenugreek gum, applied in the production field of fenugreek gum, can solve the problems of no competitive advantage, long time consumption, and many processes, and achieve the goal of improving comprehensive utilization, reducing production cost, and simplifying the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Take 0.5Kg of selected high-quality fenugreek seeds, put them in a 20L reaction kettle, and add 1% KNO 3 7.5L, soak at 95-105°C for 15 minutes, filter off the soaking liquid, send the boiled seeds to the peeling machine for peeling, and dry the kernels after peeling by airflow at a temperature of 95-105°C for 3- 10s, the moisture content is controlled at 10%-20%, through the crushing equipment and screening equipment, the cotyledon and endosperm are separated, the endosperm is placed in a grinder, 75% ethanol is ground at 1000r / min for 2 hours, centrifuged, and the rubber powder is dried , Graded packaging.

example 2

[0038] Get selected high-quality fenugreek seeds 0.5Kg, place in 20L reactor, add concentration and be 2% Mg(NO 3 ) 2 10L, soak at 95-105°C for 20 minutes, filter off the soaking liquid, send the boiled seeds to the peeling machine for peeling, and dry the kernels after peeling by airflow at a temperature of 95-105°C for 3-10s , the moisture content is controlled at 10%-20%, and the cotyledon and endosperm are separated through crushing equipment and screening equipment, and the endosperm is placed in a grinder, 85% ethanol is ground at 1500r / min for 3 hours, centrifuged, and the rubber powder is dried. Graded packaging.

example 3

[0040] Get selected high-quality fenugreek seeds 0.5Kg, place in 20L reaction kettle, add concentration and be 4% K 2 HPO 4 and KHCO 3 12.5L, soak at 95-105°C for 25 minutes, filter off the soaking liquid, send the boiled seeds to the peeling machine for peeling, and dry the kernels after peeling by airflow at a temperature of 95-105°C for 3- 10s, the moisture content is controlled at 10%-20%, through crushing equipment and screening equipment, the cotyledon and endosperm are separated, the endosperm is placed in a grinder, 95% ethanol is ground at 1500r / min for 4 hours, centrifuged, and the rubber powder is dried , Graded packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com