Semi-coke three-cylinder dryer

A three-cylinder dryer and blue carbon technology, which is applied in the field of dryers, can solve the problems of affecting the drying efficiency of the blue carbon three-cylinder dryer, reducing the economic value of blue carbon, and the high rate of blue carbon breakage, so as to reduce the breakage efficiency, increase economic value, and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

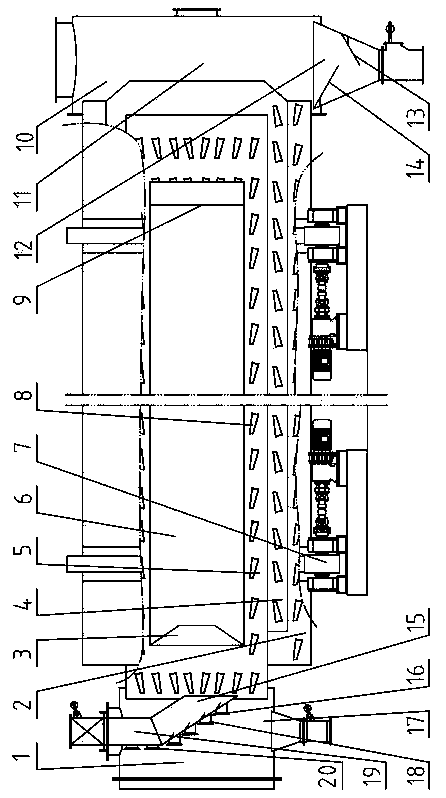

[0007] figure 1 Among them, a blue carbon three-cylinder dryer includes a composite cylinder, a transmission device 7, a feeding device 1 and a discharging device 10. The composite cylinder contains three outer cylinders 2, middle cylinders 4 and inner cylinders 5 with different diameters from large to small. The middle cylinder body 4 is located in the outer cylinder body 2, the inner cylinder body 5 is located in the middle cylinder body 4, the outer cylinder body 2, the middle cylinder body 4 and the inner cylinder body 5 are coaxial, the outer cylinder body 2, the middle cylinder body 4 and the inner cylinder body Spiral lifting plates 8 are provided on the inner wall of the cylinder body 5 . The compound cylinder body is placed on the transmission device 7, and the feeding device 1 is made of a feeding pipe and a cover shell 17, and the feeding pipe is made of an upper pipe 19 and a lower pipe 15. Upper tube 19 is arranged on the top of cover shell 17, and the upper mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com