Method for reducing longitudinal division of weather-proof steel continuously cast slab

A technology of weathering steel and slab, applied in the field of continuous casting, can solve the problem that longitudinal crack defects on the surface of slab and thin slab are not stably controlled, so as to reduce the incidence of longitudinal cracks, stabilize the formation speed, and improve the casting speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

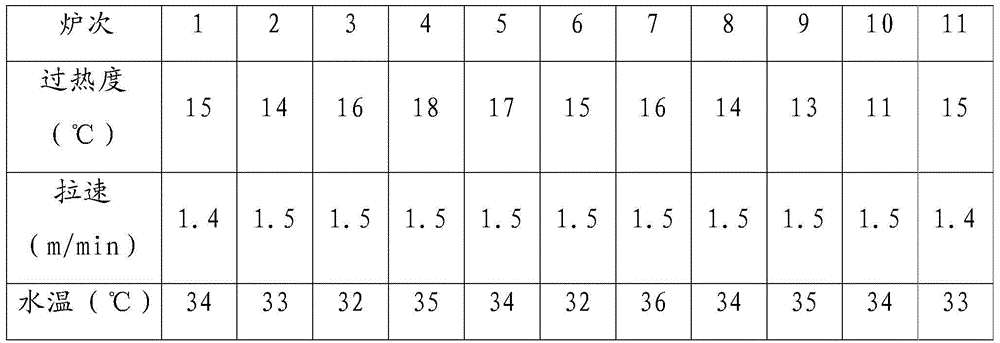

[0024] 300 tons of molten steel ladle, 11 furnaces of continuous casting, see Table 1 for the superheat of molten steel in the casting tundish, the casting speed of the slab, and the temperature of the cooling water at the mold inlet.

[0025] Table 1 Casting molten steel superheat, slab casting speed, crystallizer inlet cooling water temperature

[0026]

[0027] At the same time, the taper of the crystallizer is increased by 0.5mm on the narrow side of the original basis, and the basicity of the mold flux is controlled to 1.40 and the viscosity η 1300℃ The control is 0.70 poise. After the continuous casting, the longitudinal crack occurrence rate of the obtained weathering steel continuous casting slab was 0.57%.

Embodiment 2

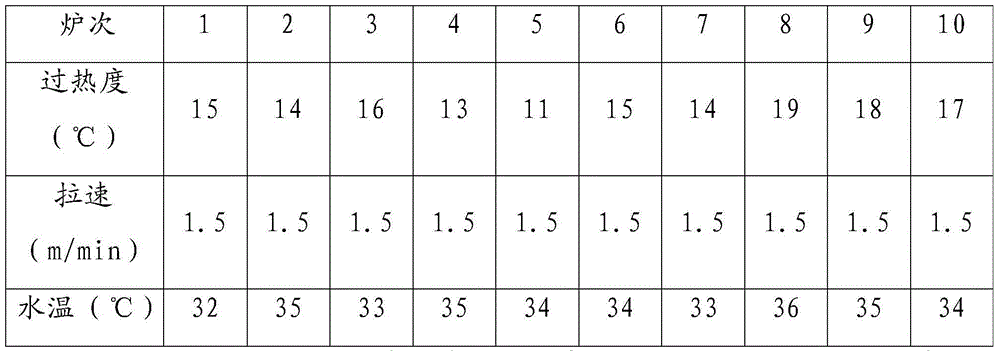

[0029] 300 tons of ladle, continuous casting 10 furnaces, casting tundish superheat, slab casting speed, crystallizer inlet cooling water temperature are shown in Table 2.

[0030] Table 2 Casting molten steel superheat, slab casting speed, mold inlet cooling water temperature

[0031]

[0032] At the same time, the taper of the crystallizer is increased by 0.5mm on the narrow side of the original basis, and the basicity of the mold flux is controlled to 1.50 and the viscosity η 1300℃ The control is 0.80 poise. After the continuous casting, the longitudinal crack occurrence rate of the obtained weathering steel continuous casting slab was 0.63%.

Embodiment 3

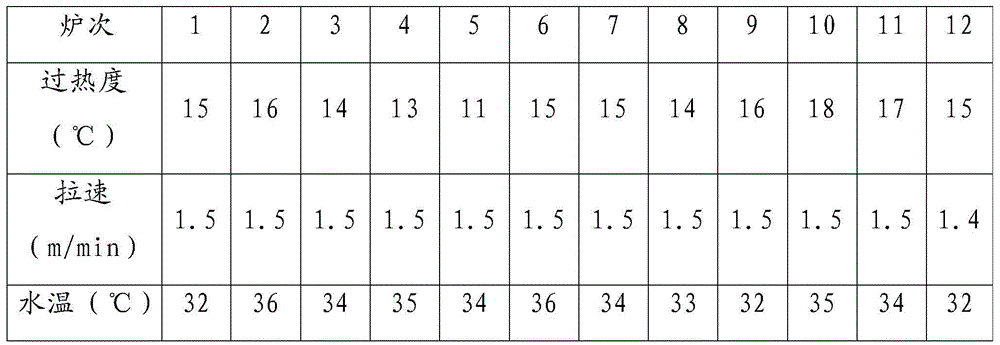

[0034] 300 tons ladle, continuous casting 12 furnaces, casting tundish superheat, slab casting speed, crystallizer inlet cooling water temperature are shown in Table 3.

[0035] Table 3 Casting molten steel superheat, slab casting speed, mold inlet cooling water temperature

[0036]

[0037] At the same time, the taper of the crystallizer is increased by 0.5mm on the narrow side of the original basis, and the basicity of the mold flux is controlled to 1.45 and the viscosity η 1300℃ The control is 0.75 poise. After the continuous casting, the longitudinal crack occurrence rate of the obtained weathering steel continuous casting slab was 0.52%.

[0038] The invention provides a method for reducing the longitudinal cracks of weathering steel continuous casting slabs. By increasing the casting speed, the production efficiency of crack-sensitive steel types is improved, the mold cooling effect is improved, the number of crystallizer bonding alarms is reduced, and the The incid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com