Method for removing bubbles in sapphire crystal growth melt

A sapphire crystal and crystal growth technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of deterioration of crystal growth quality, unstable solid-liquid interface, difficult to use, etc., and achieve a bubble-free defect density. Effect

Inactive Publication Date: 2014-10-01

浙江特锐新能源有限公司

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

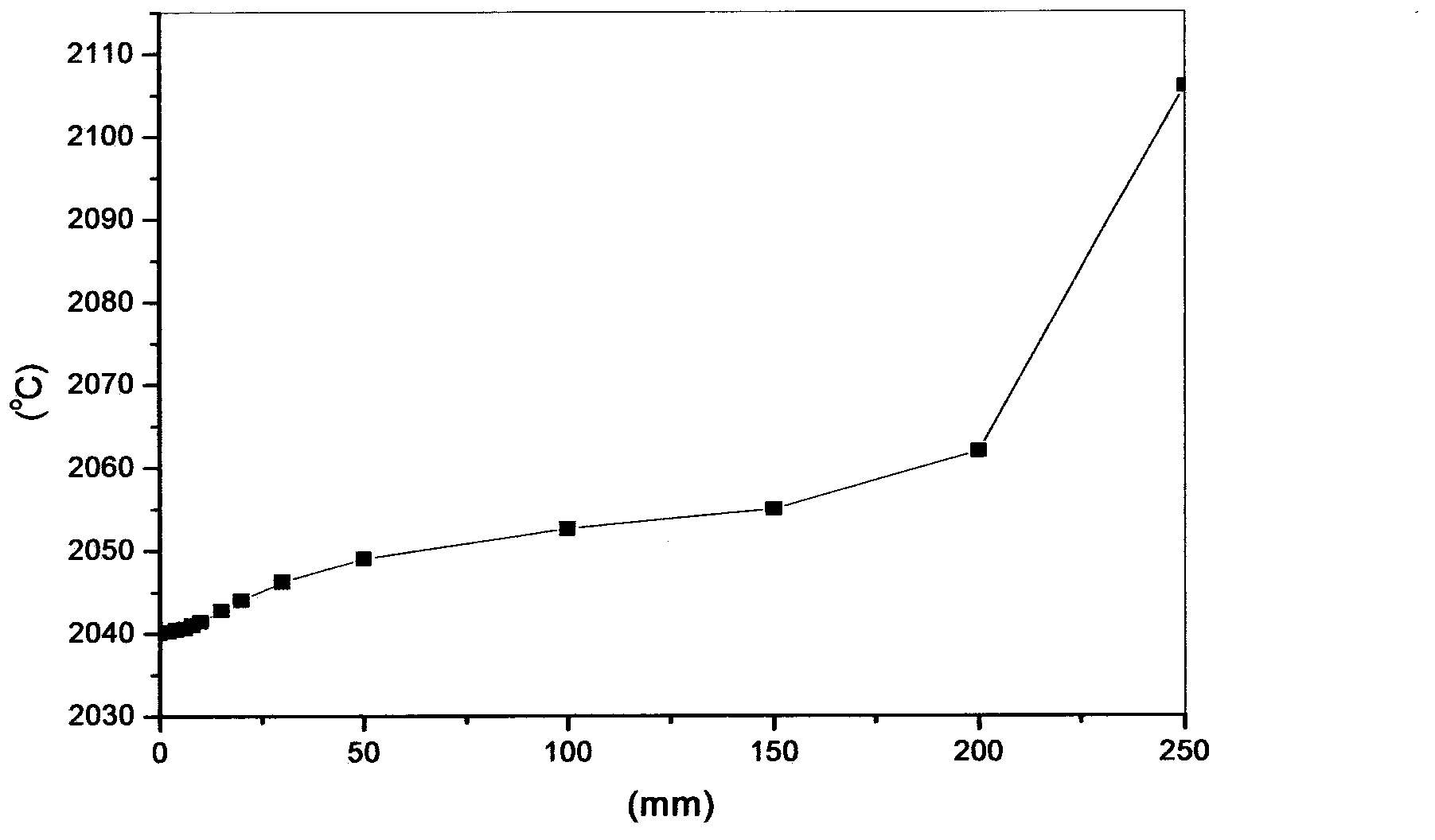

During the crystal growth process, the convective pattern of the melt is very important to the crystal growth. Mechanical agitation will have a serious impact on the convective pattern of the melt, making the solid-liquid interface unstable, and producing a large number of defects in the melt, resulting in a change in the quality of crystal growth. Bad, moreover, in the melt above 2050°C, the stirring rod will generate impurities in the melt, and these impurities will quickly diffuse in the melt through stirring, and some of them will enter the crystal, resulting in impurity defects in the crystal

Therefore, although this method realizes that the bubbles in the melt need to be driven out, the method used will seriously reduce the quality of crystal growth, and it is difficult to use in actual crystal growth.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

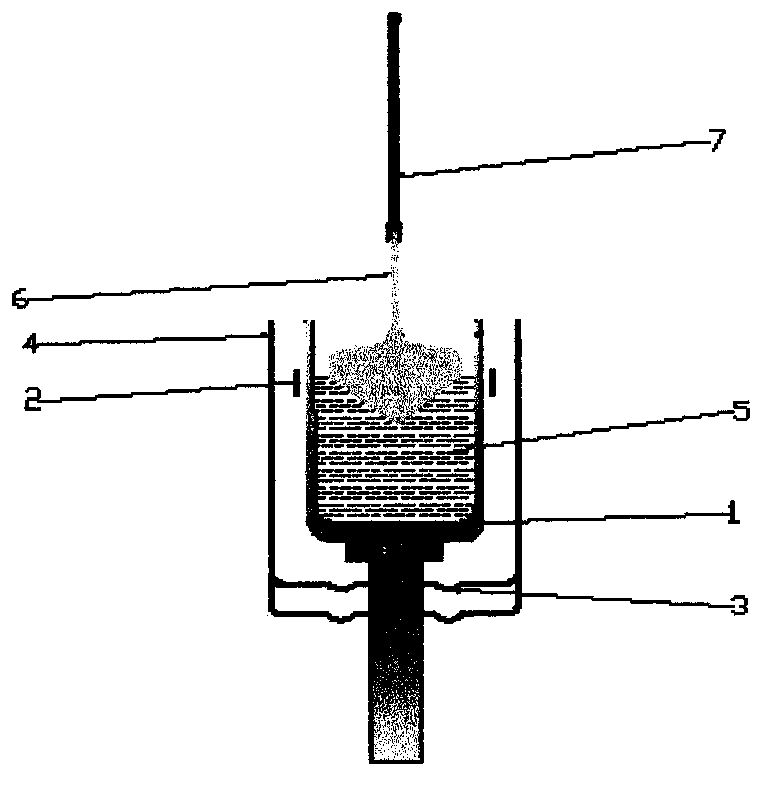

The invention relates to a method for removing bubbles in a sapphire crystal growth melt. The method is characterized in that a device for removing the bubbles comprises a heater at the bottom of a crucible, an outer heater on the side wall of the crucible and an auxiliary heater at the upper part of the crucible, wherein the temperatures of the three heaters can be controlled separately. By independently regulating and controlling the power of the three heaters, when a crystal growth raw material is melted, the bubbles in the raw material melt can be removed in different sections through a dynamic temperature field. The heaters are made of tungsten filament. The method has the remarkable benefits that under the condition that the growth melt and the crystal growth process are not influenced, the bubbles in the melt are removed, obtained sapphire crystal is free of bubbles, the crystal quality is improved, and the utilization rate of a crystal material is improved by 1.3 times.

Description

Technical field [0001] The invention relates to a method for driving bubbles in a sapphire crystal growth melt. Background technique [0002] Large-size sapphire crystals have excellent optical and mechanical properties, good physical and chemical stability, high strength, and high hardness. They can work at a high temperature of 1800°C. They are used as a lining for LEDs, large-scale integrated circuits SOI and SOS, and superconducting nanostructure films. It can be used as window material for infrared military devices, space satellites and high-intensity lasers. With the development of application requirements, the required crystal size continues to increase, and its quality requirements continue to increase. However, due to the increase of crystal size and the increase of raw materials in the crucible, it is very important to remove bubbles in the melt. Otherwise, macroscopic defects such as micro bubbles will be generated in the crystals obtained by growth, which will seriou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C30B11/00C30B29/20

Inventor 万尤宝陶翔刘嘉李世香

Owner 浙江特锐新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com