Intelligent custom furniture assembling component quality inspection system and method

A technology for assembling parts and furniture, applied in the direction of measuring devices, instruments, etc., can solve the problems of inconsistent specifications and dimensions of assembled parts, low accuracy, insufficient clarity, etc., to improve the accuracy of quality inspection, improve image accuracy, reduce Effect of Defect Chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0057] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

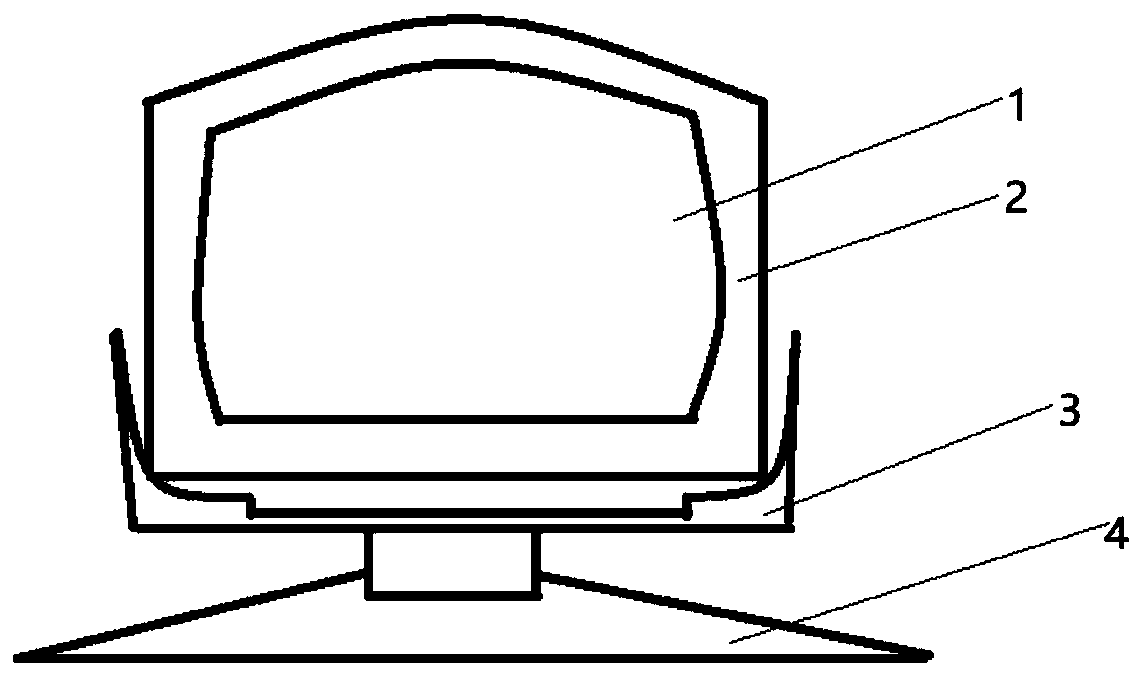

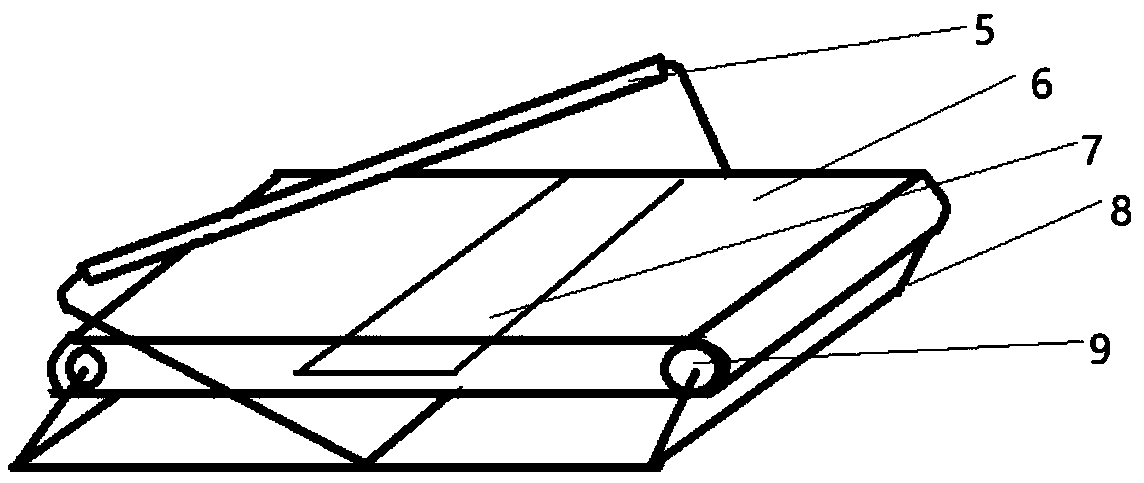

[0058] The display screen 1 is embedded on the casing 2, the casing 2 is placed on the tray 3, the two ends of the tray 3 are wrapped with the casing 2, the tray 3 is fixedly connected to the base 4 through nuts, and the gamma ray lamp 5 Fixedly connected on the bracket 8 by nuts, the conveyor belt 6 is wrapped around the outside of the power take-off shaft 9, a sensor 7 is placed in the middle of the power take-off shaft 9, and the sensor 7 is placed between the conveyor belts 6, and the bracket 8 Connect to the power take-off shaft 9 through a nut.

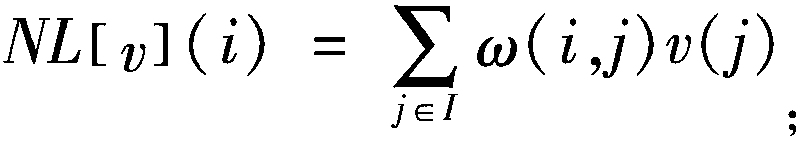

[0059] The quality inspection method for intelligent customized furniture assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com