Single crystal furnace capable of improving czochralski-method single crystal growth speed

A growth rate and single crystal furnace technology, which is applied in the field of single crystal furnaces to increase the growth rate of Czochralski single crystals, can solve the problems of increasing heater power, increasing labor intensity of production workers, and easy splashing of silicon melt, etc., to reduce Effect of heater power, reduction of heat loss, and ease of cleaning and charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

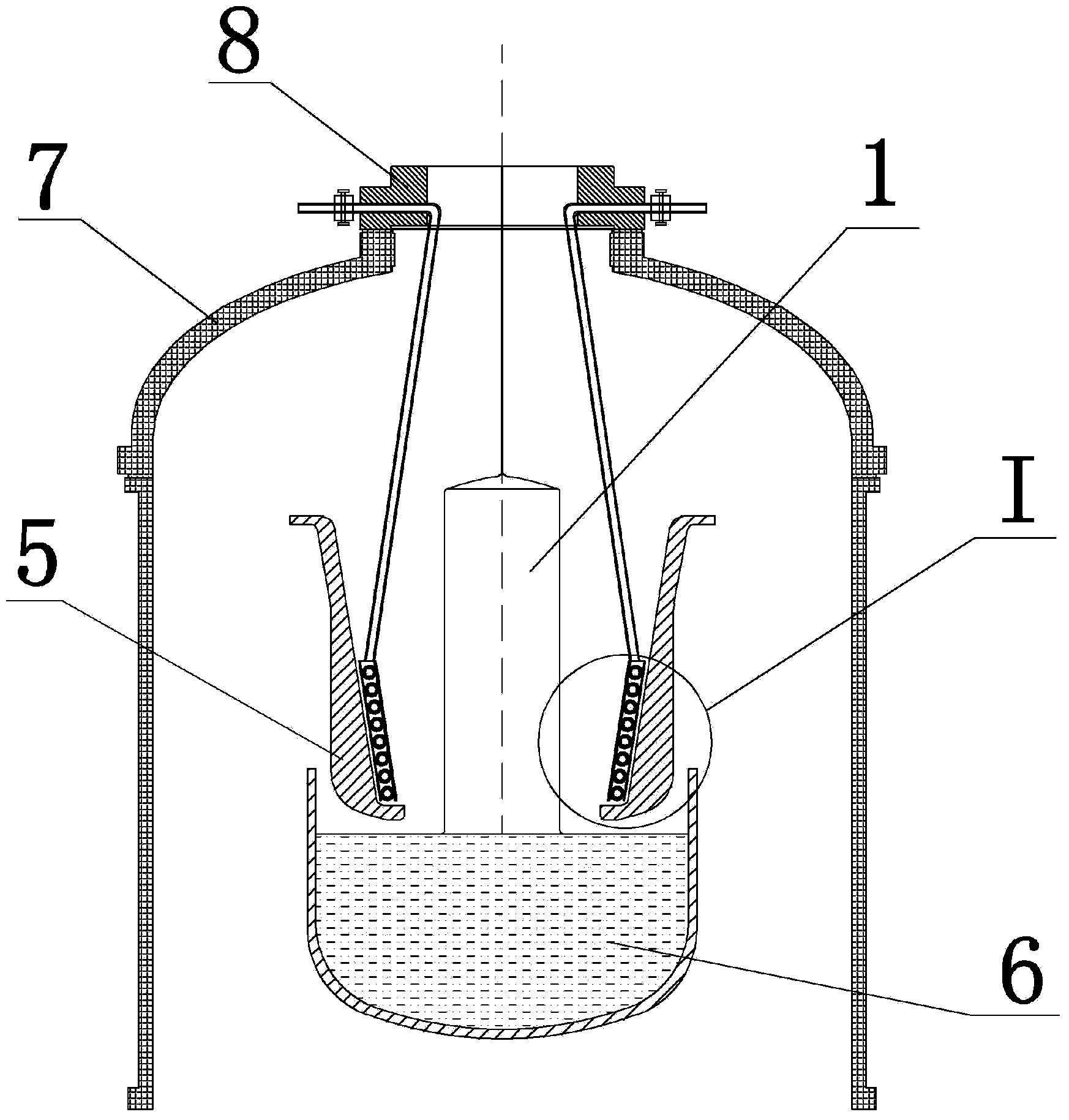

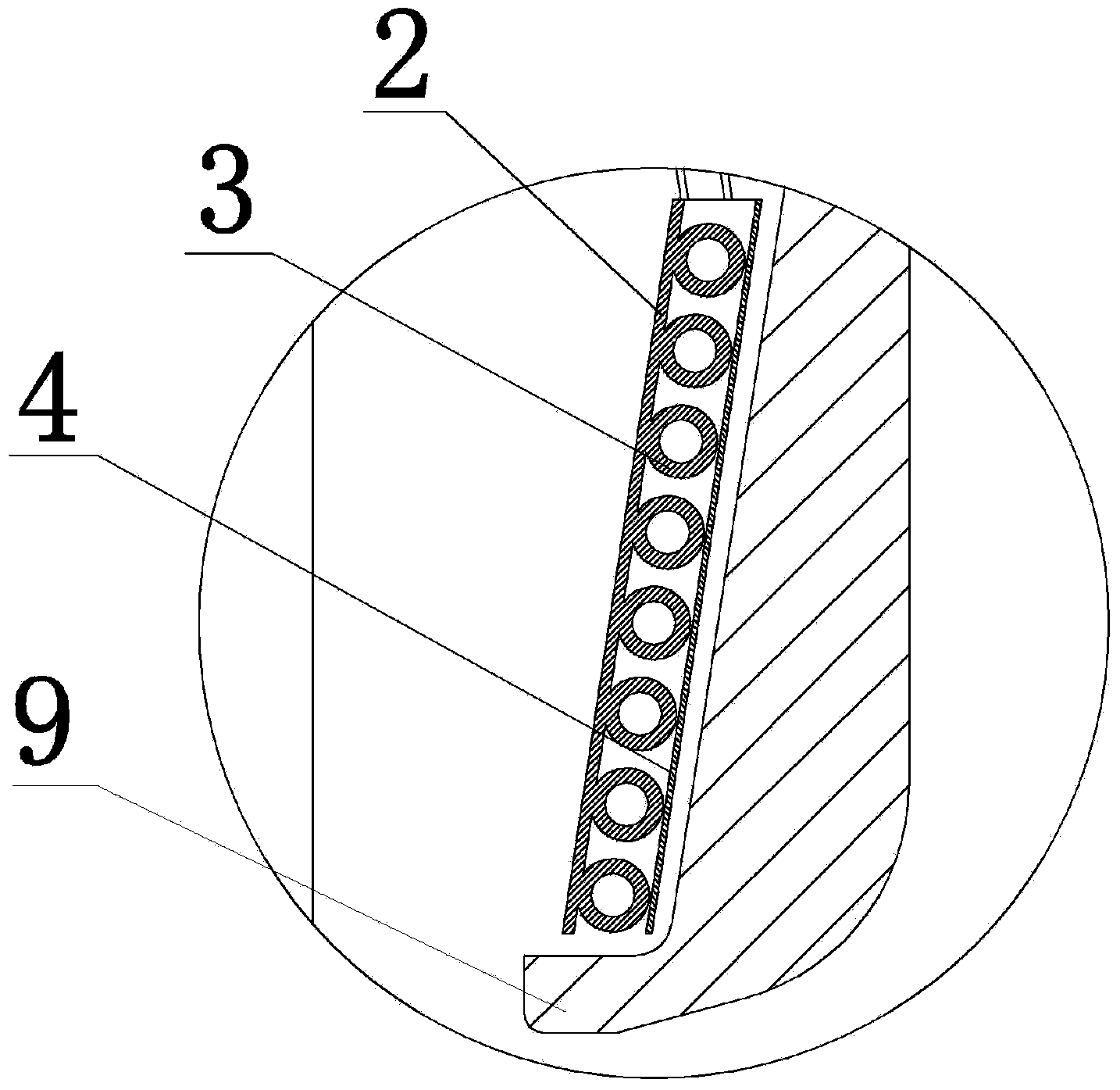

[0043] like figure 1 and figure 2 As shown, this embodiment is a single crystal furnace for improving the growth rate of Czochralski method single crystal, which includes a guide tube, and a cooling device is arranged in the guide tube, and the cooling device is composed of three-layer components with a taper , the outermost layer is a molybdenum cylinder 4, the middle layer is a hollow wound copper tube 3 with internal cooling water (the cooling medium includes but not limited to water, and other cooling fluids such as argon or helium), and the innermost layer is Copper cylinder 2. The gap between the inner side of the molybdenum cylinder 4 and the wound copper pipe 3 is 0-30 mm, and the gap between the outer side of the molybdenum cylinder 4 and the guide tube 5 is 0-30 mm. The coiled copper pipe 3 through which cooling water is passed inside has a taper of 0° to 80°, such as Figure 5 As shown, it is wound in a spiral shape. After winding, it passes out of the furnace ...

Embodiment 2

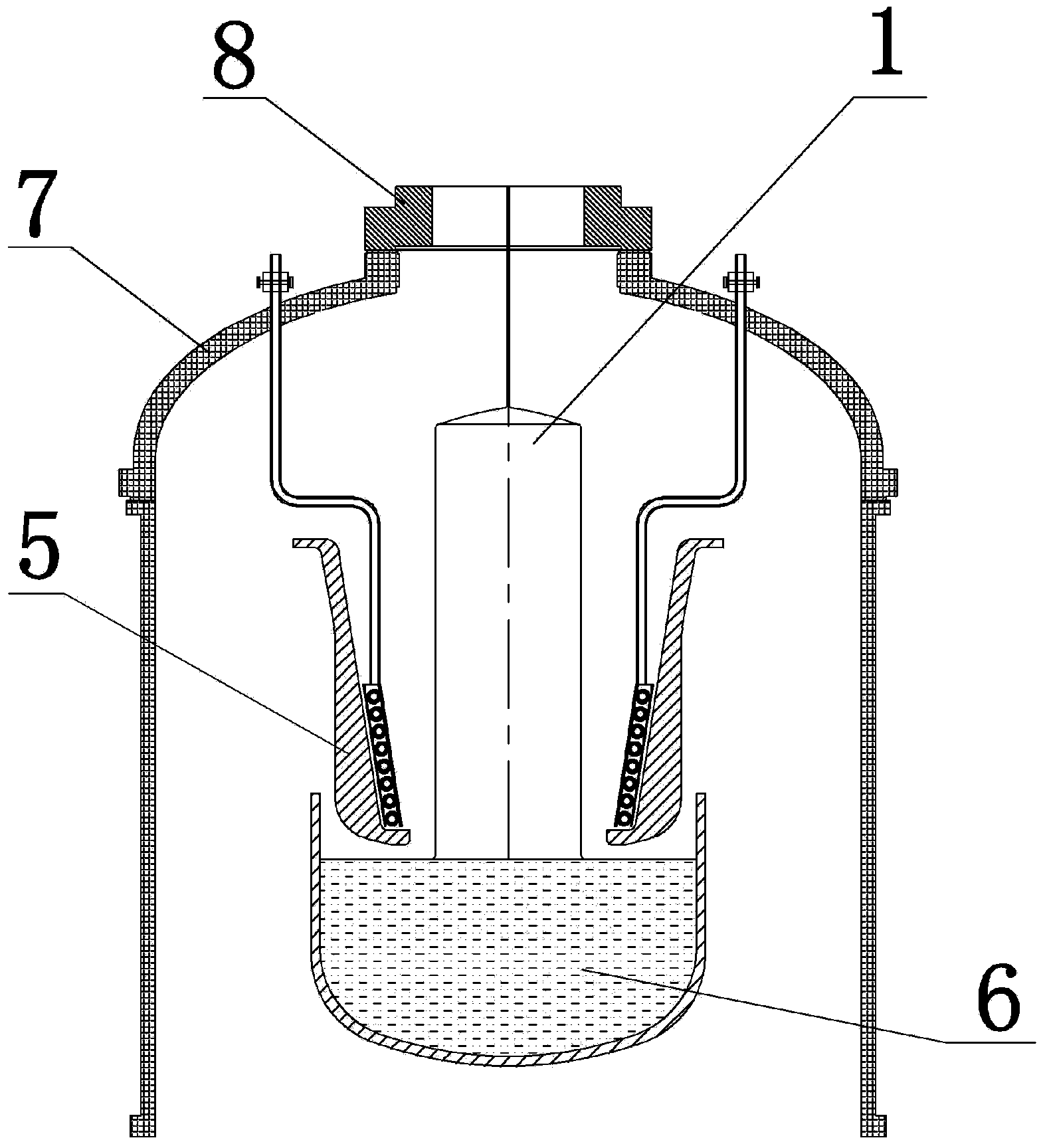

[0046] like image 3 As shown, there is another way for the wound copper tube 3 of the cooling device in the single crystal furnace in this embodiment to pass out of the single crystal furnace. The coiled copper pipe 3 through which the cooling water flows inside is wound in a spiral shape, and passes out of the furnace cover 7 of the single crystal furnace after winding, and is then connected with the cooling water inlet and outlet pipelines of the furnace platform equipment. All the other parts are identical with embodiment 1.

Embodiment 3

[0048] like Figure 4 As shown, the outermost layer of the cooling device in the single crystal furnace in this embodiment is a molybdenum cylinder 4, the middle layer is a copper cylinder 2, and the innermost layer is a wound copper tube 3 through which cooling water passes. The gap between the inside of the molybdenum cylinder 4 and the copper cylinder 2 is 0-30 mm, and the gap between the outside of the molybdenum cylinder 4 and the guide tube 5 is 0-30 mm. The coiled copper pipe 3 through which cooling water is passed inside has a taper of 0° to 80°, such as Figure 5 As shown, it is wound in a spiral shape, and after winding, it is passed out of the furnace from the furnace cover connecting flange 8 or furnace cover 7 of the single crystal furnace, and then connected to the cooling water inlet and outlet pipelines of the furnace platform equipment. There is sufficient surface contact between the wound copper tube 3 and the copper cylinder 2, the cross section of the wound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com