Porous separator coated with organic/inorganic complex using aqueous coating solution, method for manufacturing same, and electrochemical device using same

A porous separator and complex technology, which is applied in the field of electrochemical devices and porous separators, can solve the problems of easy separation of inorganic particles, difficulty in improving processing speed, and increasing product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

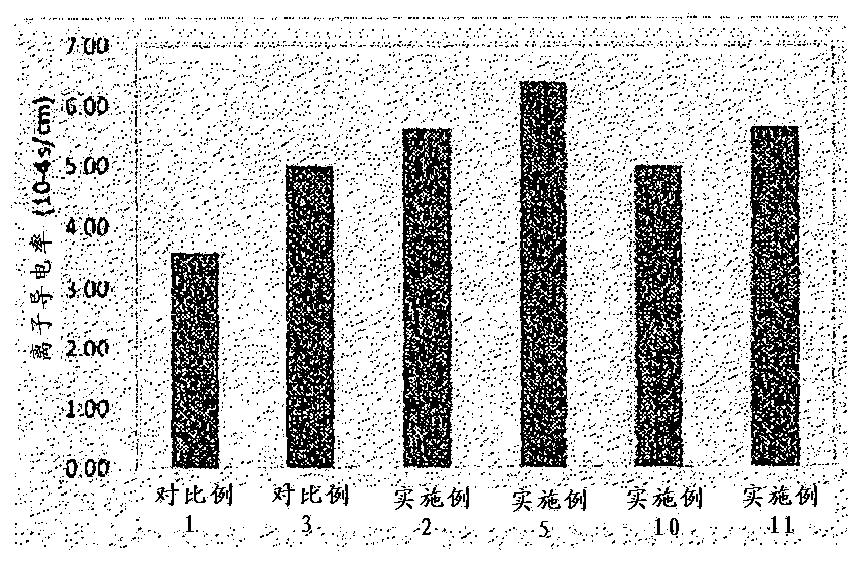

Examples

Embodiment Construction

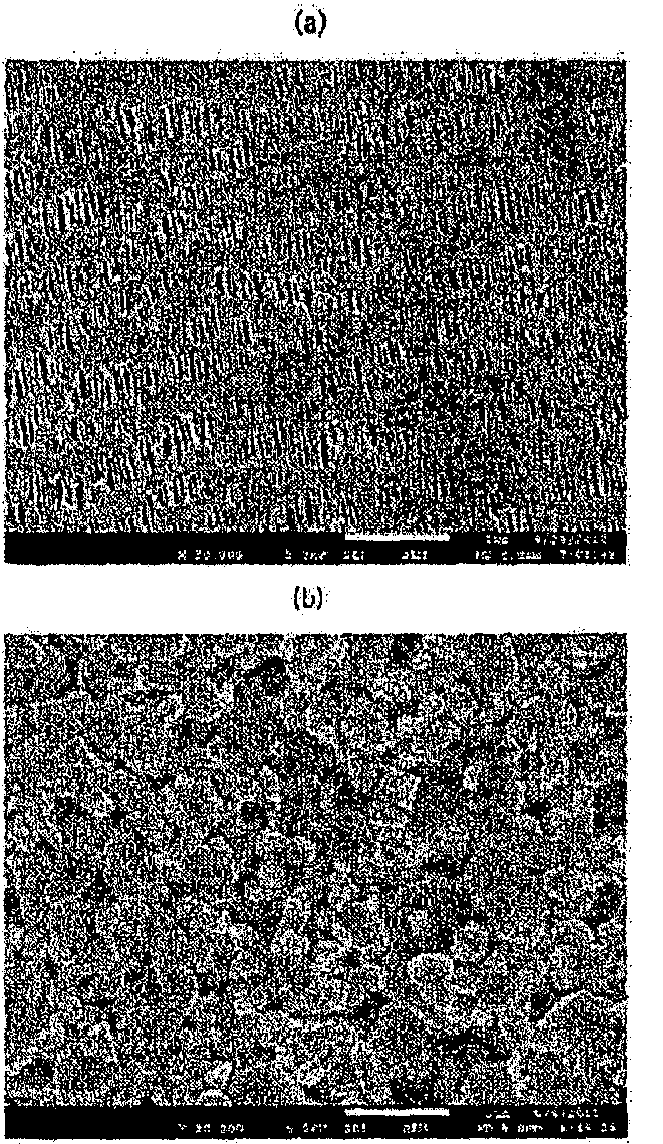

[0021] In the organic / inorganic complex-coated porous separator of the present invention, an aqueous coating solution in which inorganic particles and a polymer binder are dispersed in water is coated on at least one surface selected from the porous substrate and the porous substrate. on at least one area of at least a portion of the porous portion.

[0022]In the present invention, the porous substrate may use any porous substrate commonly used in electrochemical devices, such as lithium secondary batteries, and may include, for example, a thin film formed using one or more selected from the following or non- Woven fabrics: HDPE, LDPE, LLDPE, UHMWPE, PP, PET, PBT, POLYESTER, POLYESTER Acetal, polyamide, polycarbonate, polyimide, polyetheretherketone, polyethersulfone, polyphenylene ether, polyphenylene sulfide, polyethylene naphthalate, and the like.

[0023] Surface treatment techniques, such as corona, plasma, or high-energy radiation treatment, can be used to treat the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com