Composite cylinder cover

A cylinder head, composite technology, applied in the direction of cylinder head, cylinder, engine components, etc., can solve the problems of high manufacturing technology, process technology requirements, cooling effect of the nose bridge area, and complex structure of the cylinder head, so as to eliminate cylinder gaskets Ablation failure, improved cooling effect, and reduced assembly technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

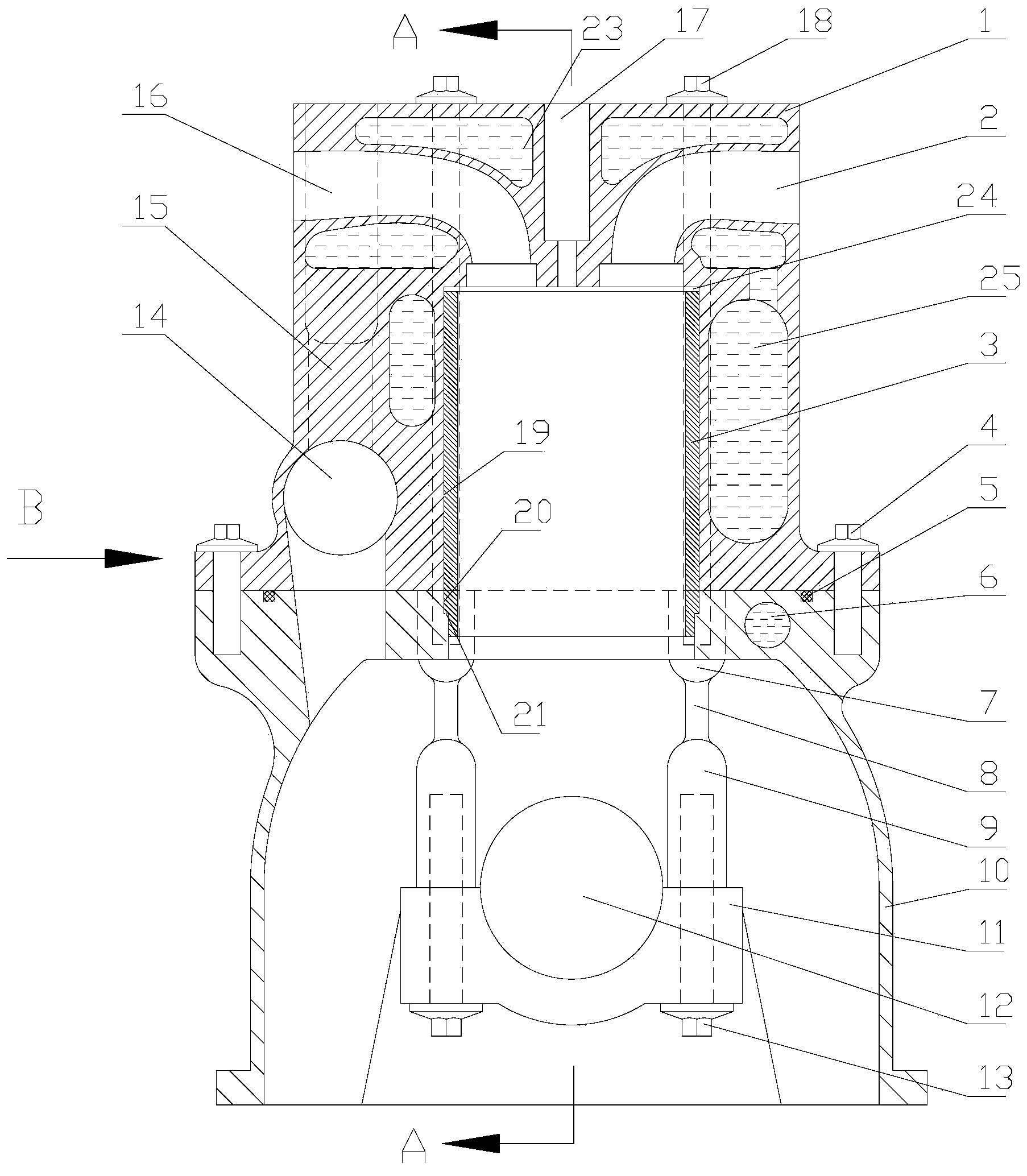

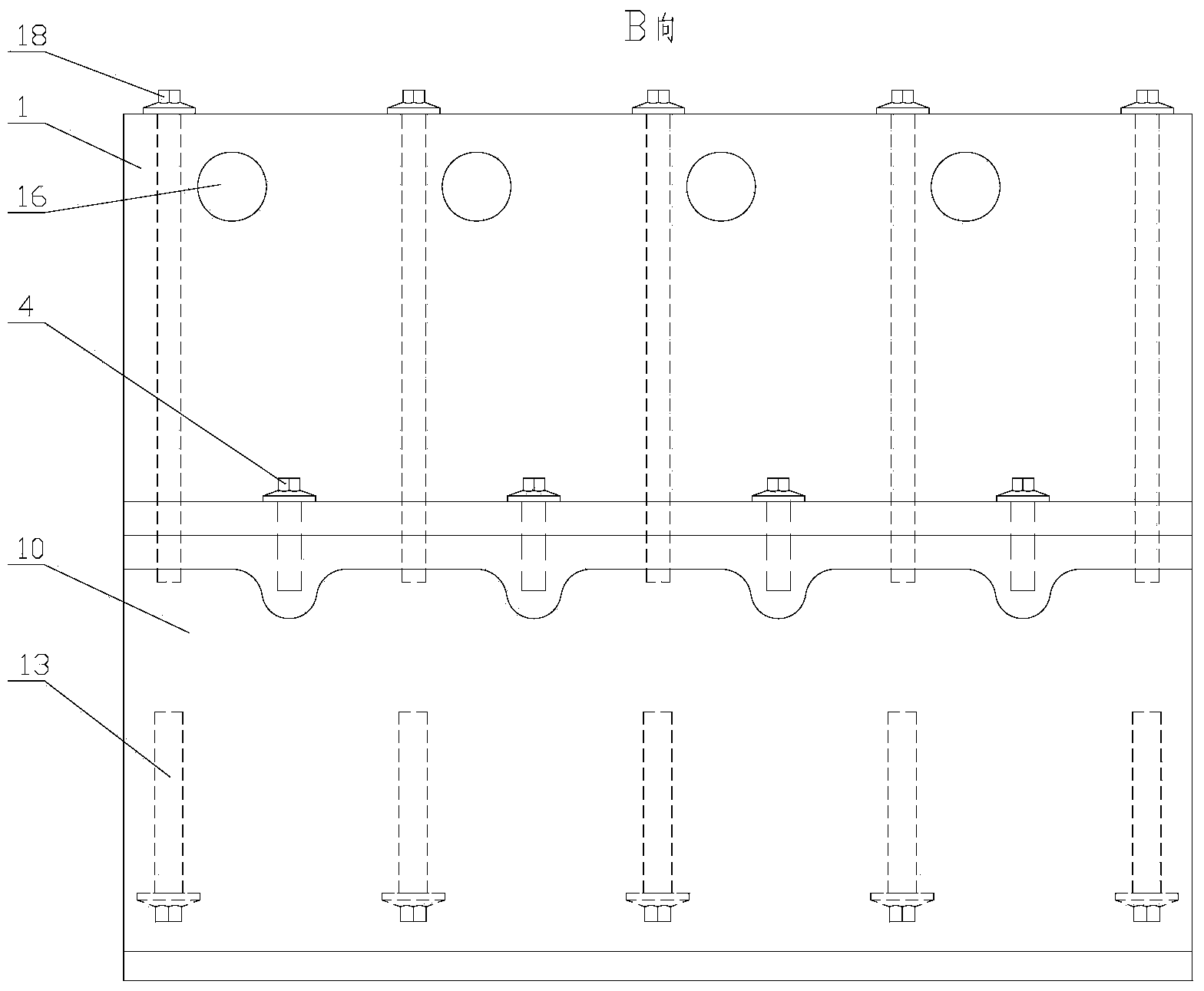

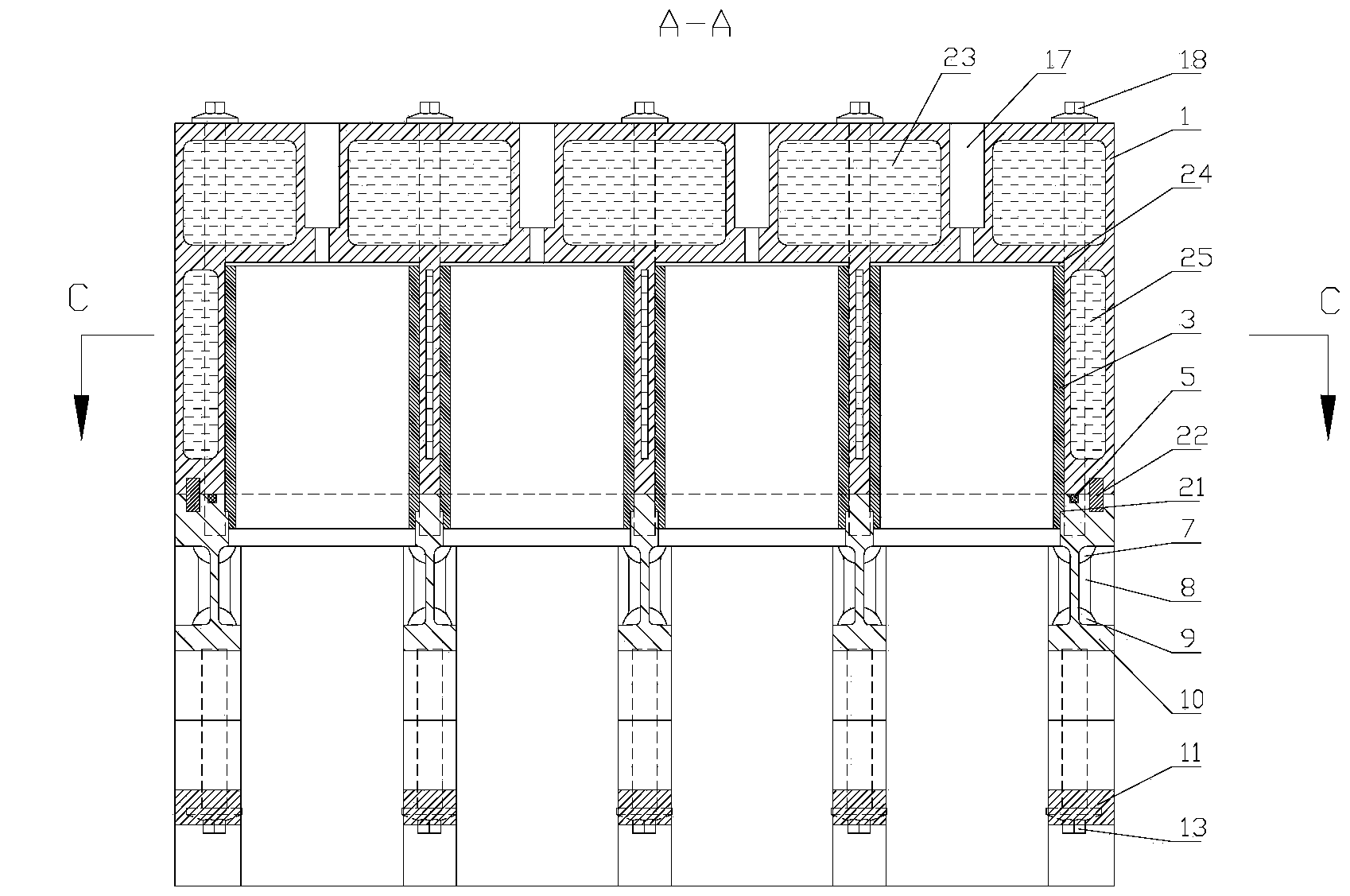

[0027] Such as figure 1 As shown, the composite cylinder head 1 according to the specific embodiment of the present invention can be directly installed on the crankcase 10 to form the body of the internal combustion engine, and the piston in the crankcase 10 can directly extend into the cylinder bore 19 to reciprocate. The cover 1 itself integrates all the intake passages 2, exhaust passages 16, fuel injector installation holes 17, cylinder head water jacket 23 and valve installation structure (not shown in the figure) of the traditional cylinder head. The valve installation structure can be an existing Have structure, be fixed on the top of this composite cylinder head 1 and get final product. Also integrated cylinder bore 19, cylinder bore water jacket 25, camshaft bore 14 and tappet bore 15 (see Figure 4 ). In this embodiment, the intake passage 2 and the exhaust passage 16 are arranged on both sides of the upper end of the cylinder head, and the fuel injector installati...

Embodiment 2

[0030] Such as figure 1 As shown, the body according to the specific embodiment of the present invention includes the composite cylinder head 1 and the crankcase 10 provided in Embodiment 1, the composite cylinder head 1 is installed on the upper end of the crankcase 10, and the upper end of the crankcase 10 is connected to the crankcase 10. The cylinder hole 19 on the composite cylinder head 1 is provided with a cylinder hole extension 20 at the corresponding position, and the cylinder hole 19 on the composite cylinder head 1 and the cylinder hole extension 20 form a body cylinder hole (not marked in the figure). The upper end surface of 10 is provided with a groove 5 for filling the sealant, and the groove 5 can also be arranged on the bottom end surface of the composite cylinder head 1, by filling the sealant in the groove 5 and the composite cylinder head 1 and the crankshaft The tight connection of the box 10 achieves the effect of sealing. As a preferred embodiment, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com