Dynamic-temperature-field preparation method for large-size C-axis sapphire crystal

A sapphire crystal, dynamic temperature technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of crystal quality reduction, growth stripes, etc., and achieve the effect of low defect probability and high crystal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

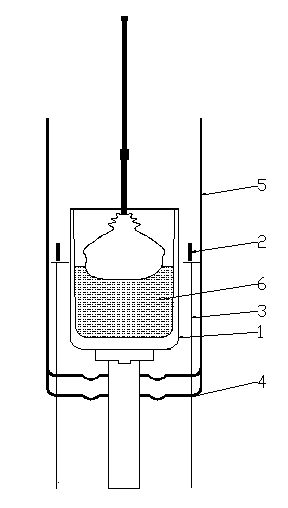

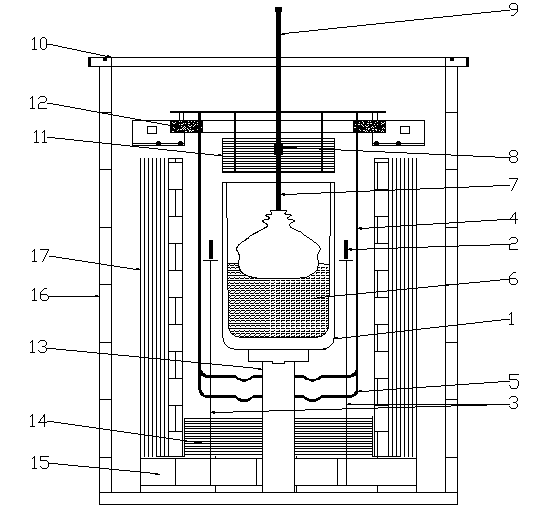

[0032] Embodiment: The dynamic temperature field method preparation of F264mm C-axis sapphire crystal

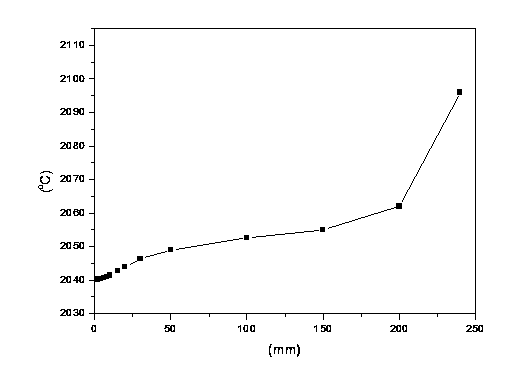

[0033] The preparation of the large-size C-axis sapphire crystal of this embodiment is as follows figure 2 performed in a high temperature furnace as indicated. Al with a purity of 99.9995% 2 o 3 Put the raw materials into a tungsten crucible of φ270mm, put the crucible into the furnace, seal the furnace, feed the cooling water into the whole system, adjust the flow rate of the cooling water so that the temperature of the cooling water at the outlet is room temperature ± 2 o C range, vacuumed to 6'10 -3 After Pa, start to heat the main heating element on the side wall at a speed of 4kw / h, and at the same time heat the main heating element on the bottom at a speed of 5.6kw / h. After reaching the target power, keep the temperature until the raw materials are completely melted, drive away the bubbles in the melt, and keep the temperature for 1 hour to stabilize the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com