Binder for injection molding and composition containing same for manufacturing molding objects

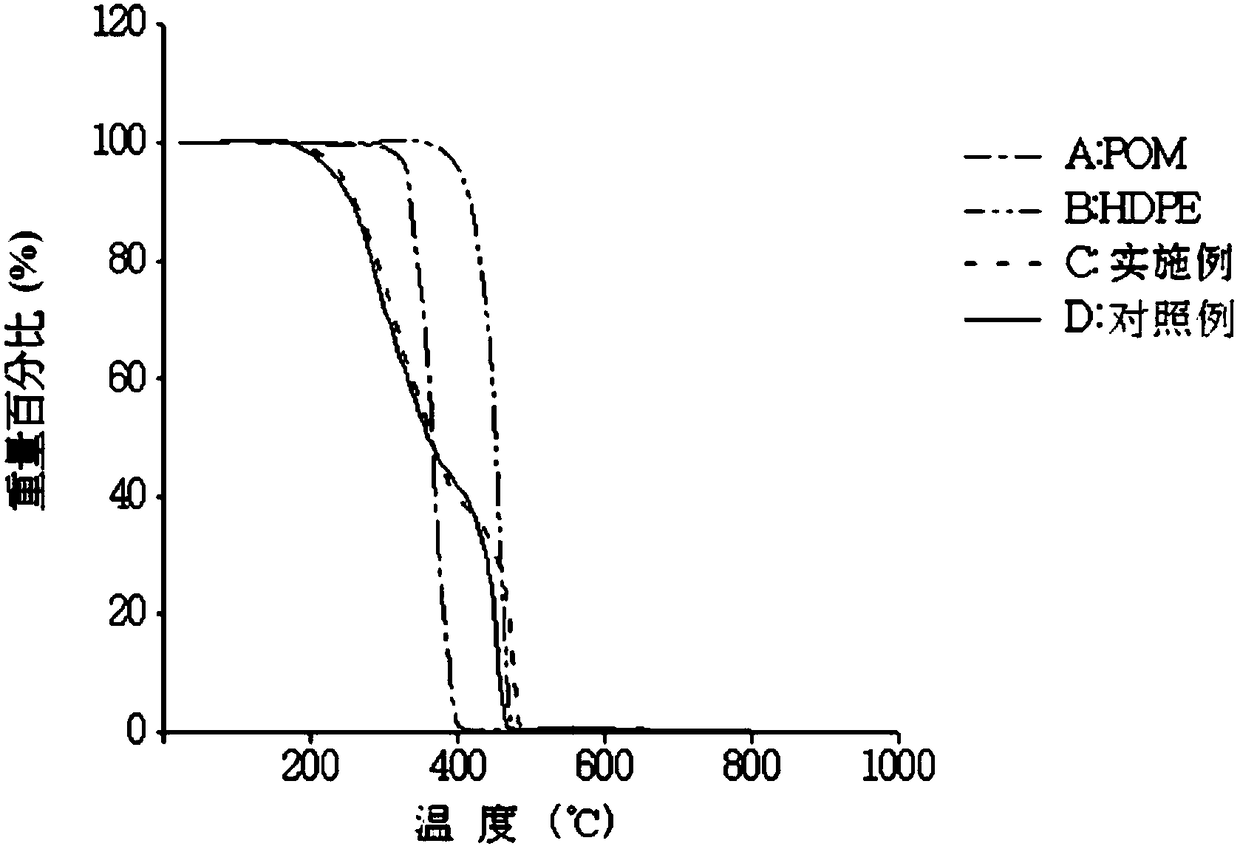

A technology of injection molding and bonding agent, applied in the field of bonding agent for metal powder or ceramic powder injection molding, can solve the problems of incomplete casting, affecting compatibility, inconsistent rate of thermal decomposition, etc., to extend the temperature range and improve compatibility. , the effect of reducing the probability of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

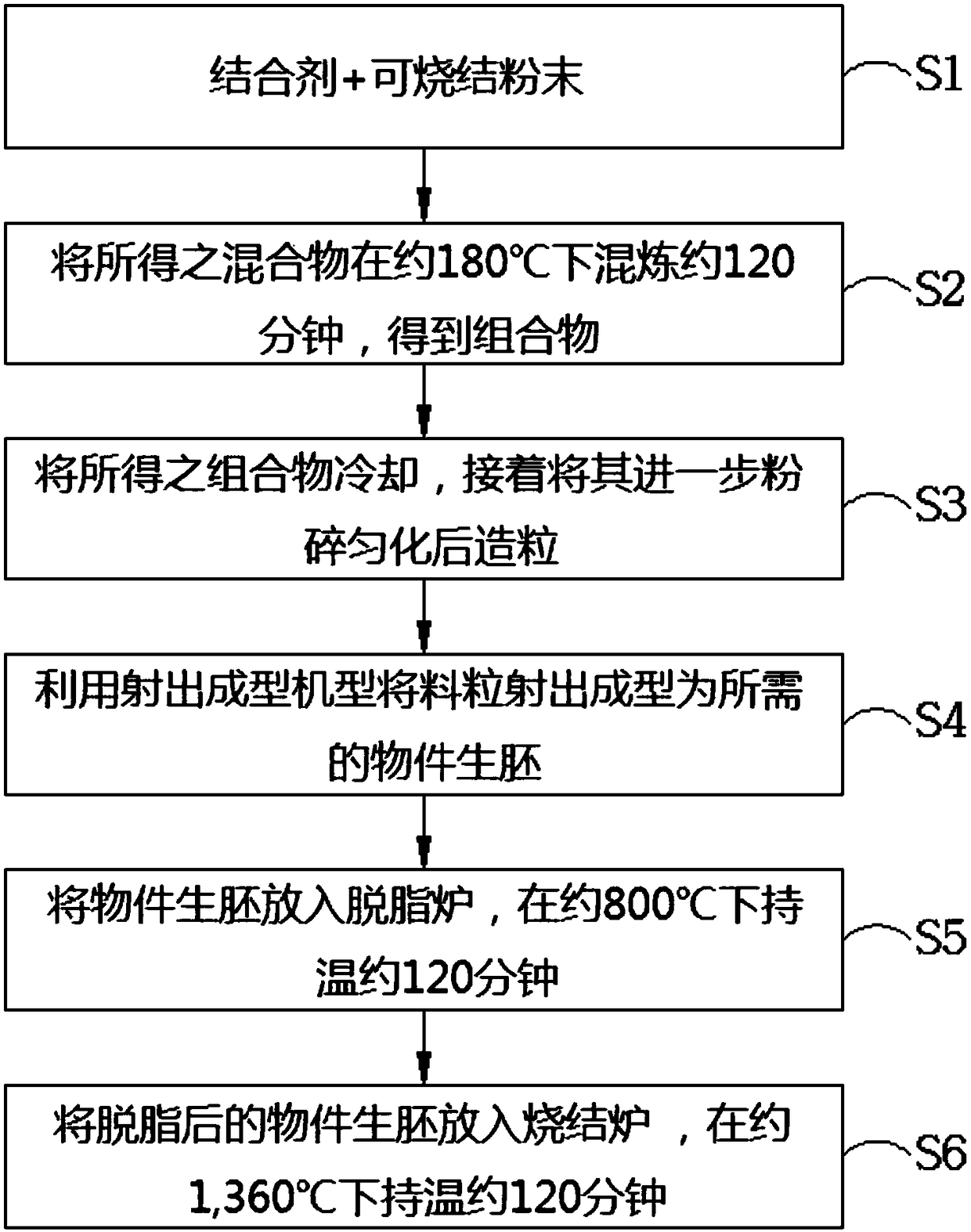

[0020] The first embodiment of the present invention provides a five-component binder composition for injection molding, which may contain polyolefins with maleic anhydride groups, polyolefin compounds, polyoxymethylene, hard Fatty acids and waxes. In this embodiment, the average molecular weight of the polyolefin bearing maleic anhydride groups may be from about 90,000 to about 110,000, preferably about 100,000. The polyolefin compound may comprise a density of about 0.950 to about of high-density polyethylene (HDPE) or a density of about 0.915 to about Low-density polyethylene (LDPE), preferably high-density polyethylene. The wax can be selected from the group consisting of paraffin wax, beesicum wax, carnauba wax, microcrystalline wax and combinations thereof, preferably, but not limited to, the group consisting of paraffin wax, microcrystalline wax and combinations thereof.

[0021] According to this first embodiment, the polyolefin with maleic anhydride groups, polyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com