Double-acting hydraulic stretcher for composite cylinder

A composite cylinder and stretching machine technology, applied in the field of hydraulic stretching machine and composite cylinder double-action hydraulic stretching machine, can solve the problems of complex mechanism and many hydraulic cylinders, and achieve the effects of small size, low cost and convenient debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

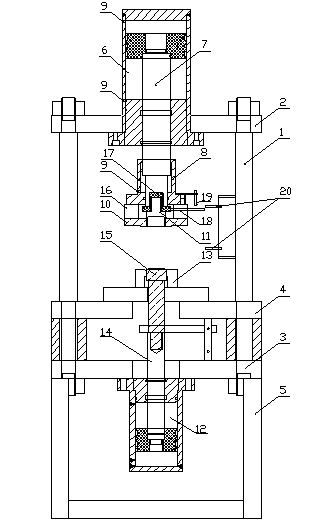

[0013] The present invention comprises the frame that is made of four parallel upright columns 1 and upper fixing plate 2, lower fixing plate 3, workbench 4 and base 5, and upper fixing plate 2 is installed a two-way hydraulic cylinder master cylinder hydraulic cylinder 6, master cylinder The lower end of the piston rod 7 of the hydraulic cylinder runs through the blanking cylinder sleeve 8 to form a blanking hydraulic cylinder. The hydraulic cylinder sleeve 8 is provided with an oil delivery hole 9. The lower end of the hydraulic cylinder sleeve 8 is connected to the upper blanking die 10 through screws, and the main cylinder hydraulic cylinder The lower end of the piston rod 7 is provided with an upper mold 11, and a two-way hydraulic cylinder is installed under the lower solid plate 3 as the ejection hydraulic cylinder 12, and the workbench 4 is provided with a lower mold 13 corresponding to the upper mold 11 to eject the hydraulic cylinder piston. The head of the rod 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com