Energy-saving high-current electromagnetic relay

An electromagnetic relay, high-current technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of high failure rate, short service life, large volume, etc., and achieve high insulation withstand voltage level and long service life. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

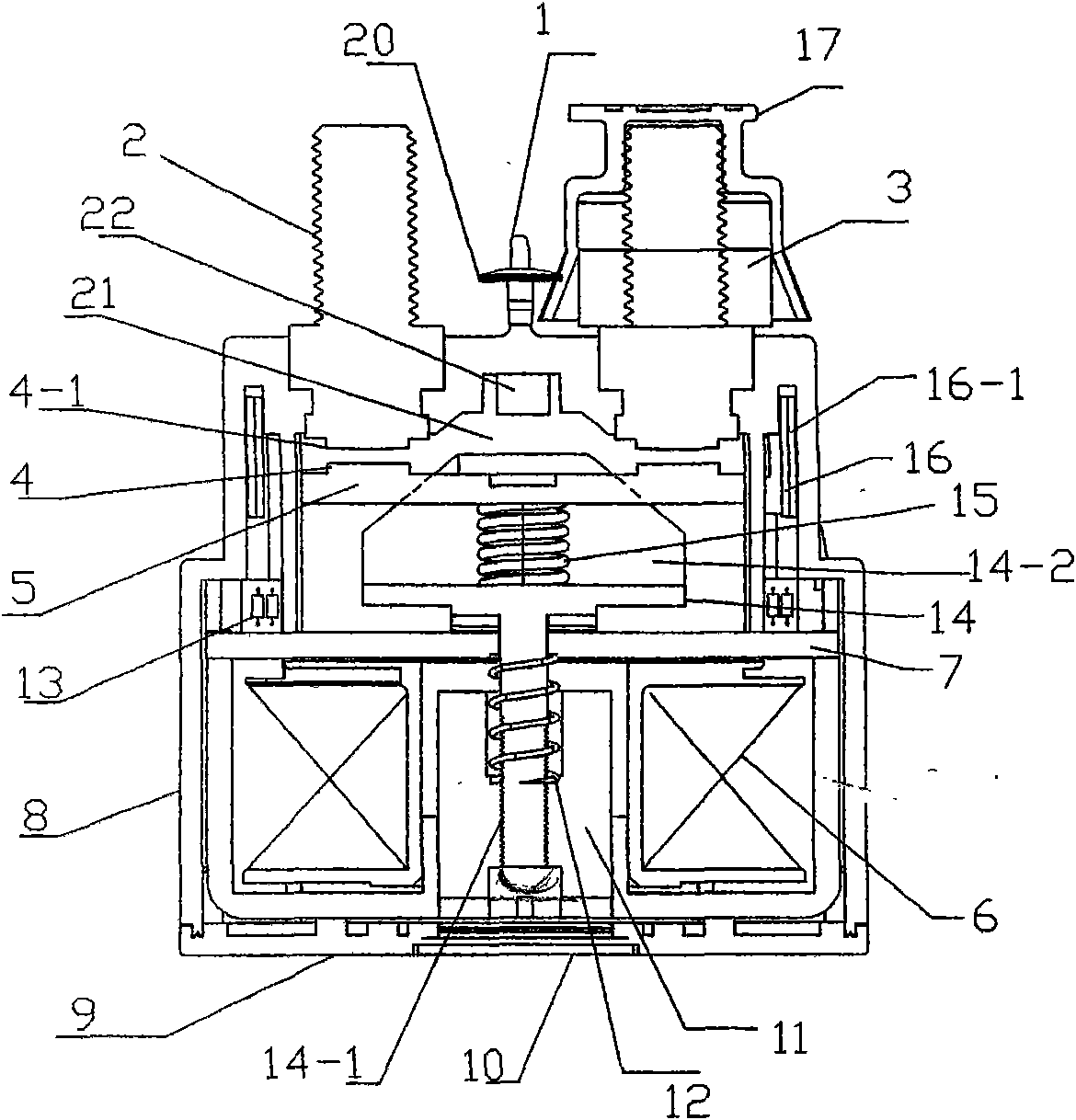

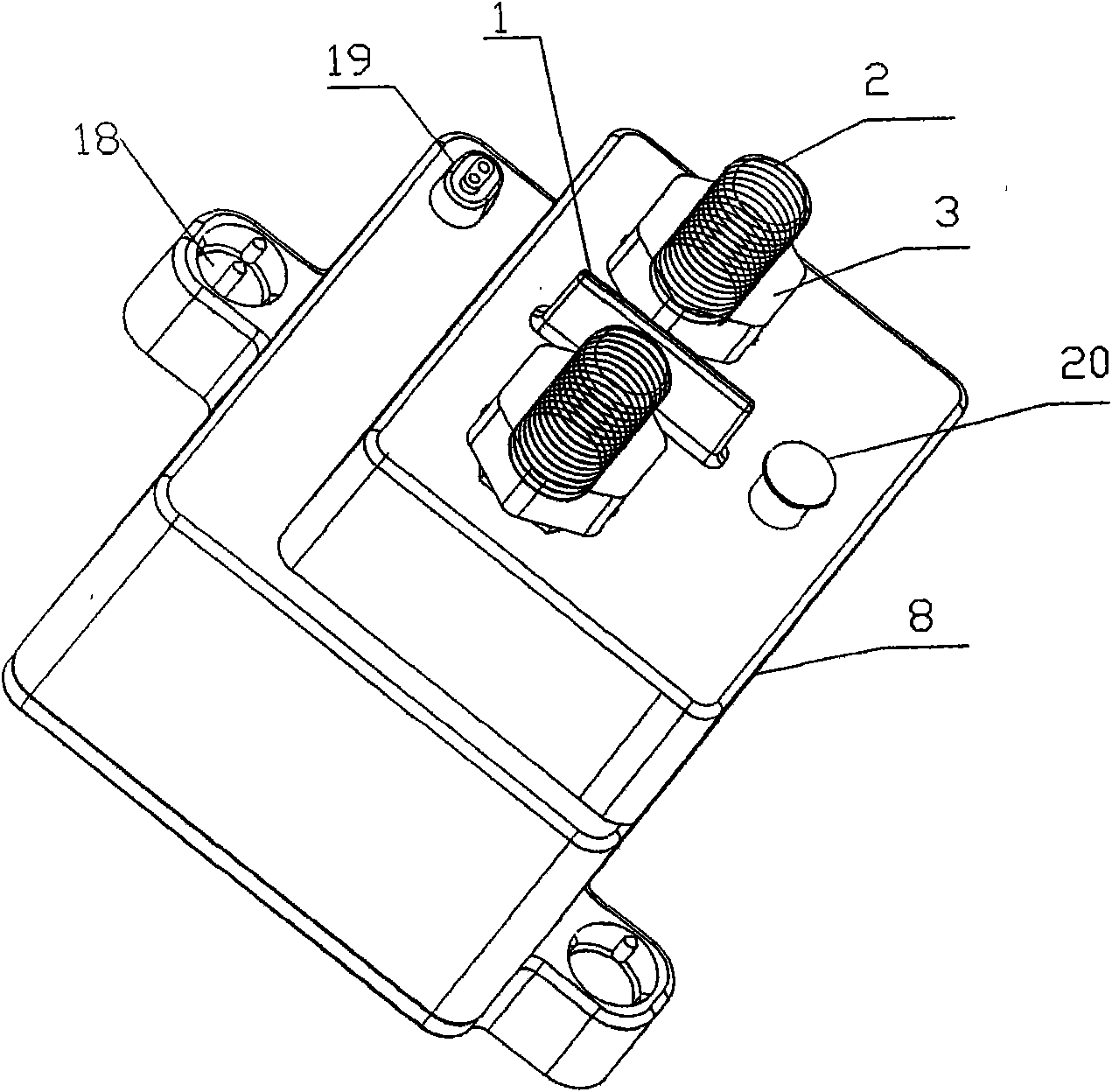

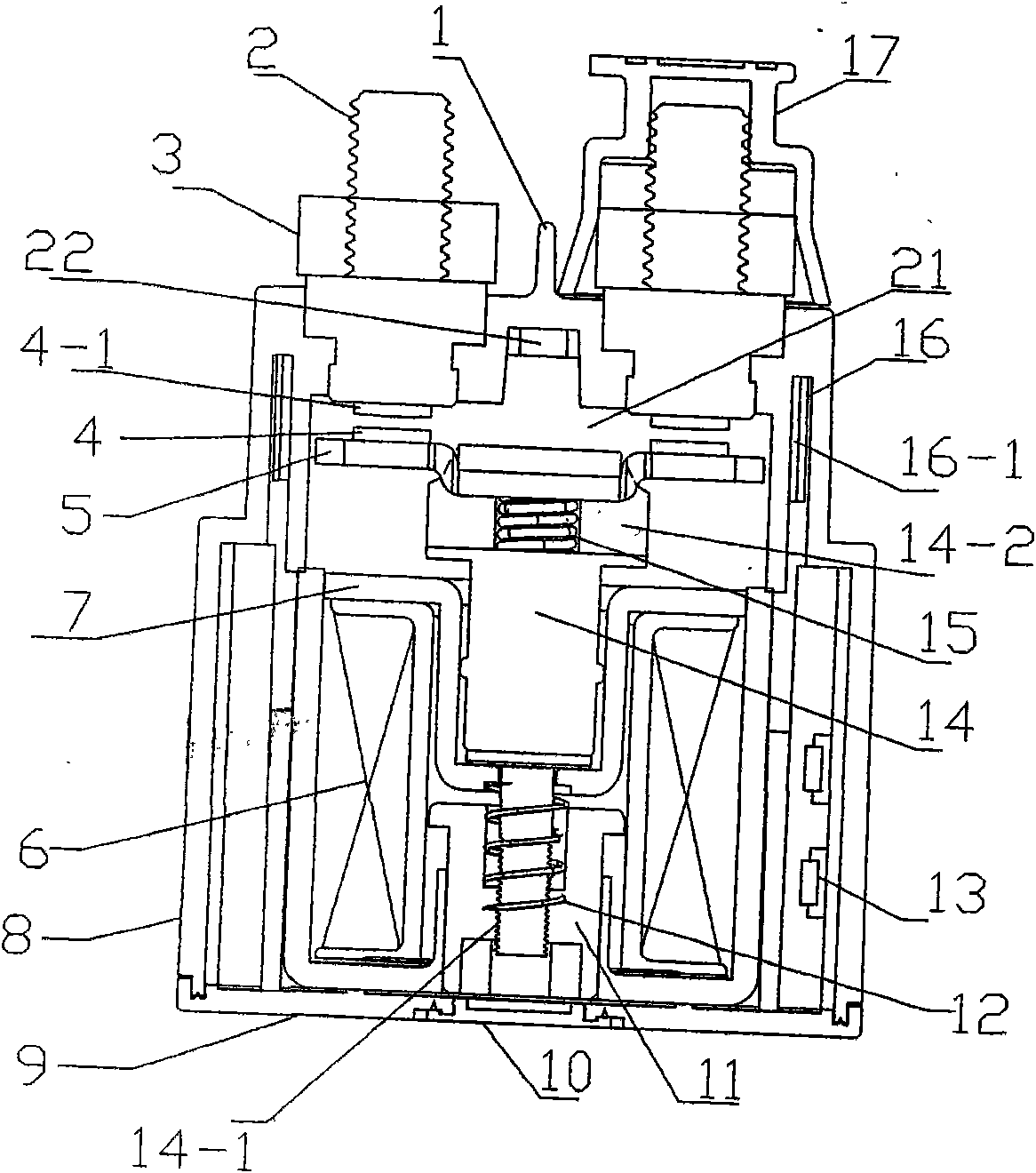

[0012] The present invention uses engineering plastics to inject into a stepped shell 8, and two copper stud bolts 2 are fixed by parallel injection molding on the top of the shell, and each bolt is respectively equipped with a compression nut 3 for input and output of a large current. Also equipped with a rubber protective cap 17 that can cover the nut and its bolt head respectively, a partition wall 1 is provided on the shell between the two protective caps, and an inner coil 6 and a bottom surface are installed below the inner steps of the shell. The lower magnetic yoke 7 is concaved into a cylindrical shape. A moving iron 11 with a concave upper surface is installed in the concave cylinder of the lower magnetic yoke. A push frame 14 is installed on the same center of the lower magnetic yoke. Rod 14-1 passes through the center hole of the lower yoke and is connected to the moving iron screw by the return spring 12 installed in the concave cylinder of the moving iron. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com