Hybrid electrode using silver nanowires and graphene, and preparation method thereof

A technology of mixed electrodes and silver nanowires, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, circuits, etc., can solve the problems of fluorine-doped tin oxide electrodes with rising prices, complicated procedures, and high prices, and achieve chemical Excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Preparation method of mixed electrode

[0035]The invention provides a method for preparing a mixed electrode. The method for preparing the mixed electrode includes: a step of coating silver nanowires on a substrate; and a step of coating solution-type graphene on the substrate coated with the above-mentioned silver nanowires .

[0036] Moreover, according to another embodiment of the present invention, a method for preparing a mixed electrode is provided, and the method for preparing the above-mentioned mixed electrode includes: a step of coating silver nanowires on a substrate; a step of applying dissolved graphene oxide; and a step of reducing the above-mentioned graphene oxide.

[0037] Wherein, the above-mentioned substrate is not limited as long as it is a transparent and flexible material. In particular, the above-mentioned substrate is preferably selected from polyethylene terephthalate (PET), polyethersulfone (PES), polymethylmethacrylate, etc. One or more of...

preparation example

[0048] (1) Preparation of silver nanowires

[0049] As a method introduced in ACS Nano (American Chemical Society Nano, 2010, 4(5), 2955)), polyols were used to adjust the diameter and length, thereby synthesizing silver nanowires.

[0050] Specifically, 6.010 mmol of polyvinylpyrrolidone (PVP) and 84.032 mmol of potassium bromide (KBr) were put into a round-bottomed flask filled with 20 mL of ethylene glycol (EG), and synthesized.

[0051] For thermal stabilization, after heating the mixture at a temperature of 170° C. for one hour while stirring at 800 rpm (revolutions per minute), 0.349 mmol of AgCl powder was added, thereby generating primary Ag crystals (seeds). Five minutes later, a 1.295 mmol silver nitrate solution in ethylene glycol was titrated at 1 mL / min for ten minutes, and the silver nanowires were completely grown over 1 hour.

[0052] The mixture was cooled briefly to about 5°C and maintained at room temperature for 50 minutes. The resultant was purified by...

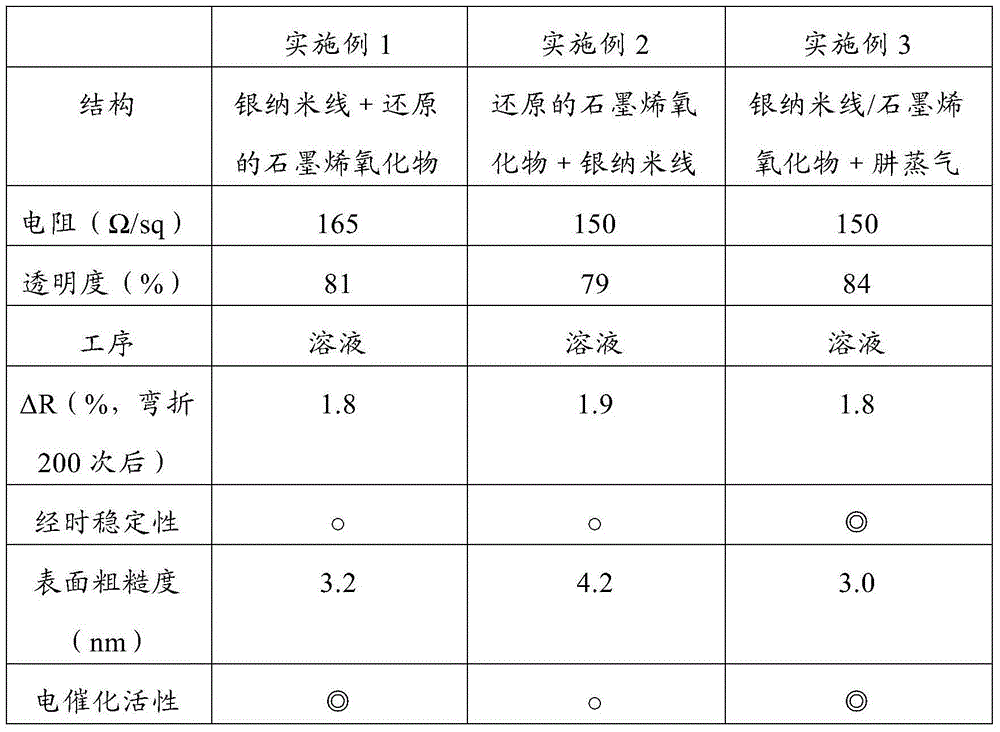

Embodiment 1

[0073] The reduced graphene solution was coated on the silver nanowire network to prepare the hybrid electrode.

[0074]Specifically, a silver nanowire solution with a diameter of about 35 nm and a length of about 30 μm was coated on a polyethylene terephthalate (PET) substrate by using a Meyor rod, and the silver nanowire The film is dried. Graphene oxide is reduced to graphene by immersing it in a hydrazine solution. The reduced graphene solution was spin-coated on the silver nanowire mesh at a speed of 1000 rpm. The thickness of the overcoated graphene film can be changed by adjusting the rotation speed. When the rotation speed is 1000rpm, the surface resistance reaches 165Ω / sq, and the light transmittance reaches 81%.

[0075] In silver nanowires having a network structure crossing each other, the nanowires cannot cover a part of the area of the substrate, thus forming an "uncovered area" with non-conductive properties. Covering the graphene sheet in a region that ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com