Method for separating benzene-n-propyl alcohol-water mixture through heat pump extractive distillation

An extractive distillation and extractive distillation tower technology, which is applied in the field of heat pump extractive distillation and separation of benzene-n-propanol-water mixtures, can solve the problems of waste of resources and high energy consumption, and achieves reduced loss, high purity, and chemical and thermal stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 100kmol / h of 30mol% benzene, 60mol% n-propanol and 10mol% n-propanol as an example:

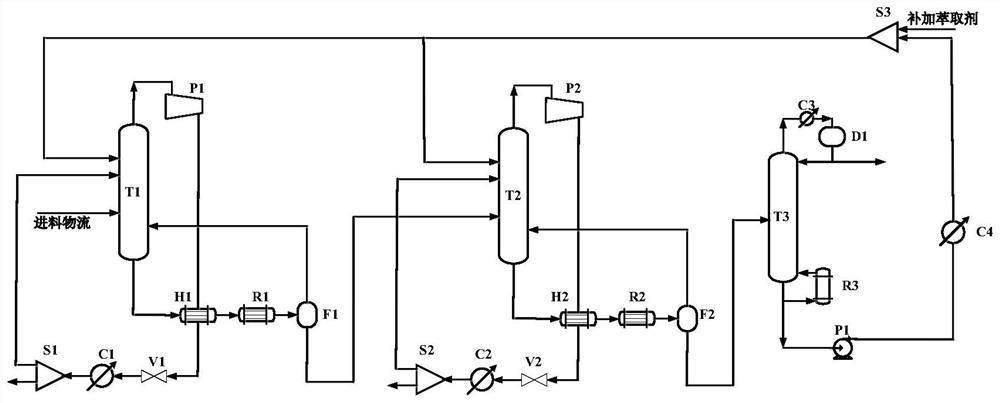

[0038]The number of plates of the extractive distillation column (T1) is 32, the mixed material enters the extractive distillation column (T1) from the 29th plate, and the extractant glycerin enters the extractive distillation column (T1) from the 3rd plate, and the extractant The flow rate is 35kmol / h, the bottom stream enters the flash tank (F1) after heat exchange with the overhead stream compressed by the heat exchanger (H1) and the heat pump compressor (P1), and the separated gas stream is sent from the first 32 trays are returned to the extractive distillation column (T1), and the liquid flow enters the extractive distillation column (T2) from the 43rd column, and the extractive distillation column (T2) has 48 trays in total, and the extractant glycerol is supplied from the 3rd column The plate enters the extractive distillation column (T2), and the flow rate of the extracta...

Embodiment 2

[0040] Take the 100kmol / h aqueous solution with 25mol% benzene and 15mol% n-propanol as an example:

[0041] The number of plates of the extractive distillation column (T1) is 30, the mixed material enters the extractive distillation column (T1) from the 25th plate, and the extractant glycerin enters the extractive distillation column (T1) from the 5th plate, and the extractant The flow rate is 30kmol / h, the bottom stream enters the flash tank (F1) after heat exchange with the overhead stream compressed by the heat exchanger (H1) and the heat pump compressor (P1), and the separated gas stream is sent from the first 30 trays are refluxed to the extractive distillation column (T1), and the liquid stream enters the extractive distillation column (T2) from the 45th column, and the extractive distillation column (T2) has 49 trays in total, and the extractant glycerol is supplied from the 7th column The plate enters the extractive distillation column (T2), and the flow rate of the e...

Embodiment 3

[0043] Take the 100kmol / h aqueous solution containing 35mol% benzene and 5mol% n-propanol as an example:

[0044] The number of plates of the extractive distillation column (T1) is 37, the mixed material enters the extractive distillation column (T1) from the 30th plate, and the extractant glycerin enters the extractive distillation column (T1) from the 5th plate, and the extractant The flow rate is 42kmol / h. The bottom stream enters the flash tank (F1) after heat exchange with the overhead stream compressed by the heat exchanger (H1) and the heat pump compressor (P1). 37 trays return to the extractive distillation column (T1), and the liquid flow enters the extractive distillation column (T2) from the 40th column, and the extractive distillation column (T2) has a total of 43 trays, and the extractant glycerol is supplied from the 3rd column The plate enters the extractive distillation column (T2), and the flow rate of the extractant is 21 kmol / h. The bottom stream enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com