Selective laser melting device

A technology of laser selective melting and equipment, applied in the direction of additive processing, etc., can solve the problems of finished products such as porosity, inclusions, crack enlargement, affecting the quality of the finished product, falling on the powder bed, etc., to improve the quality of the finished product, ensure the accuracy uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

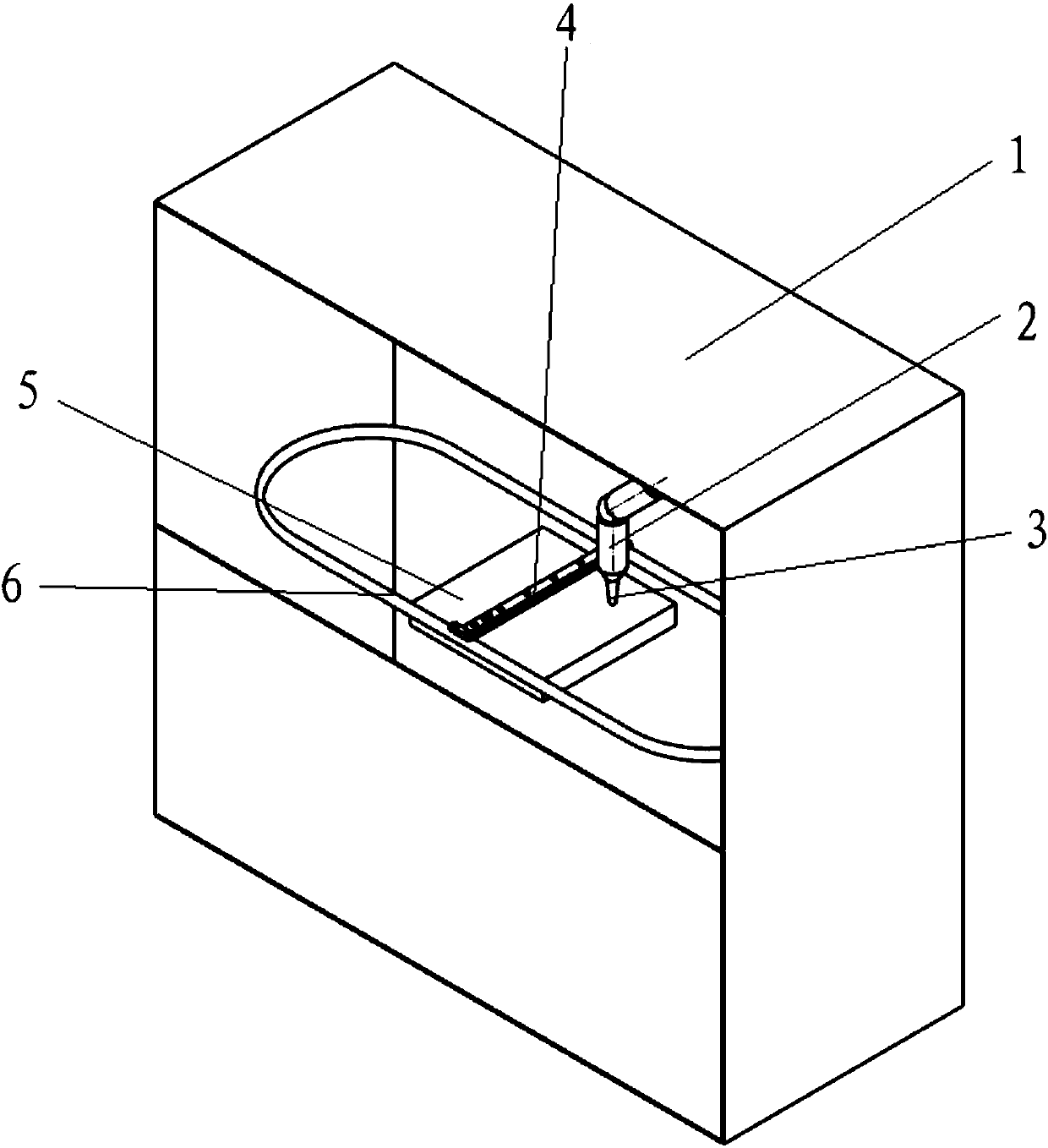

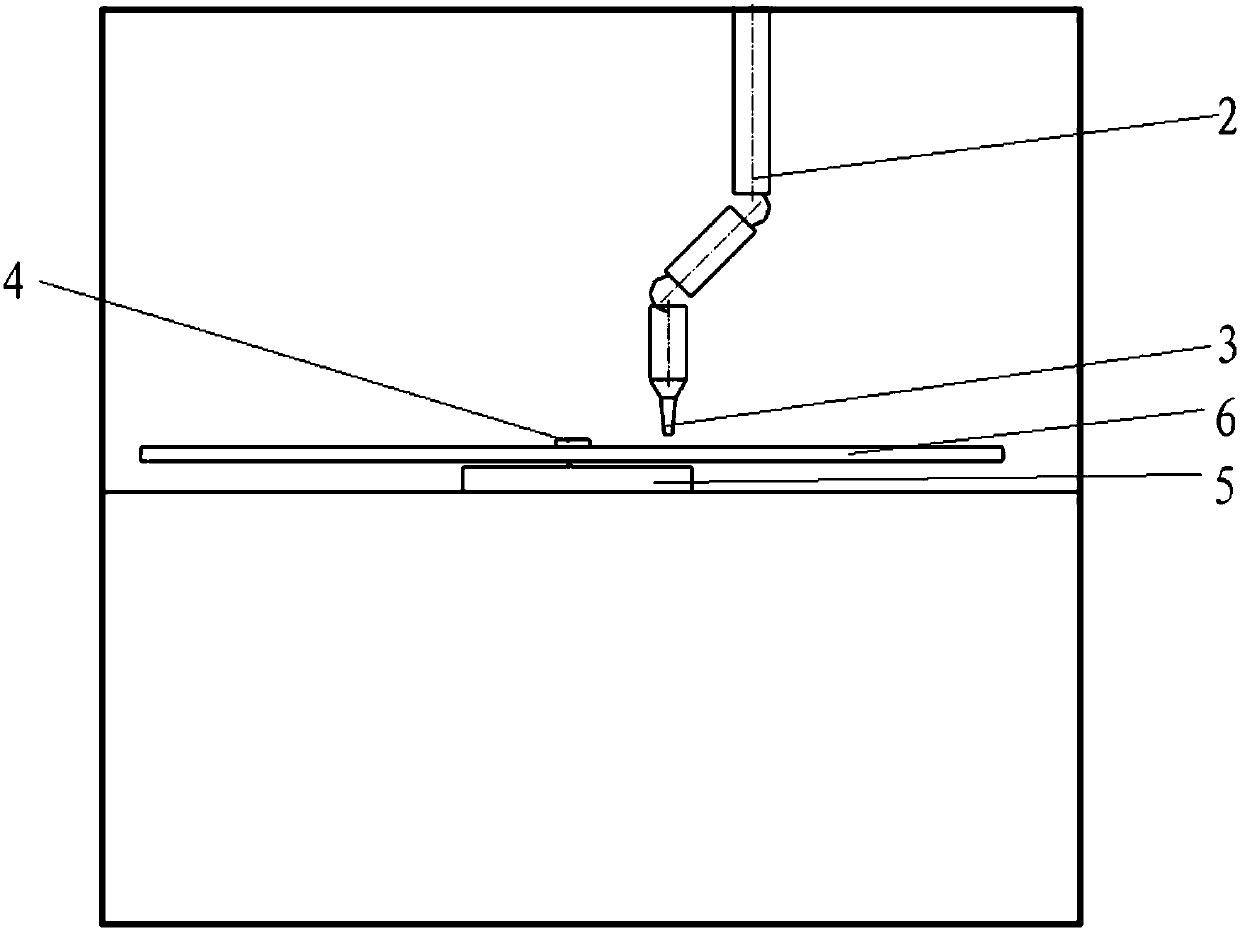

[0026] Refer to attached figure 1 and 2 As shown, the laser selective melting equipment of the present invention includes a rigid powder spreading device, a milling cutter cutting device and a control device. Both the rigid powder spreading device and the milling cutter cutting device are arranged in the processing chamber 1 of the laser selective melting equipment.

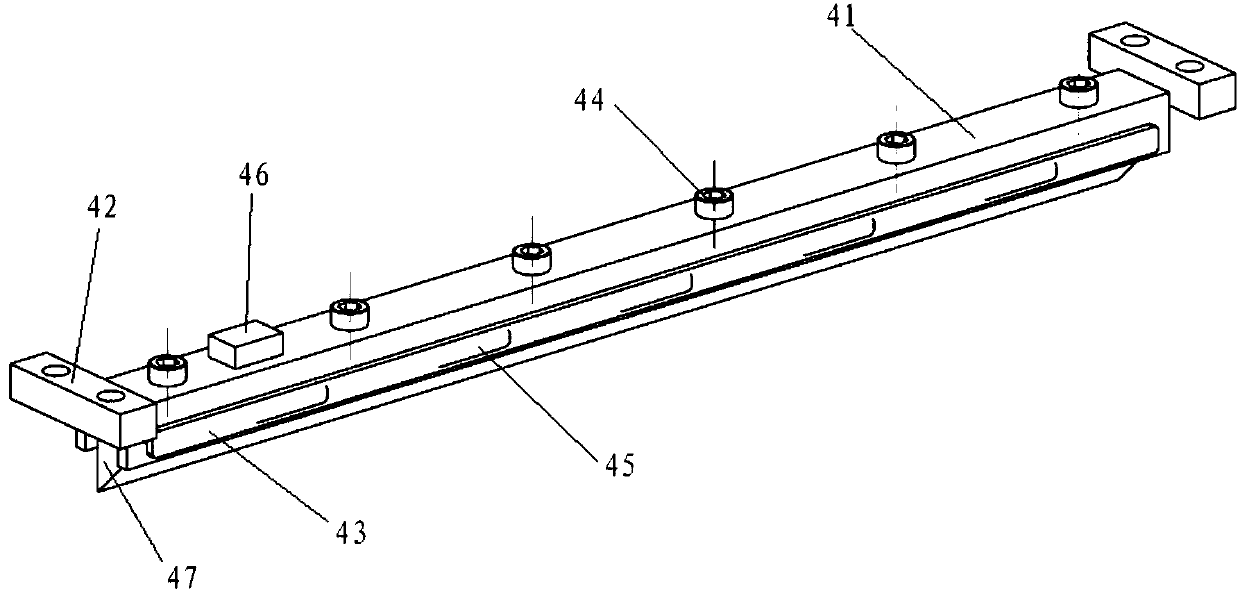

[0027] The rigid powder spreading device includes a scraper mechanism 4 , a rail mechanism 6 , a power mechanism and an overload current detection mechanism 46 . The scraper mechanism 4 is used to realize the rigid powder spreading action of the selective laser melting equipment. The guide rail mechanism 6 can adopt any existing guide rail structure, and a circular track structure is adopted in this embodiment. The power mechanism drives the scraper mechanism 4 to move along the guide rail of the guide rail mechanism 6 to realize the rigid powder spreading action of the scraper on the surface of the molten lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com