Electronic component pin regulating device

A technology of electronic components and circuit boards, which is applied in the field of electronic component leg fixers, can solve problems such as installation defects, unfavorable production line time costs, and manual operation difficulties, so as to reduce the probability of product defects, facilitate manual operations, and avoid easily deformed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail by the following specific embodiments in conjunction with the accompanying drawings, as follows:

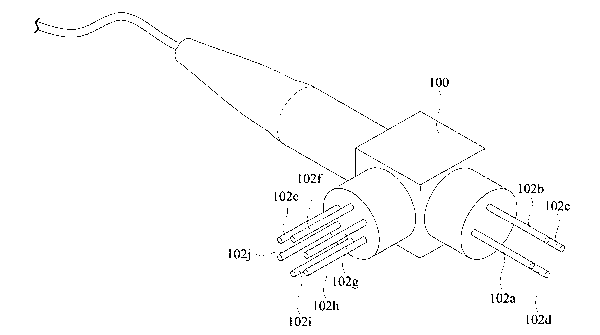

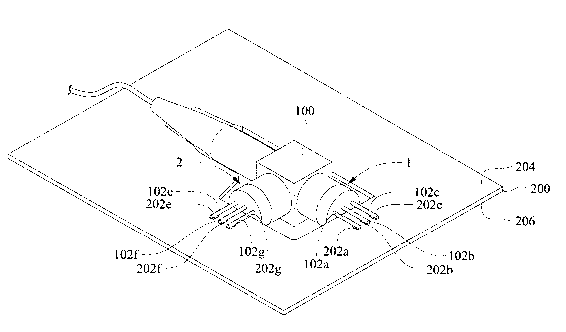

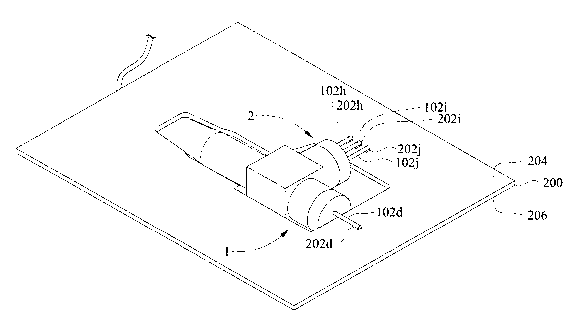

[0042] Please refer to Figure 2 to Figure 3 , figure 2 It is a schematic diagram of the electronic component foot adjuster of the present invention installed on the first surface of the electronic component and the circuit board; image 3 It is a schematic diagram showing that the electronic component leg fixer of the present invention is installed on the second surface of the electronic component and the circuit board. The electronic component leg adjuster 1 of the present invention is used for mounting the electronic component 100 on the circuit board 200, fixing and fixing the plurality of pins 102a-102j of the electronic component 100, so that the pins 102a-102j are connected There are a plurality of connection points 202a-202j ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com