Method for quickly preparing hypereutectic Al-Si alloy bar billet at low cost

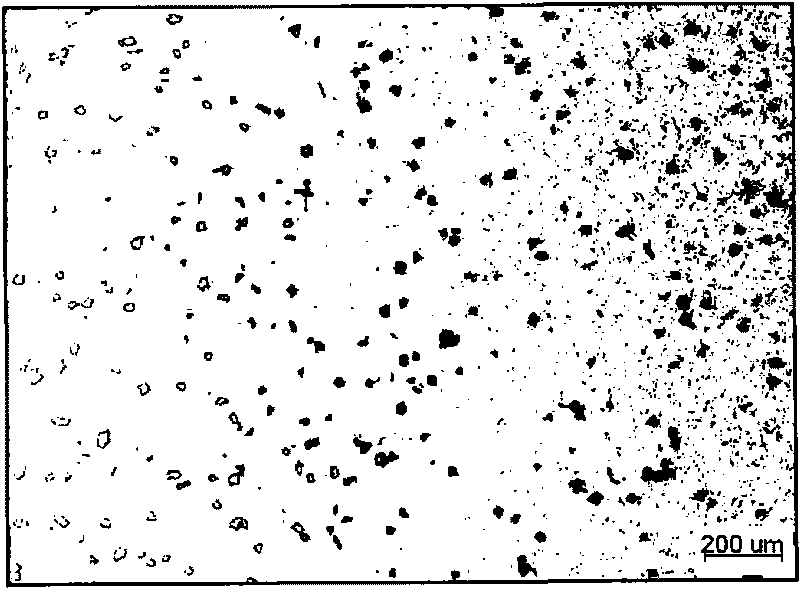

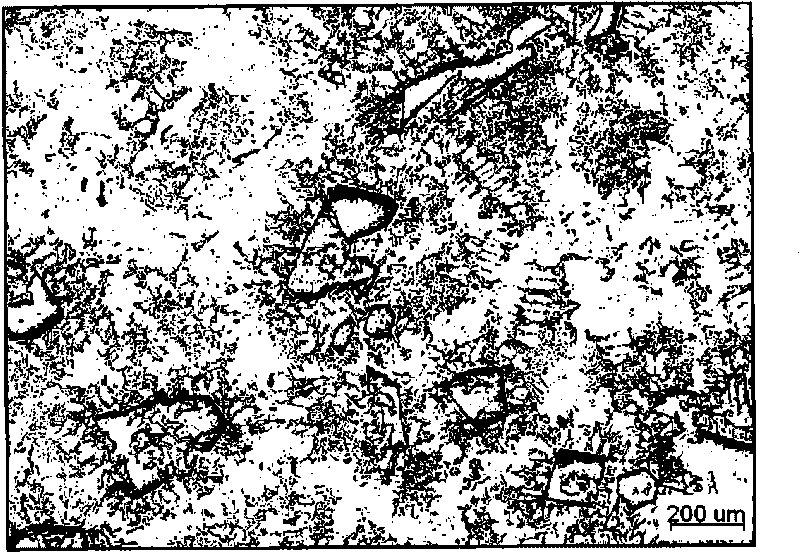

An aluminum-silicon alloy and hypereutectic technology is applied in the field of low-cost and rapid preparation of hypereutectic aluminum-silicon alloy billets, which can solve the problem of high preparation cost, limited billet volume, and difficulty in continuous preparation of hypereutectic aluminum-silicon alloy billets. problem, to achieve the effect of uniform distribution, high production efficiency, and fine silicon grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

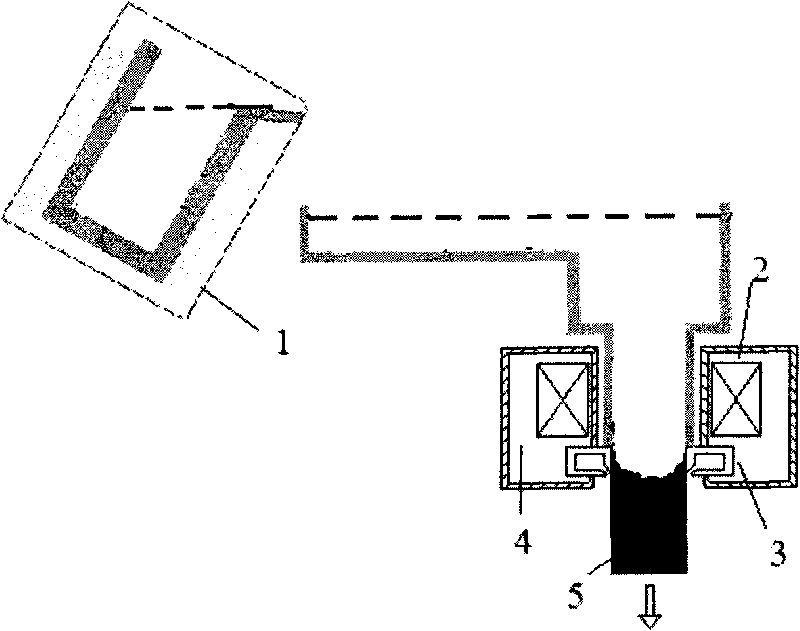

Method used

Image

Examples

Embodiment 1

[0021] The Φ76mm American brand A390 aluminum alloy billet with a silicon content of 16% to 18% used in the swash plate parts of the automobile air-conditioning compressor:

[0022] (1) Under the protection of argon, place the aluminum ingot in an intermediate frequency induction furnace to melt into an alloy melt. When the temperature of the melt rises to 840°C, transfer it to the tundish 1, add the melt slag remover, and fully Stir and keep warm for 20 minutes and remove the scum;

[0023] (2) When the melt temperature drops to 820°C, add an Al-P master alloy modifier with a mass percentage of 2‰, stir evenly, and keep warm for 30 minutes;

[0024] (3) When the melt temperature drops to 790°C, add a refining agent with a mass percentage of 4‰, fully stir, and remove the scum after 15 minutes of heat preservation;

[0025] (4) Carry out degassing treatment to the alloy melt: feed hexachloroethane into the melt, the gas pressure is 0.01MPa, keep warm for 15 minutes, and leave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com