Two-way integrated embedded chip rerouting POP packaging structure and manufacturing method thereof

A packaging structure and rewiring technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problem of low precision of laser drilling and electroplating blind hole process, easily deformable thickness of substrate, unfavorable packaging integration degree, etc. problems, to achieve better product performance, better electrical and heat dissipation performance, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

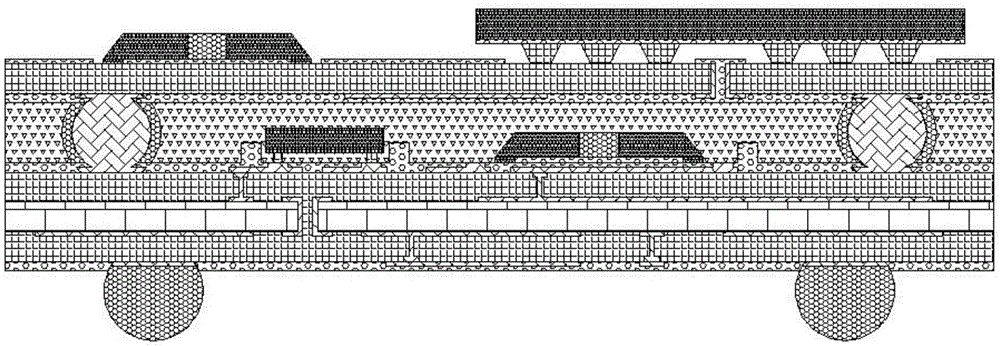

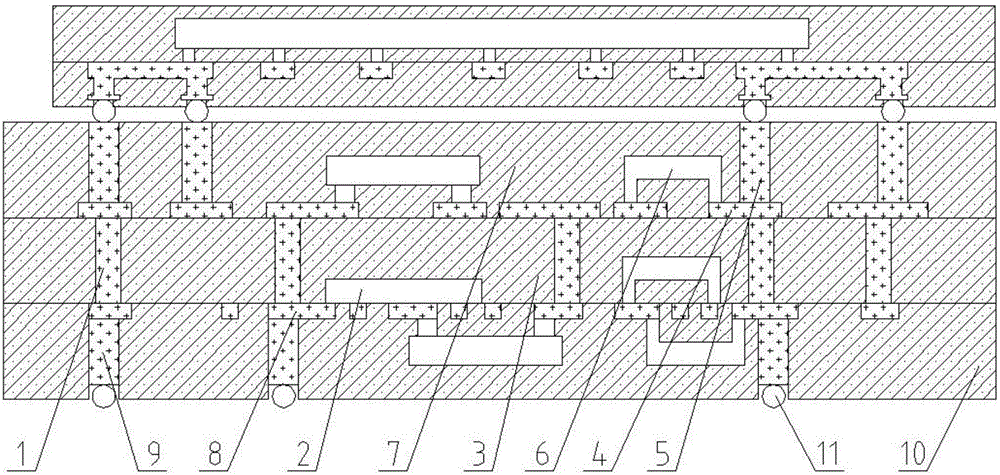

[0051] like figure 2 As shown, a bidirectional integrated embedded chip redistribution POP package structure in this embodiment includes a first package body and a second package body, the first package body includes a second circuit layer 8, and the first package body includes a second circuit layer 8. The front side of the second circuit layer 8 is provided with a first connecting copper column 1 and a first component 2, and the periphery of the first connecting copper column 1 and the first component 2 is encapsulated with a first insulating material 3, and the first insulating material 3. A first circuit layer 4 is provided on the front side, and a second connection copper column 5 and a second component 6 are provided on the front side of the first circuit layer 4, and the outer periphery of the second connection copper column 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com