Mask group structure

A group structure and mask technology, which is applied in the field of mask group structure that effectively improves production efficiency, can solve the problems that the production speed of masks cannot keep up, the shape changes, and the defective rate of masks is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] The easy-tear line (such as the first easy-tear line, the second easy-tear line and the third easy-tear line) mentioned in the following description is a structure widely used in product packaging. An easy-tear line can be formed on the product package to facilitate tearing off part of the package, so that users can easily open the package through the easy-tear line with steady force. The easy-to-tear line is to use the laser flying cutting technology to form an intermittent line segment on the product packaging by cutting with a short line spacing. The part cut by the laser is thin and impenetrable, while the part not cut by the laser remains in the original packaging thickness of. Now the present invention applies the easy-tear line to the structure of the mask set, please refer to the following descriptions of various embodiments of the structure of the mask set with the easy-tear line.

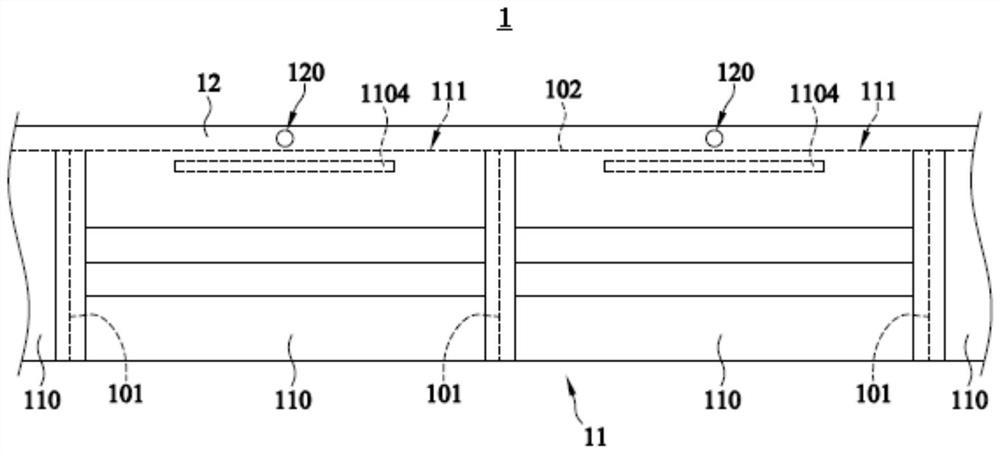

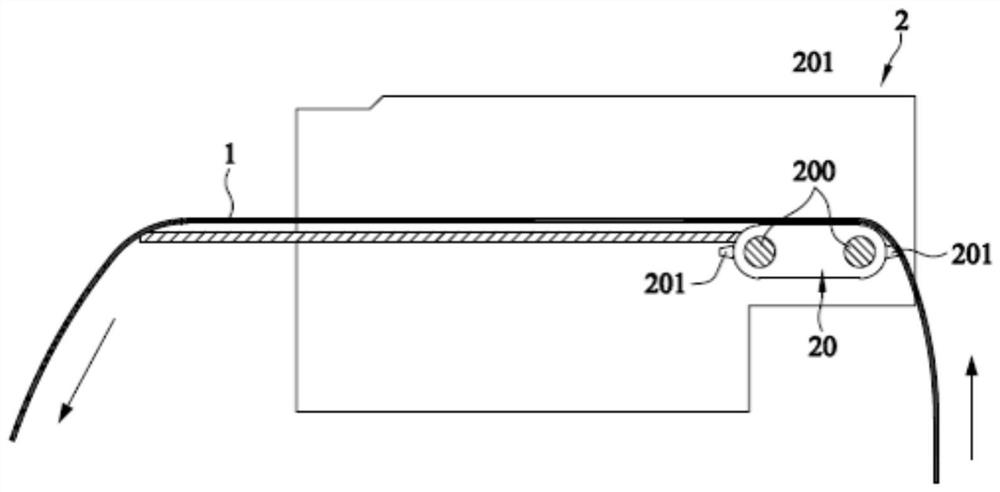

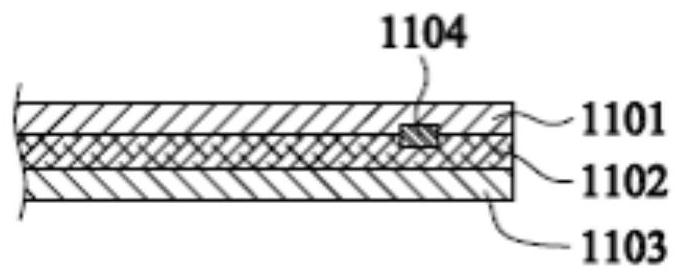

[0041] see Figure 1 to Figure 3 , figure 1 It is a schematic top view of th...

no. 2 example

[0050] see Figure 4 , which is a schematic top view of the structure of the mask set according to the second embodiment of the present invention. Such as Figure 4 Shown, the mouth mask group structure 1a of the present embodiment and figure 1 The mask set structure 1 shown is similar, the difference lies in that the mask set structure 1 a of this embodiment also includes a second positioning portion 13 . The second positioning portion 13 is connected to the second side 112 of the mask group body 11, the second side 112 of the mask group body 11 is opposite to the first side 111, and the second positioning portion 13 is connected to the second side of the mask group body 11. There is a third easy-tear line 103 between the two sides 112 . The second positioning portion 13 includes at least two holes 130, and the third easy-tear line 103 and the first easy-tear line 101 are not parallel to each other. In this embodiment, the third easy-tear line 103 and the first tear line 1...

no. 3 example

[0053] see Figure 5 and Image 6 , Figure 5 It is a schematic top view of the structure of the mask group according to the third embodiment of the present invention. Image 6 for Figure 5 The schematic diagram of the connection between the cover body and the ear strap line is shown. Such as Figure 5 Shown, the mouth mask group structure 1b of the present embodiment and Figure 4 The mask group structure 1a shown is similar, the difference is that the first easy-tear line 101b of the mask group structure 1b of the present embodiment extends from the mask group body 11 to the first positioning part 12 and the second positioning part 13, so that the second The easy-tear line 102 and the third easy-tear line 103 respectively intersect the first easy-tear line 101b. In addition, in this embodiment, the number of holes 120 in the first positioning part 12 is more than two, these holes 120 are adjacent to the first easy-tear line 101b, and these holes 120 are adjacent to ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com