Silicon-plastic composite cylindrical particles prepared from power plant waste and method for preparing plastic plate thereof

A technology of plastic sheet and production method, which is applied in the field of resources and environment, can solve problems such as restricting the development of renewable power plants, primary pollution, secondary pollution, etc., and achieve the effect of eliminating machine jamming, increasing enterprise output, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: take 1000 kilograms as the base feeding ratio as follows:

[0030] The purpose of this example is to change the traditional granulation production method of waste plastic composite materials, change the irregular raw materials into smooth surface and high hardness granular materials, and make them easy to produce and process composite product raw materials, so as to facilitate the production of composite products industrial production needs.

[0031] A silicon-plastic composite cylindrical particle made of waste plastics, fly ash, and slag as raw materials in this embodiment includes cylindrical particles made of waste plastics as the main raw material. The appearance of the substrate is black, and the surface particles Round, uniform, high hardness, and its smoothness is far superior to irregular raw materials, which is conducive to mechanical processing, storage, handling and transportation.

[0032] In the present embodiment, what calcium carbonate ado...

Embodiment 2

[0033] Embodiment 2: take 1000 kilograms as the base feeding ratio as follows

[0034] In this embodiment, a waste plastic, fly ash, and slag are combined with cylindrical particles to make a plate, which includes using waste plastics as the main raw material to make cylindrical particles as a matrix. The appearance of the matrix is black, and the surface particles are round, uniform, and With high hardness, its smoothness is far superior to irregular raw materials, which is conducive to mechanical processing, storage, handling and transportation.

[0035] In this embodiment, the matrix components include plastics, fly ash, and calcium carbonate. According to their weight percentages, in the matrix: 50% of waste plastics, 500 kg; 40% of fly ash, 400 kg; 10% of calcium carbonate , 100 kg.

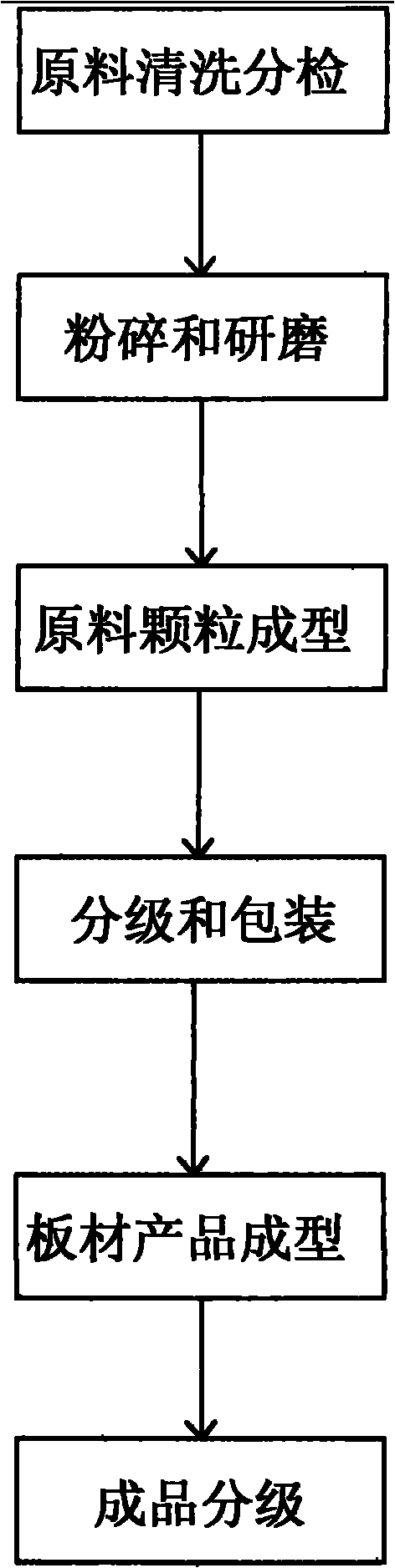

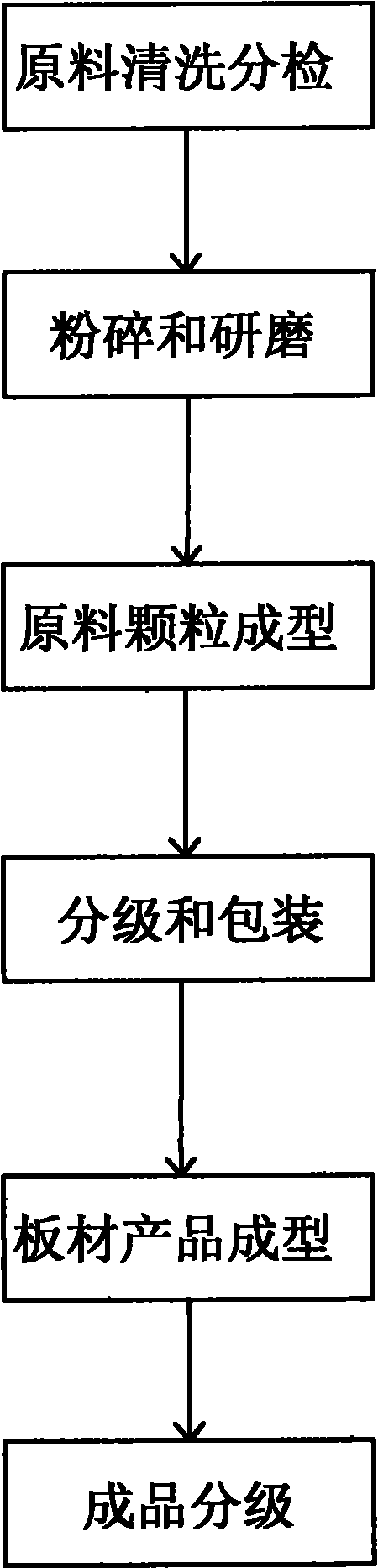

[0036] Referring to Fig. 1, according to the proportioning of raw materials, its above-mentioned two embodiment manufacturing methods, its method step is as follows:

[0037] (1) Cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com