Vertical semi-solid state cast rolling device and method

A semi-solid, cast-rolling technology, which is applied in the field of aluminum alloy casting-rolling equipment and manufacturing, can solve the problems of low production efficiency, easy blockage of casting nozzles, macro-segregation and micro-segregation, etc., to improve production efficiency, reduce alloy element segregation defects, The effect of reducing superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Figure 5 A schematic diagram of the microstructure of the AA6111 aluminum alloy cast-rolled slab provided in Example 1 of the present invention.

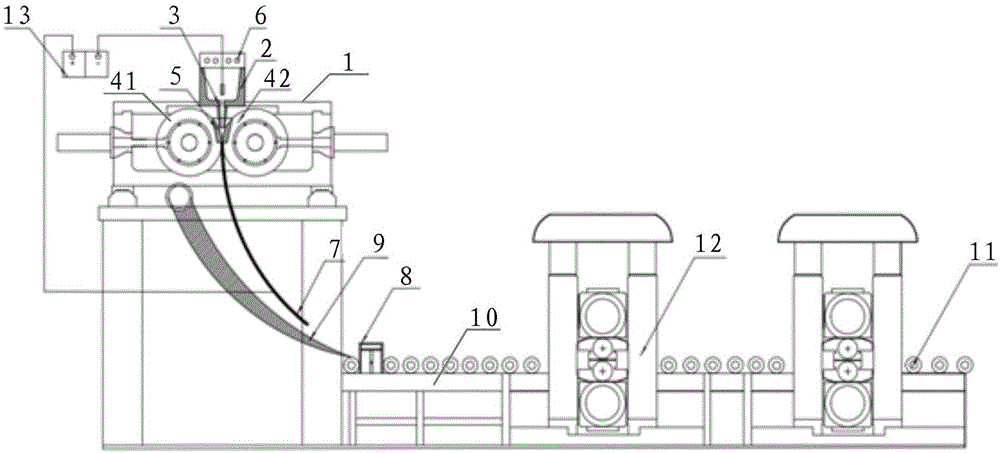

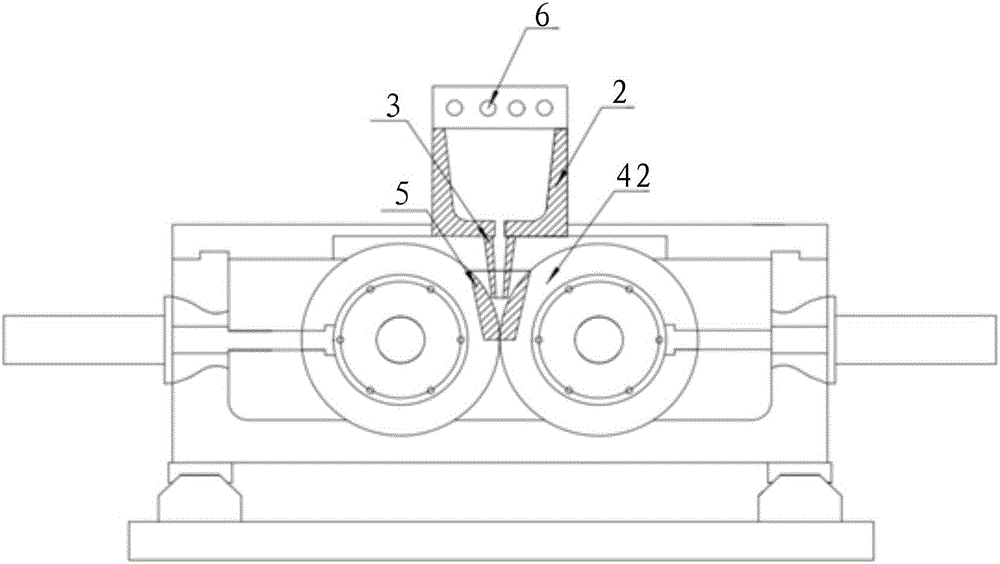

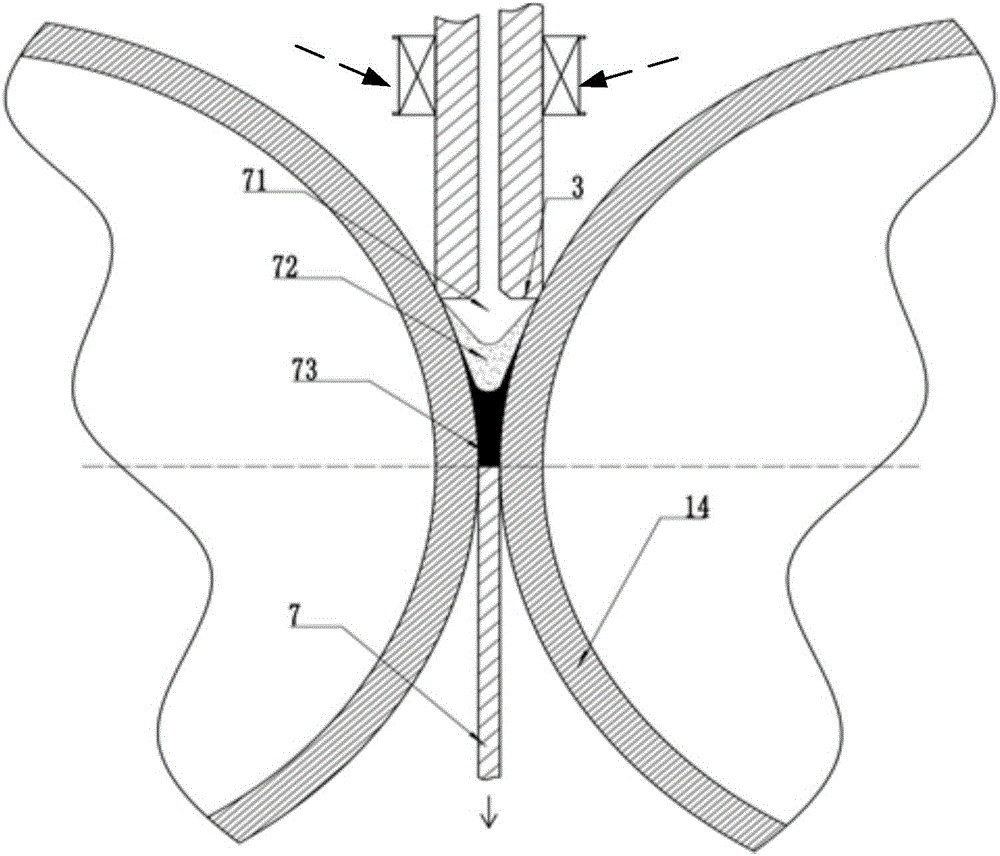

[0060] A vertical semi-solid casting and rolling device for aluminum alloy plates and strips, such as figure 1 As shown, it includes: heater 6, launder 2, casting nozzle 3, side sealing plate 5, left and right casting rolls (41, 42) with cooling water, arc guide plate 9, shearing device 8 , Rolling mill 12, horizontal roller table 11, pulse power supply device 13, casting and rolling strip 7.

[0061] The vertical semi-solid casting and rolling method of the AA6111 aluminum alloy plate and strip with a strip thickness of about 6mm, the specific operation steps are as follows:

[0062] Ingredients smelting: according to the standard composition (wt%) of AA6111 aluminum alloy Si: 1.20, Mg: 0.7, Cu: 0.7, Mn: 0.2, Fe: 0.2, Ti: 0.1, Al balance, industrial pure aluminum ingots, pure Magnesium ingots, aluminum-copper master allo...

Embodiment 2

[0067] Figure 6 A schematic diagram of the microstructure of the AA6016 aluminum alloy cast-rolled slab provided in Example 2 of the present invention.

[0068] The vertical semi-solid casting and rolling method of the AA6016 aluminum alloy plate and strip with a strip thickness of about 10mm, the specific operation steps are as follows:

[0069] Ingredients smelting: according to the standard composition (wt%) of AA6016 aluminum alloy Si: 1.20, Mg: 0.7, Cu: 0.2, Mn: 0.2, Fe: 0.2, Ti: 0.1, Al balance, industrial pure aluminum ingots, pure Magnesium ingots, aluminum-copper master alloys, aluminum-silicon master alloys, manganese agents, iron agents, and aluminum-titanium-boron master alloys are weighed in proportion, and industrial pure aluminum ingots are first put into the melting furnace for melting, and the temperature is set The value is 750°C. After the pure aluminum ingot is completely melted, add the above-mentioned various intermediate alloys and metal additives in o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com