Method for producing high thermokeeping continuous casting protective slag

A technology of continuous casting mold powder and production method, which is applied to the production field of high thermal insulation continuous casting mold powder, can solve problems such as affecting thermal insulation performance, and achieve the effects of improving thermal insulation performance, increasing continuous casting speed, and reducing slag consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

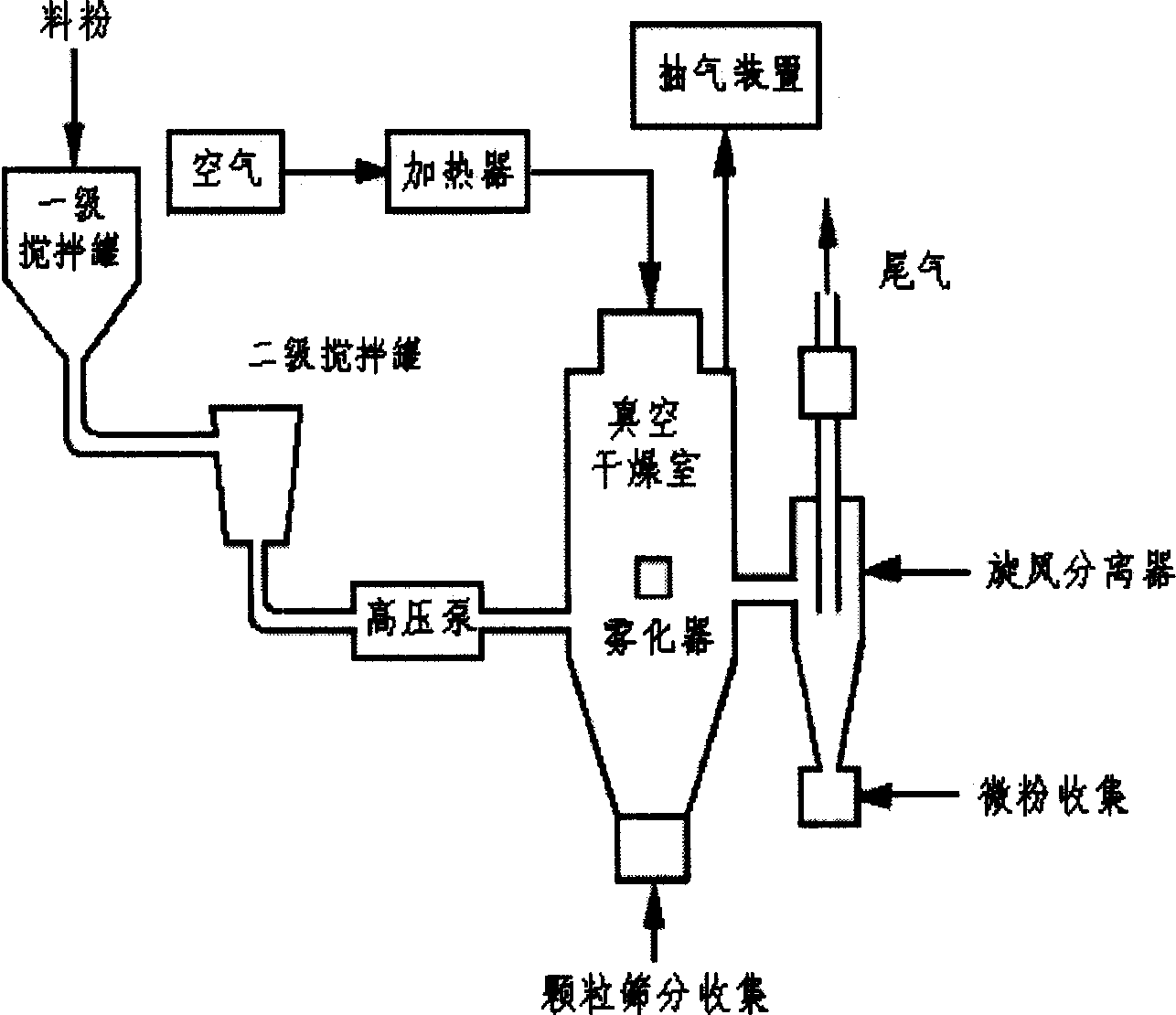

[0008] Such as figure 1 Shown, this method step is as follows: (a) raw material ratio: limestone powder 16%, sodium carbonate powder 18%, carbon black 2%, graphite 8%, wollastonite powder 38%, corundum powder 4%, magnesia powder 2% %, 7% fluorite powder, 2% iron ore powder, and 3% binder; (b) Put the prepared raw materials into the cone mixer and mix for 60-100 minutes, then put the stirred powder Finely grind in a barrel mill for 20 to 50 minutes to make the powder particle size ≤ 200 mesh; (c) put the ground powder ≤ 200 mesh into the first-stage mixing tank according to the powder containing 30 to 70% (weight) Mix and stir for 60 to 100 minutes with a ratio of 70 to 30% water, then transfer from the primary stirring tank to the secondary stirring tank and stir for 15 to 30 minutes; Under the pressure of 10 MPa, use atomizing nozzles in a vacuum drying room with a vacuum degree of 0-380mmHg and a temperature of 600-700°C to spray and granulate into hollow continuous casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com