Tow prepreg tape winding laying process

A prepreg tape and process technology, applied in the field of composite material rotary parts, can solve the problems of appearance and quality, poor working environment, high material cost, etc., to increase the function of zero-degree angle laying, simplify the winding process and equipment, expand The effect of mechanical space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

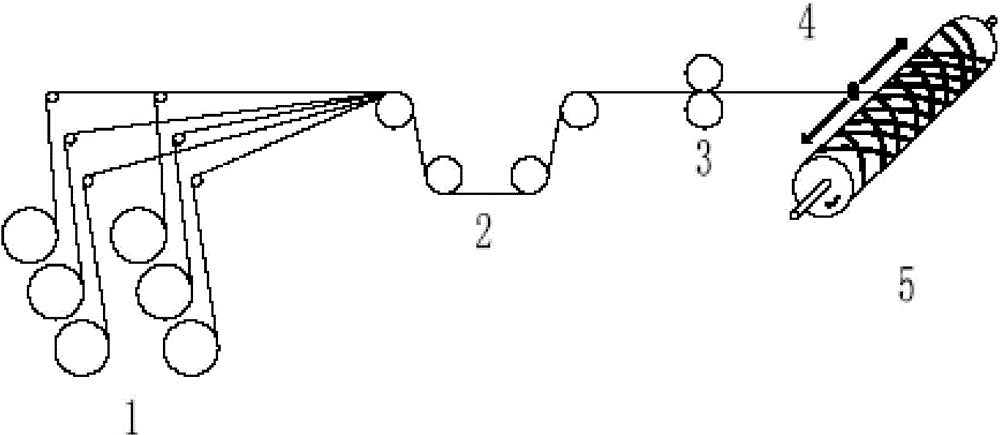

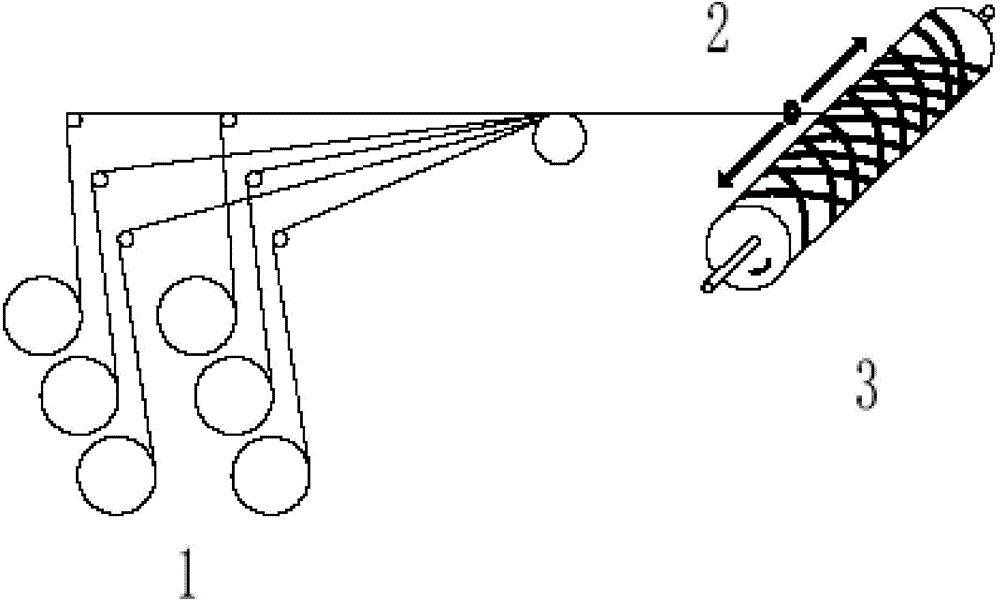

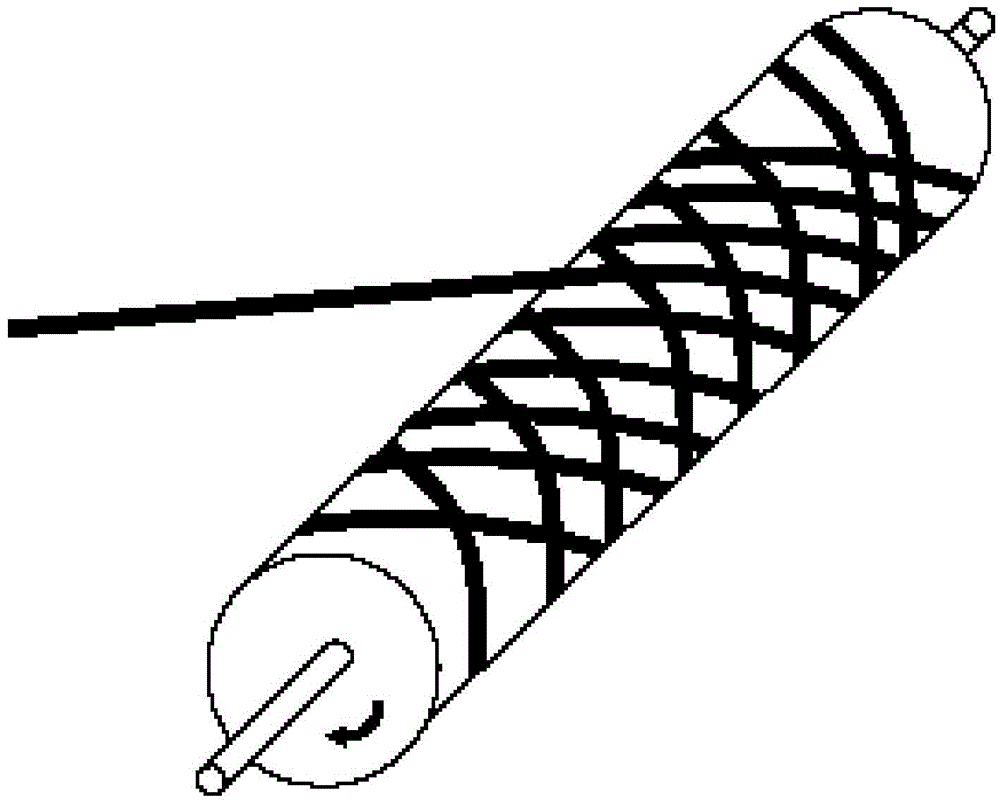

[0012] A tow prepreg tape winding and laying process of the present invention, such as figure 2 shown. The tow prepreg tape passes through the constant tension tangential unwinding creel (1), and pulls one or more tow prepreg tapes to the guide head (2). Winding is realized on the mold core to form a wound product (3). When the mold core stops rotating, the guide head with elastic pressing roller presses the tow prepreg tape on the mold core, moves back and forth, and cuts the tow at the folded place The prepreg tape, re-headed, is pressed against the prepreg tape with a pressure roller and laid in the other direction. Due to the viscosity of the tow prepreg tape, it can be well bonded to the core or the previous wrapping layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com