A kind of production method of aluminum-magnesium alloy coil

A production method and aluminum-magnesium alloy technology, applied in the production field of aluminum-magnesium alloy coils, can solve problems such as long production cycle, high production cost, and cumbersome production process, and achieve streamlined production process, reduced production cost, and shortened production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

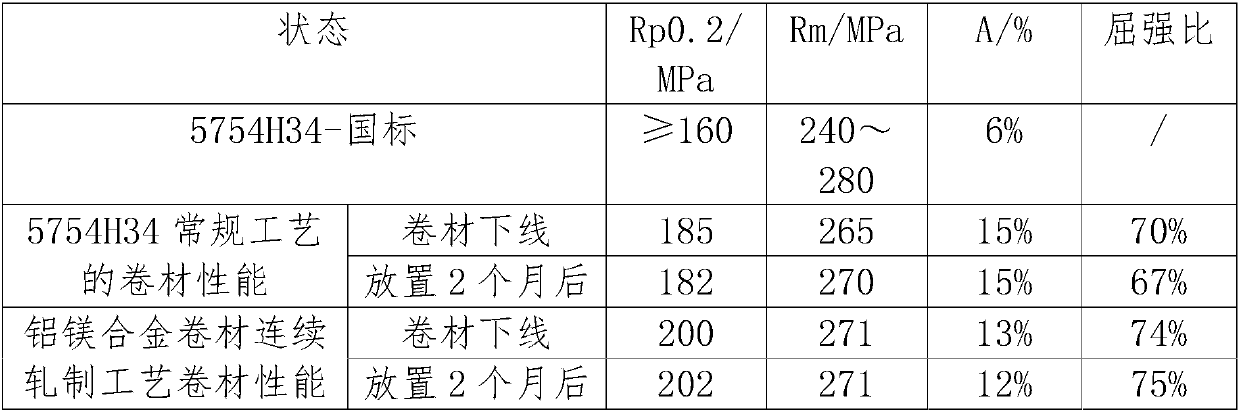

Embodiment 1

[0007] A kind of production method of aluminum-magnesium alloy coil material of this example, comprises the following several steps: the first step smelting: 1).Batching: with the pure aluminum ingot of batching, add a small amount of aluminum alloy waste material, Fe, Si, Cu The master alloy ingot is loaded into the melting furnace, and the weight percentage of the composition is: Mg2.2%, Mn0.1%, Cr0.15%, Fe2 / s, flash point 120°C; the fifth step of cleaning: the coiled material passes through the cleaning machine to remove oil stains and sundries on the surface of the coiled material; the sixth step of intermediate annealing: put the coiled material into a box furnace for complete recrystallization annealing, annealing The temperature is 330°C, the holding time is 20h, and the high-speed two-pass continuous cold rolling is carried out when the coil end surface temperature is 70°C; the seventh step is high-speed two-pass continuous cold rolling: a. Use single-stand SMS six-roll...

Embodiment 2

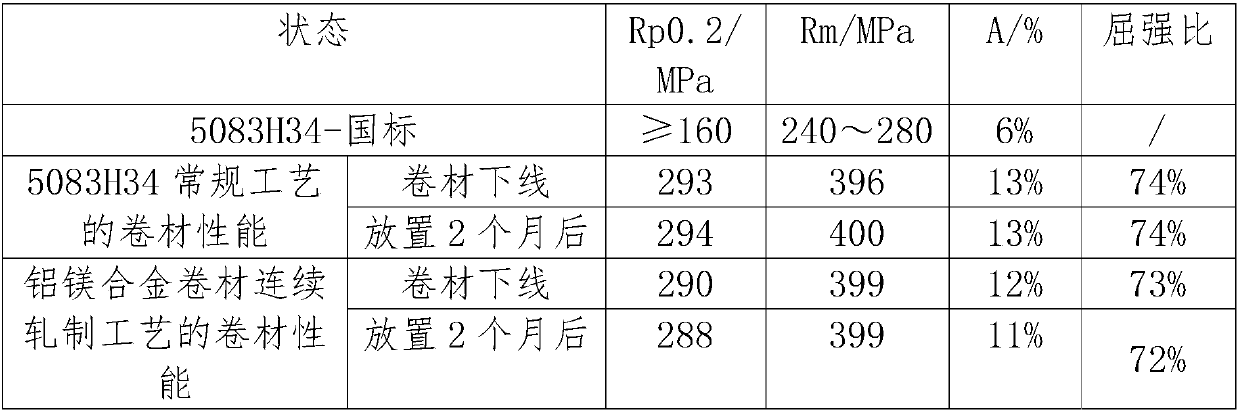

[0012] A kind of production method of aluminum-magnesium alloy coil material of this example, comprises the following several steps: the first step smelting: 1).Batching: with the pure aluminum ingot of batching, add a small amount of aluminum alloy waste material, Fe, Si, Cu The master alloy ingot is loaded into the melting furnace, and the weight percentage of the composition is: Mg3.85%, Mn0.55%, Cr0.25%, Fe2 / s, flash point 127.5°C; the fifth step of cleaning: the coiled material is cleaned by a cleaning machine to remove oil stains and sundries on the surface of the coiled material; the sixth step of intermediate annealing: the coiled material is put into a box furnace for complete recrystallization annealing treatment, annealed The temperature is 355°C, the holding time is 24h, and the high-speed two-pass continuous cold rolling is carried out when the coil end surface temperature is 80°C; the seventh step is high-speed two-pass continuous cold rolling: a. Use single-stand...

Embodiment 3

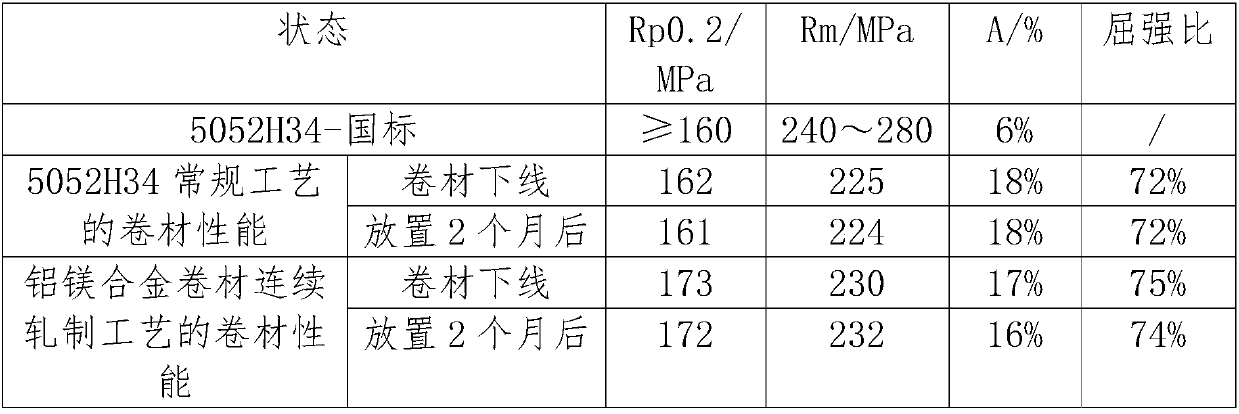

[0017]A kind of production method of aluminum-magnesium alloy coil material of this example, comprises the following several steps: the first step smelting: 1).Batching: with the pure aluminum ingot of batching, add a small amount of aluminum alloy waste material, Fe, Si, Cu The master alloy ingot is loaded into the melting furnace, and the weight percentage of the composition is: Mg5.5%, Mn1.0%, Cr0.35%, Fe2 / s, flash point 135°C; the fifth step of cleaning: the coiled material passes through the cleaning machine to remove oil stains and sundries on the surface of the coiled material; the sixth step of intermediate annealing: put the coiled material into a box furnace for complete recrystallization annealing, annealing The temperature is 380°C, the holding time is 28h, and the high-speed two-pass continuous cold rolling is carried out when the coil end surface temperature is 90°C; the seventh step is high-speed two-pass continuous cold rolling: a. Use single-stand SMS six-rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com