Welding process of water feed pump of nuclear power plant conventional island

A welding process and main water pump technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of difficult welding and preheating of outlet pipes, reduce the probability of defects, eliminate the tendency of cracks, and save energy. resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

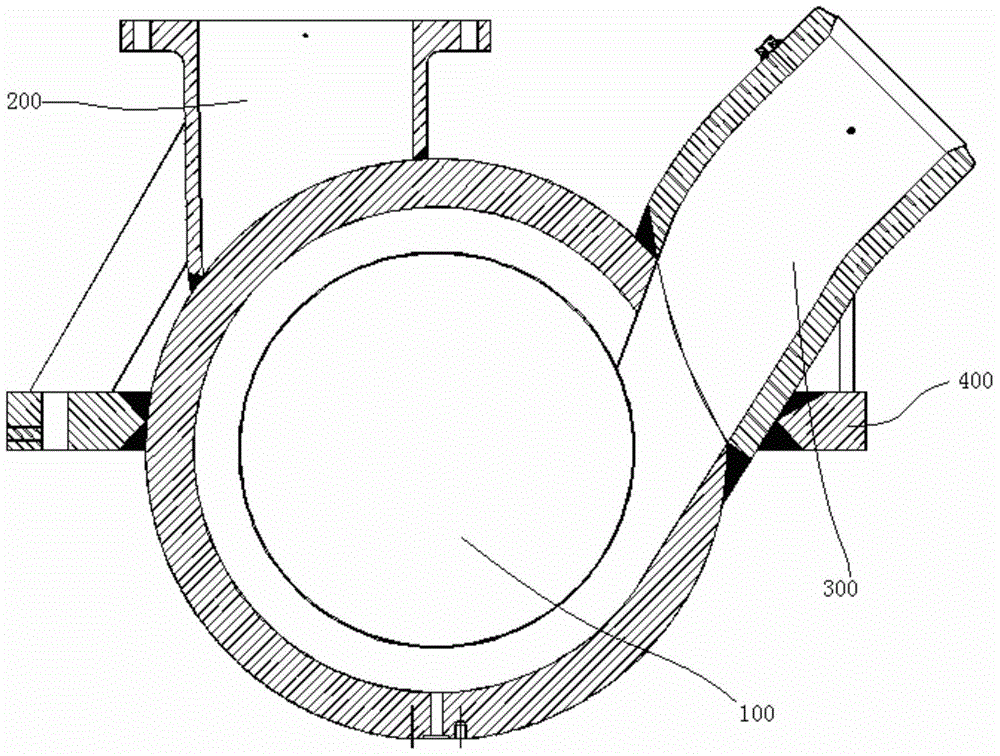

[0069] (1) Groove processing, the grooves are respectively processed at the joints of the inlet pipe, outlet pipe, side plate and rib plate and the pump body;

[0070] (2) Preheat the grooves on each component before welding, and the preheating temperature is controlled at 150°C to 300°C;

[0071] (3) After the preheating is completed, welding is carried out. Firstly, the manual electrode is used for welding. The manual electrode adopts DC reverse connection, the welding current is 80A, the welding voltage is 18V, and the welding speed is 150mm / min. / 3, stop welding, and then continue welding with MIGA welding, until the welding is completed, continue welding with MIGA welding, adopt DC reverse connection, welding current 180A, welding voltage 24V, welding speed 200mm / min.

[0072] (4) Inspection after welding.

Embodiment 2

[0074] (1) Groove processing, the grooves are respectively processed at the joints of the inlet pipe, outlet pipe, side plate and rib plate and the pump body;

[0075] (2) Preheat the grooves on each component before welding, and the preheating temperature is controlled at 150°C to 300°C;

[0076] (3) After the preheating is completed, welding is carried out. First, the manual electrode is used for welding. The manual electrode adopts DC reverse connection, the welding current is 90A, the welding voltage is 19V, and the welding speed is 160mm / min. / 3, stop welding, and then continue welding with MIGA welding until the welding is completed, continue welding with MIGA welding, adopt DC reverse connection, welding current 190A, welding voltage 25V, welding speed 215mm / min.

[0077] (4) Inspection after welding.

Embodiment 3

[0079] (1) Groove processing, the grooves are respectively processed at the joints of the inlet pipe, outlet pipe, side plate and rib plate and the pump body;

[0080] (2) Preheat the grooves on each component before welding, and the preheating temperature is controlled at 150°C to 300°C;

[0081] (3) After the preheating is completed, welding is carried out. Firstly, the manual electrode is used for welding. The manual electrode adopts DC reverse connection, the welding current is 100A, the welding voltage is 20V, and the welding speed is 170mm / min. / 3, stop welding, and then continue welding with MIGA welding, until the welding is completed, continue welding with MIGA welding, adopt DC reverse connection, welding current 220A, welding voltage 26V, welding speed 230mm / min.

[0082] (4) Inspection after welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com